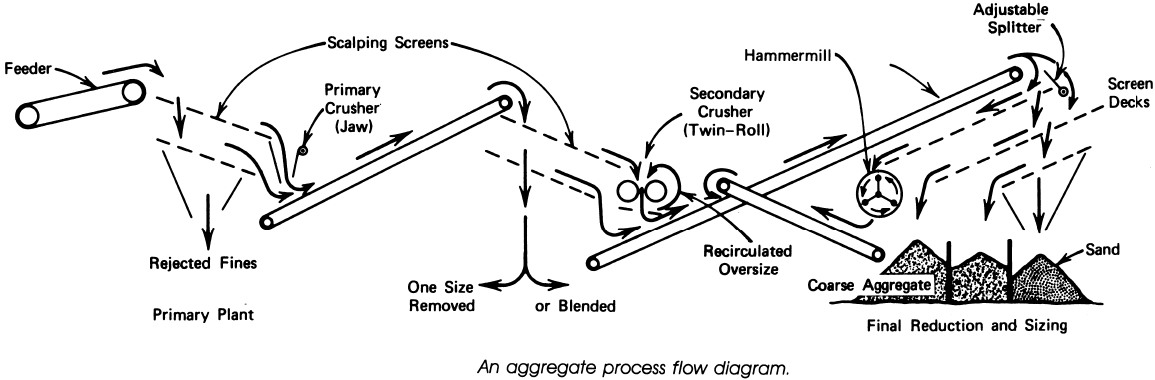

The following example demonstrates a method of selecting the components of an aggregate plant. Good component efficiency and part performance pre-evaluation is essential to a solid design. The aggregate production requires the consideration of several crushers, feeders and screens. This is not intended to be a typical situation, though it does involve common crusher and screen units often used in aggregate plants.

Crushing & Screening Plant Assessment Example

Quarry rock of 12 in. maximum size is to be handled in a two-stage crusher plant at the rate of 70 tons per hour. The maximum size of output is to be 1½ in., and separation of materials over 1 in. size and the minus 1 in. in the output is required. Select a jaw crusher like those included in this table.

Capacities and Horsepower of Jaw Crushers (tons/hr)

|

Crusher Size (in.) |

Power Required (hp) |

Closed Side Setting (in.) |

||||||||

|

2 |

3 | 4 | 5 | 6 | 7 | 8 | 9 |

10 |

||

|

2036 |

75 | 45 | 70 | 100 | 125 |

150 |

||||

|

2042 |

75 | 60 | 85 | 120 | 150 |

180 |

||||

|

2436 |

100 | 55 | 80 | 110 | 145 |

175 |

||||

|

2448 |

100 | 115 | 155 | 195 | 230 | 260 |

315 |

|||

|

3048 |

150 | 180 | 220 | 260 | 315 |

365 |

||||

|

4260 |

200 | 285 | 350 | 420 | 480 | 540 |

600 |

|||

A-C RT Single-toggle Jaw Crusher Specification.

and a twin-roll crusher like those in this table.

Typical Capacities of Twin-Roll Crushers (tons/hr)

|

Crusher Size (in.) |

Power Required (hp) |

Space between Rolls (max. size of feed) (in.) |

||||

|

1/8 (3/8) |

1/4 (3/4) |

1/2 (below) | 1 (below) |

1.5 (below) |

||

|

24 x 16 |

30 | 12 | 24 | 48 (1.25) | 96 (1.75) |

— |

|

30 x 18 |

40 | 13 | 26 | 52 (1 3/8) | 103 (1 7/8) |

156 (2 3/8) |

|

30 x 26 |

100 | 19 | 37 | 75 (1 3/8) | 149 (1 7/8) |

223 (2 3/8) |

|

40 x 22 |

60 | 15 | 31 | 62 (1.5) | 125 (2 1/8) |

187 (2 5/8) |

|

40 x 30 |

200/250 | 21 | 42 | 85 (1.25) | 170 (2 1/8) |

255 (2 5/8) |

From Telsmith Handbook courtesy of Telsmith, Inc

The screens to be considered are a 1½-in. screen with an estimated capacity of 2.7 tph/sq ft and a 1-in. screen with a capacity of 2.1 tph/sq ft. The solution will include the selection of adequate and economical crushers for the two stages and the sizes of screens between them and below the secondary stage.

For the primary crusher a jaw crusher will probably be most economical. A jaw crusher, like 2036 in the Jaw Crusher Table here above, would be able to take the maximum 12 in. size quarry stone but it would not have the required 70 tph capacity needed. To have the needed capacity a jaw crusher like the 2042 or 2436 sizes will have to be selected overloading the secondary crusher.

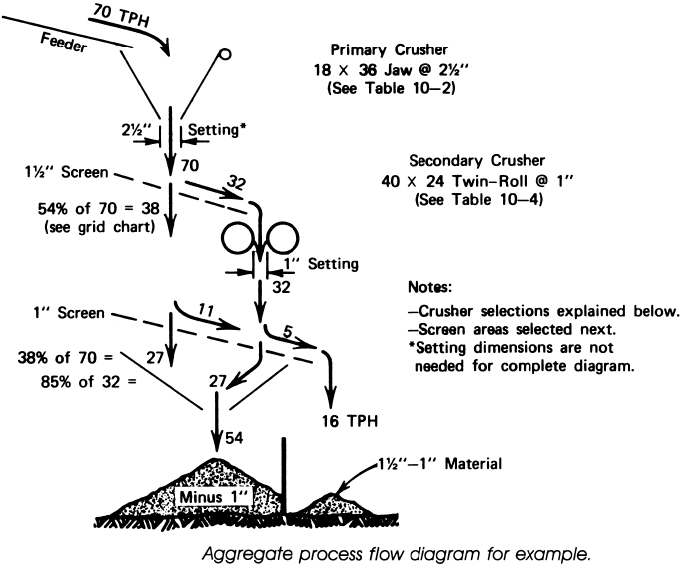

A grid chart or curve for the selected crusher shows that, for a 2½-in. setting, 54% of the material will pass a 1½-in. screen, or 46% will be retained (this is like Jaw Crusher capacity table above where 48% passes a 1½ in. screen). The 46% of 70 tph gives the 32 tph fed to the secondary crusher shown in Figure below as a roll crusher.

A twin-roll crusher is selected, like those given in the Roll Crusher capacity Table above, to serve as the reduction crusher. The smallest, 24 x 16 roll crusher shown in the Roll Crusher capacity Table above has enough capacity with a setting of 1 in. but the maximum size feed will be too large, that is, the stage of reduction is not large enough. The maximum size of feed coming from the discharge of the primary crusher with a setting of 2½ is about 3½ in. as may be found in this Table.

Screen Analysis of Product from Jaw Crusher, Percent Passing Screen Opening

|

Product Size (in.) |

Closed Side Setting of Crusher (in.) |

Product Size |

|||||||||

|

3/4 |

1 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 |

(in.) |

|

|

Over 10 |

Over 10 |

||||||||||

|

-10 +9 |

0 | -10 +9 | |||||||||

|

-9 +8 |

0 | 2 | -9 +8 | ||||||||

|

-8 + 7 |

0 | 7 |

-8 +7 |

||||||||

| -7 +6 | 0 | 8 | 10 |

-7 +6 |

|||||||

|

-6 +5 |

0 | 0 | 5 | 12 | 12 | -6 +5 | |||||

| -5 + 4 | 4 | 11 | 13 | 14 | 14 |

-5 +4 |

|||||

| -4 + 3.5 | 0 | 7 | 7 | 9 | 8 | 8 |

-4 + 3.5 |

||||

|

-3.5 +3 |

0 | 7 | 7 | 10 | 11 | 9 | 8 | -3.5 +3 | |||

|

-3 + 2.5 |

0 | 5 | 12 | 13 | 12 | 10 | 10 | 8 |

-3 +2.5 |

||

| -2.5 +2 | 3 | 15 | 16 | 14 | 13 | 11 | 11 | 8 |

-2.5 +2 |

||

|

-2 +1.5 |

0 | 0 | 17 | 17 | 17 | 16 | 14 | 13 | 7 | 6 |

-2 +1.5 |

|

-1.5 +1 |

2 | 19 | 26 | 20 | 19 | 15 | 11 | 10 | 7 | 6 |

-1.5 +0.75 |

|

-0.75 + 0.5 |

20 | 20 | 13 | 11 | 8 | 6 | 5 | 4 | 4 | 3 |

0.75 +0.5 |

|

-0.5 +0.25 |

40 | 25 | 13 | 11 | 7 | 6 | 4 | 4 | 4 | 3 |

-0.5 +0.25 |

|

Under 0.25 |

20 | 16 | 12 | 8 | 7 | 6 | 7 | 6 | 3 | 3 |

Under 0.25 |

|

Setting |

0.75″ | 1″ | 1.5″ | 2″ | 2.5″ | 3″ | 3.5″ | 4″ | 5″ |

6″ |

|

Considering a 30-in. diameter roll crusher the maximum size particle that can be nipped with the roll crusher set at 1 in. according to this Equation is F = 0.085(15) + 1.0 = 2.28 in. <3½ in. feed. It will take larger than a 40-in. diameter roll crusher. A better solution would be to use a larger jaw crusher set at 1½ in., then a roll crusher from the Roll Crusher capacity Table above could be used. If the output of this crushing process should have less material of the +1-in. size, the larger crusher could be operated with a closed circuit. That is, the oversize in the output could be recirculated through the roll crusher without exceeding the rated capacity of the crusher. Then all material leaving that crusher with a 1-in. setting would be of a minus 1-in. size.

Another possible solution to this problem would be to use a gyratory crusher for the primary crushing stage. A gyratory like Telsmith model 1110 could be set at 1½ in. in an open circuit with a capacity for 260 tph. The maximum size of stone in the output is estimated to be approximately 2 1/8 in. Then all the output from the primary crusher could be nipped by a 40 in. diameter twin-roll crusher with a 1-in. setting according to the Roll Crusher capacity Table above. The specifications and manufactured limitations, rather than economy, generally govern the selection of crushers.

To find the required areas of screen, the rate of feed of material as well as gradation of the feed must be known. The 1½-in. screen under the jaw crusher is the top deck—no deck correction factor will be necessary. Therefore, the 1½-in. screen will need to be at least 70/2.7 = 29.9 sq ft in area. It must be at least 36 in. wide for an 18 x 36 jaw crusher. So a 4-ft by 8-ft screen would be acceptable. The 1-in. screen is a second deck for the 38 tph from the jaw crusher, so the deck correction factor is 0.90 and that screen capacity is 2.1 x 0.9 = 1.89 tph/sq ft.

The screen area needed under the jaw crusher is 38/1.89 = 20.1 sq ft. For the 1-in. screen below the roll crusher the capacity has no correction factor and the area needed is 32/2.1 = 15.2 sq ft. To handle the output from a 40 x 24 roll crusher the screen will have to be at least 24 in. wide. Perhaps it will be more effective to use one continuous screen of at least 20.1 + 15.2 = 35.3 sq ft. A 4-ft by 10-ft 1 in. screen should be satisfactory.