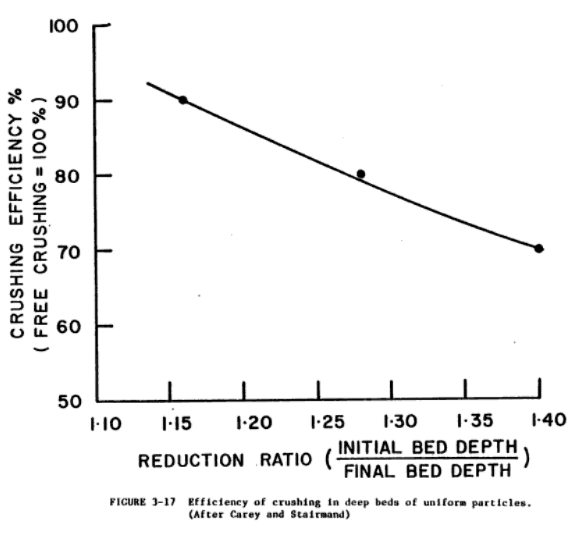

Toward the foregoing goal, engineers investigated the energy efficiency of crushing for less than ideal cases. In the first experiment they studied the effect of factors such as using a deep bed of particles, a situation usually present in a ball mill. The same type of slow crushing experiment described above was performed, but with a bed five or six particles deep instead of a single layer. Single layer particle crushing was taken to be 100% efficient, and measurements were made of the relative efficiencies, i.e., the ratio of the amounts of energy required to achieve the same degree of plate separation in crushing the multi-layer particles to reduction ratios of 1.16, 1.28, and 1.40 (the reduction ratio is defined as the separation of the plates before crushing divided by the separation after crushing).

The results are shown in Figure 3-17. It is seen that for a reduction ratio of 1.32, the relative efficiency of crushing a multi-layer of particles is 72%. Note that crushing ratios in a ball mill are not well defined, but are believed to range up to 1.5 or even 2.0.

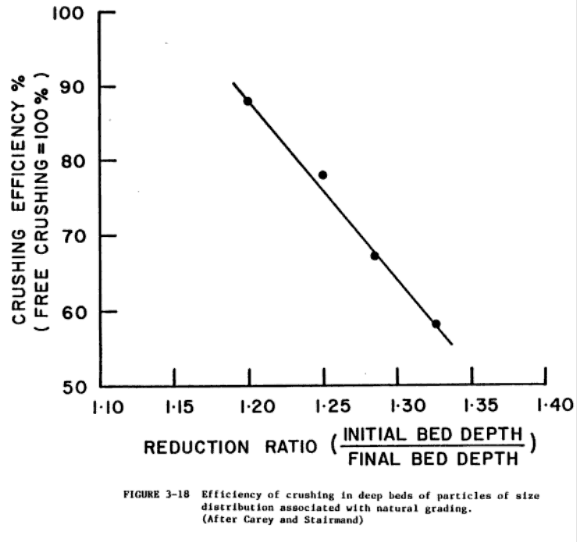

In a second series of measurements, the particle size was not uniform—a distribution of particle sizes corresponding to a natural grading was used.

Figure 3-18 shows the results compared with 100% efficiency for single-layer crushing. It is seen that for the same reduction ratio as above, i.e., 1.32, the efficiency relative to the single layer was 57%.

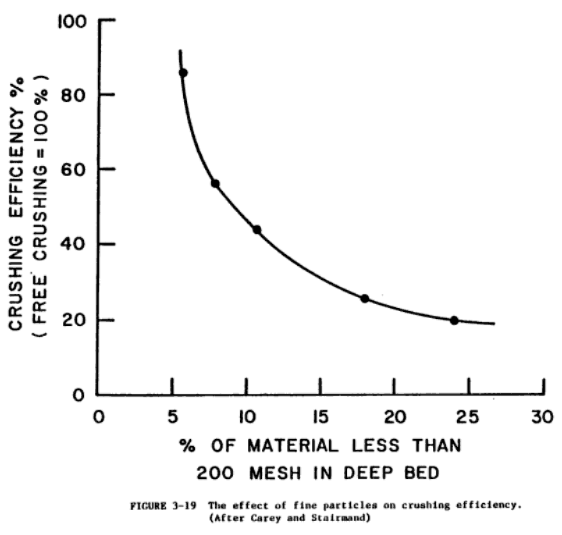

A third experiment was conducted similar to the one that yielded the results in Figure 3-18. In this case, however, the resulting particles were measured to find the percentage smaller than 200 mesh (76 pm), and these were remixed with the bed.

Figure 3-19 shows the reduction of efficiency with the increase of fine particles in the bed. It is seen that the efficiency is rapidly reduced to 20% at a percentage of fine particles believed present even in closed circuit operations that employ classifiers.

The generation of fine particles in quantities of 15% or more takes place in only a few minutes in a ball mill.

According to Figure 3-19 therefore, the efficiency of a ball mill cannot be intrinsically very high even under optimum design with classifiers. However, it is obvious that a crushing device that approaches the free particles condition will have the highest efficiency.

Recently it has been shown, at least for small glass spheres, that crushing energy can be lowered if the sphere is compressed and sheared simultaneously (Schonert, 1979). The sum of the work for compression and shearing is the energy input. At the present state of the art the efficiency can only be compared to that of the associated energy of free crushing. Thus, if a lesser energy is required, a higher efficiency can be calculated over that for simple crushing. As devices are developed for performing this mode of comminution, a minimum associated energy may be developed in the laboratory so that the efficiency of a device can be ascertained.

The same reasoning applies to the other comminution devices, whether they be ultrasonic, pulse heating, or a novel invention. The difficulty is in establishing a comparable model, such as free crushing, when the particle size distribution differs considerably from that obtained by free crushing. Statistical analysis of the energy for each size group can be used, however, and it is expected that reasonable results can be obtained.

Comminution and Energy Consumption By National Research Council (U.S.). Committee on Comminution and Energy Consumption