In the handling of wet, sticky ores such as encountered in tropical areas having distinct dry and rainy seasons, the crushing plant is a section of the mill which must be planned very carefully. Unless this is done, crushing becomes a constant source of trouble resulting in lost production and high milling cost. In some areas rainfall is high for prolonged periods. This seriously affects ore handling and continuity of operations not only in open pit but also underground mining.

Solution to the Wet Ore Processing Problem

A washing section is a “must” in all operations handling wet, sticky ore. This facilitates ore handling, crushing, and also affords a means for separation of primary slimes and increasing grinding capacity. These slimes usually contain the bulk of the soluble salts and in many cases this fraction should be treated separately or even discarded if values are low. Soluble values such as copper sulphate can often be separated from the slime in a thickener and the clear overflow water passed over scrap iron for precipitation of the copper.

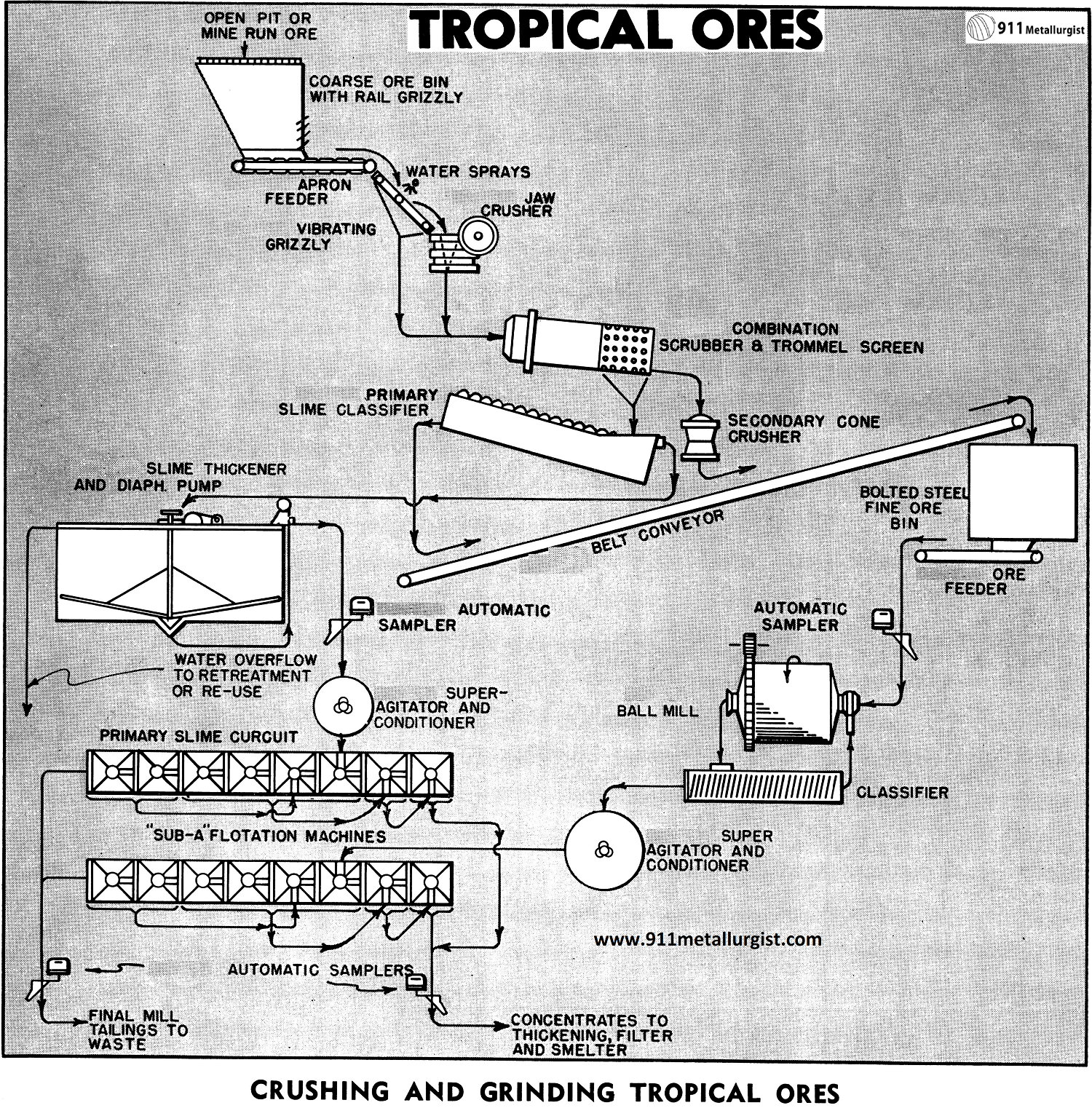

The Wet Ore Processing Flowsheet

In the flowsheet illustrated the basic steps are shown for the average mill. Primary slimes are treated separately, while the washed and crushed ore is ground, classified, and floated in the usual manner. This practice quite often results in better metallurgy with lower reagent cost in addition to greatly simplifying the crushing operation. In most cases it is possible to confine the crushing operation to one or two shifts per day.

CRUSHING AND SCRUBBING

It is highly desirable to use a heavy duty apron feeder under the coarse ore bin to regulate the flow of coarse wet ore. Wearing surfaces and rollers for the apron flights must be designed to stand up under the wet primary slimes without excessive maintenance. Good insurance at this point is to obtain the very best feeder on the market even though the price may be higher than for light duty units.

The ore from the feeder next passes over a roll or vibrating grizzly. For the small 150 to 200 ton per day mill this opening can be 2 inches. This will allow the wet sticky fines to pass through the grizzly. A high pressure water spray over the grizzly often aids in the subsequent jaw crusher operation.

The fines from the grizzly and the crusher discharge pass by gravity and/or conveyor to a Combination Scrubber and Trommel. Here, further scrubbing and washing takes place to separate the ore into two fractions, usually plus and minus ½ inch. The coarse washed fraction is further reduced in a Secondary Cone Crusher without difficulty. Secondary crushing may be in open circuit or closed circuit depending on the physical characteristics of the ore and the degree of size reduction desired.

CLASSIFICATION AND THICKENING OF PRIMARY SLIMES

The minus ½ “fraction from the Combination Scrubber and Trommel is further separated into a sand and slime fraction in a Spiral or Rake Classifier. The slimes plus the water used for sprays in the washing’ and scrubbing operation overflows the classifier and are collected in a Thickener prior to further treatment. This thickening step permits reclamation and possible retreatment of the overflow water, and in addition stores the thickened solids for treatment at a uniform rate by flotation or other means. Crushing, therefore, can be confined to a one shift operation, and the accumulated slimes treated over a 24 hour period.

In the treatment of corrosive low pH ores the scrubber, classifier, and thickener with its diaphragm pump should be of acid proof construction.

The sand product from the Spiral or Rake Classifier discharges on the same belt as the crushed ore and passes on to the fine ore bin. The classifier should be long enough to provide an adequate drainage deck for the sands so a minimum of moisture is entrained in the spiral or rake product. Slimes from conveyor spillage drain to Vertical Sand Pumps. This is an ideal pump for this service since it handles fluctuating feed and can be run with pump bowl dry without damage, or air locks.

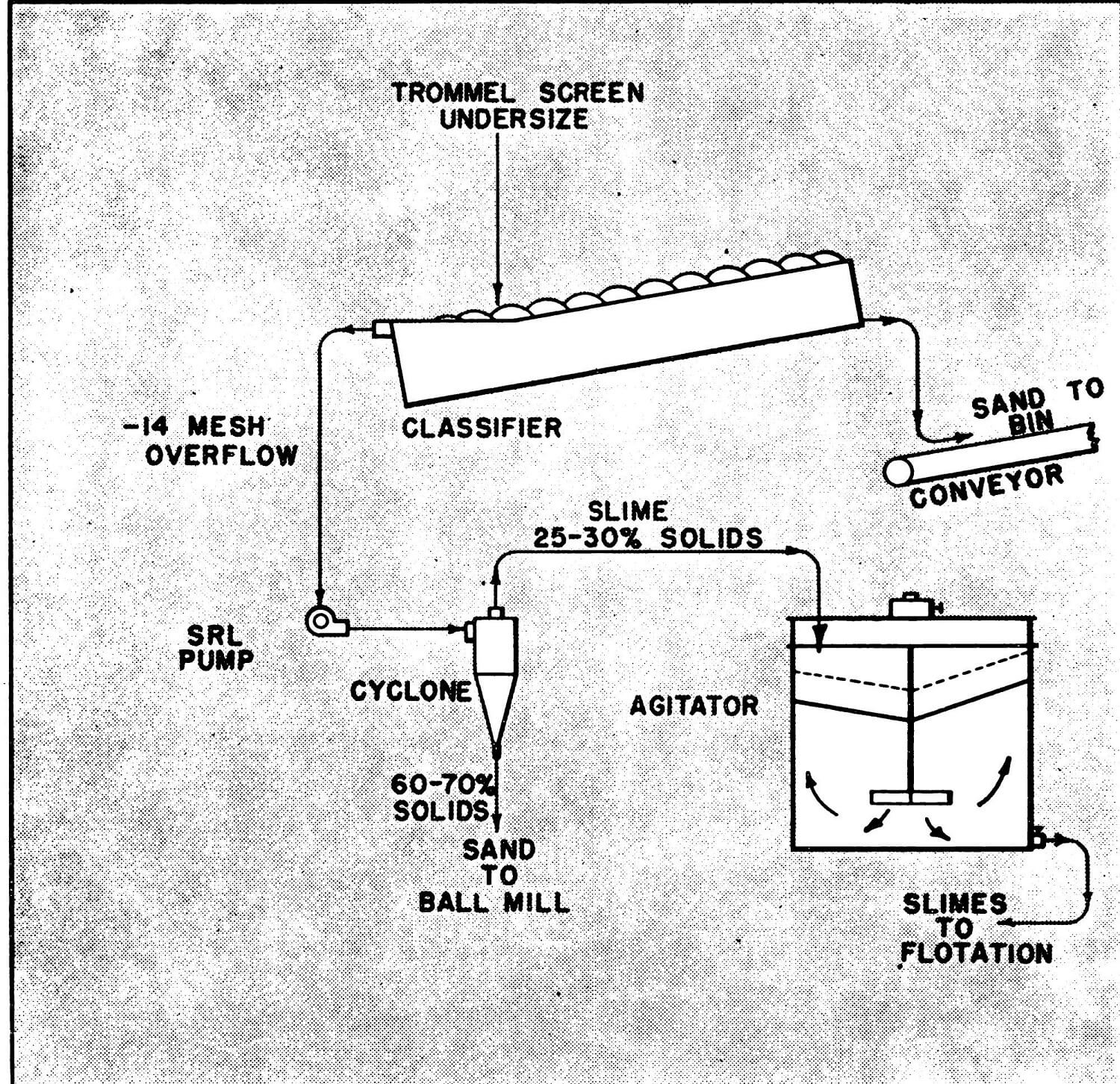

LARGE TONNAGE CRUSHING PLANTS

For plants handling several hundred tons of ore per day the primary grizzly and crusher may be set to produce a minus 4 to 6 inch product. In such cases the Combination Scrubber and Trdmmel must be a heavy duty unit. This is necessary to handle the coarser ore and thoroughly disintegrate any clay balls which would otherwise cause serious trouble in the subsequent secondary crushing steps. It may also be necessary to incorporate vibrating screens into the circuit to improve screening efficiency in removing the fines along with spray and wash water. SRL Pumps and Cyclones for treatment of the primary classifier overflow may also be necessary to make a finer sand-slime split, for example 90% —200 mesh. In some cases it is possible to eliminate the primary slime thickener as illustrated in the circuit as follows:

GRINDING AND CLASSIFICATION

Grinding and classification of the minus ½” washed and crushed ore is accomplished in the usual manner, and generally no problems are encountered. In some cases where this fraction of ore is low in fines it may be necessary to blend back some of the thickened primary slime. This aids in properly lubricating the ball charge and in giving fluidity to the pulp in the classifier for proper size separation.

FLOTATION

Treating the primary slimes in a separate circuit may be highly desirable for a more efficient separation. Often this fraction can be treated at its natural acid pH and the washed, crushed, and ground ore treated in a neutral or alkaline pulp. Alkalinity reagent requirements are kept low under these conditions.