I have mentioned the fact that, as the % of voids in the crushing chamber decreases, the production of fines by attrition increases. This is like saying that, as the Crusher Reduction Ratio in any given crusher is increased, the % of fines in the product will increase, even though the discharge setting remains unchanged. Both of these statements are true, but the degree to which the product is affected depends to a much greater extent upon the ratio-of-volume-reduction in the crusher chamber than it does upon the actual degree of reduction performed on the material. For a given ratio-of-reduction, the type of crusher with a flared crushing chamber will usually deliver a cleaner product than any of the older types; conversely, more reduction can be performed in the machine without creating excessive fines.

The facts outlined in the foregoing paragraph have an important bearing on crushing plant design. Commercial crushing plant operators are usually desirous of making as few fines as possible, and this is becoming increasingly important as the demand for small grades of screened material increases. To hold down the amount of dust on screenings in the combined plant product, it is essential that the amount of reduction per crushing stage be held within conservative limits; moreover, it is important that the work in each stage be apportioned with due regard to the characteristics of the crushers comprising these stages.

As an example, suppose that it is required to make a reduction of 7:1 in two stages of crushers, one a standard gyratory and the other a fine-reduction crusher. We know from our examination of the crushing characteristics of these types that, for equal reduction ratios, the volume-reduction-ratio in the standard gyratory is considerably higher than it is in the fine reduction crusher. Therefore, if minimum production of fines is desirable, it is logical that the heavy end of the 7:1 reduction should be handled in the latter machine. Generally, for such a case, the split would be about 3:1 to the standard machine, and 4:1 to the fine reduction crusher.

https://www.911metallurgist.com/why-screening-crusher-feed-is-important

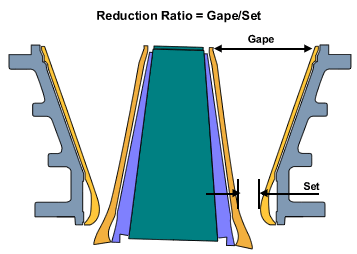

Approximate Crusher Reduction Ratio. F/s*

| Crusher Type | Smaller Models | Larger Models |

| Jaw crusher | 3-20 | 3-10 |

| Gyratory crusher* | 2½—14 | 6—10½ |

| Cone crusher* | 3¼—16 | 5-16 |

| Twin-roll (smooth) | 3½—10 | 2½—8 |

| Hammermill | 1¼—24 | 4—80 |

*For closed circuit operation, open shows lower ratios.