The pump curves published by pump manufacturers are for the performance of the pump on water. Some pump manufacturers use a derating factor to correct the head and efficiency of the pump when pumping slurry.

This a subject which has had a lot of controversy and disagreement It is suggested that the method used be left to the manufacturer The method they use works for them.

As a final check, another factor in the selection of the pump size is the entrance or suction velocity The higher the entrance velocity the higher the wear rate will be on the leading edge of the impeller vanes and the impeller eye. Generally speaking, eye velocities below 15 or 16 ft./sec. are preferred. The velocity must be high enough to insure that the slurry and solids reach the impeller eye, but not so high to cause rapid wear.

Now that we have looked at the parameters which affect the selection and sizing of a pump, let’s take a set of conditions that we have derived by the testing and careful analysis of the system or as supplied by the customer to select a pump:

Flow: 4000 GPM – Mill Discharge Service

Head: 100 ft.

Sp gr of slurry: 1.30

Sp gr solids: 3.0

% solids: 35% by weight

Max. particle size: 3/8″

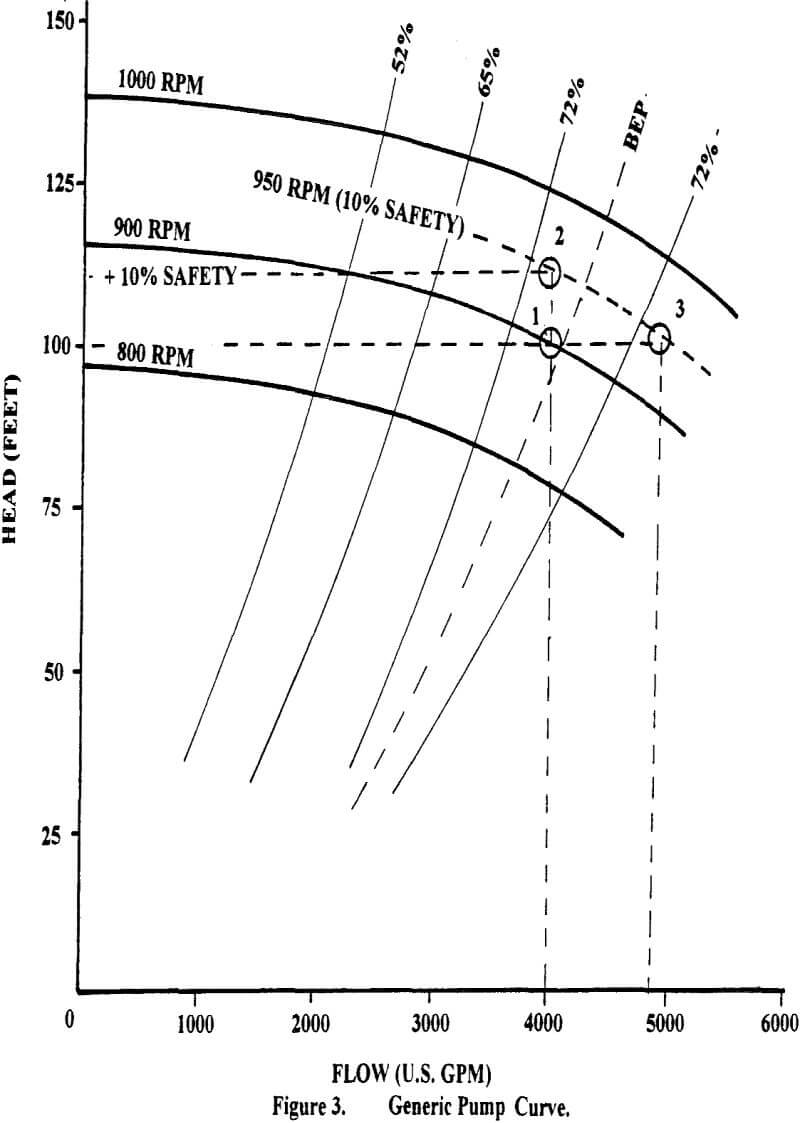

Looking at a generic pump curve for a 12 x 10 x 24 pump (Figure 3), we select the operating point of 4000 GPM at a TDH of 100 ft. This point (Point #1) falls just slightly to the left of the pump BEP and the pump 900 RPM curve. The pump efficiency at the operating point is 72%.

The BHP is (4000) (100) ( 1.30)/3960 x 72 = 182 HP

The pump inlet velocity is 11.4 ft/sec This velocity is low enough to provide good wear life on the suction side.

Let us now look at the effect of adding a 10% safety factor to the head of this pump. The head now becomes 110 ft. and the flow requirement remains at 4000 GPM. This point (Point 2) still falls to the left of BEP, but at a pump speed of 950 RPM. However, the head in fact is only 100 ft. and the pump operating point (Point 3) will move out on the 950 RPM curve to the required 100 ft of head. The result is that we are now pumping a flow of 4900 GPM. At this point we have moved to the right of the BEP and will have accelerated wear.

The break horsepower is now:

(4900) (100 1.30)/3960 x 715 = 225 HP

In this particular example, the problem can be corrected by changing the drive and slowing the pump down.

If the addition of safety factors to the head and flow conditions are such that a larger pump is selected, then the solution to the problem is complicated and costly.