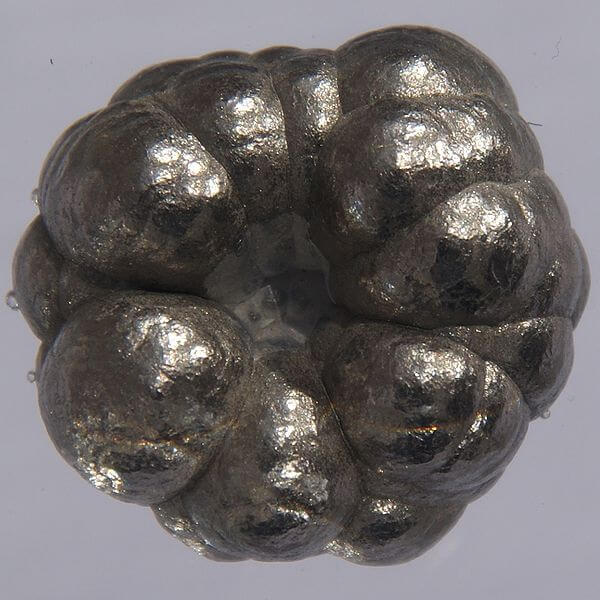

Nickel ore might be abundant these days, but that wasn’t the case in the past and, like most things, this excess will be over in a near future.

Nickel ore might be abundant these days, but that wasn’t the case in the past and, like most things, this excess will be over in a near future.

According to a British Geological Survey, referred by the site Metal Miner, 73 percent of the continental world nickel resources are lateritic. Still, the current dominant extraction process, called High Pressure Acid Leach (HPAL), is technologically challenging and very expensive.

However, there’s a new nickel extraction technology that claims to cut production costs in half, opening the door to the exploration of ore sources previously considered unprofitable.

This new process, developed by the Australian company Direct Nickel (DNi) with CSIRO‘s help, uses hydrochloric acid instead of sulphuric acid and has reached great results in tests prior to commercial investment.

Taking just between two and four hours for leaching, this new process is way faster than HPAL. Besides, the resulting waste is much less in volume. This method allows the same process circuit to treat different kinds of laterite ores, as well as recycle the nitric acid and reduce costs.