Dewatering Screw Classifiers once had a wide vogue and still are used in some pulp circuits. They were more or less troublesome because solids tended to accumulate on the sloping sides, sloughed off periodically, and plugged the discharge in the apex; the sand discharged was too dilute and contained too much slime; and sand was frequently carried over with the slime. Furthermore, large cones required considerable space and headroom. This classifiers are of the spiral and screw family.

It is of interest that the Homestake, long a user of cones for dewatering and classifying, selected mechanical bowl classifiers for their new mill addition. In the Homestake’s enlarged and rearranged plant are 10 cones of local make, 7 ft. in diameter and with 65-deg. sides. They dewater the pulp from the stamps and feed 10 rod mills which are in closed circuit with an equal number of Clark-Todd amalgamators and Dewatering Screw Classifiers. Cones are used in the Dome plant, Ontario. There are two distributing cones and 16 classifying ones, 4½ ft. deep, with 60-deg. sides and ¾-in. spigot, which tend to build up sulphides in the circuit for selective grinding.

Cones of the Caldecott type, fitted with automatic discharge, are used in four plants at Kolar, India, for dewatering and making tube-mill feed. In this cone the discharge continues to operate until there is a change in the pulp density. If the pulp in the discharge becomes too thin, the plug at the cone bottom closes, allowing the sand to accumulate. The density then increases to the desired point after which automatic control becomes effective.

Dewatering Screw Classifiers in Rand stamp mills consist of a nest of cones 4 ft. in diameter and 5 ft. deep. The overflow passes to secondary cones to be separated into sand and slime. The underflow is divided into as many portions as there are tube mills, each portion gravitating to a dewatering cone 5½ by 7½ ft., the underflow of which is the tube-mill feed. A little water is added to bring the moisture content to 30 per cent. The cone, however, is inefficient, according to T. K. Prentice in Bul., I.M. and M., April, 1935, in dewatering a finely ground pulp for tube milling. It has been found that the Dorr classifier is preferable for this purpose, and this machine is included in the flow sheets of all of the latest plants.

MECHANICAL CLASSIFIERS

The impossibility of preparing clean, leachable sand and sand-free slime from an irregular feed of varying ore by double-cone classification led to the invention of the original Dorr classifier at the Lundberg, Dorr, and Wilson mill at Terry, S.D., in 1904.

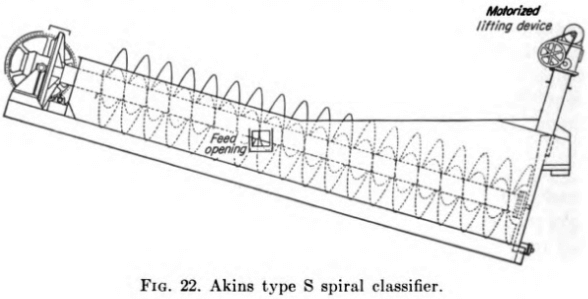

Mechanical screw dewaterers had been used before this time, including Johnson’s shovel wheel, Scobey’s belt dewaterer, and other devices, such as George Moore’s cylinder with spiral conveyor. The Akins ribbon screw followed about 1910, and Philip Argall’s double solid spiral, the Avoca, a few years later. The Scobey belt was developed at the Esperanza and used especially in Mexico, and later a cylinder with spirals introduced by Hardinge, while on the Rand a spiral draining sand from a cone has met some favor.