A sectional view of the Dodge jaw crusher here below. The mechanism of this machine is so simple that it is hardly necessary to enlarge upon what can be gained from an examination of the cut.

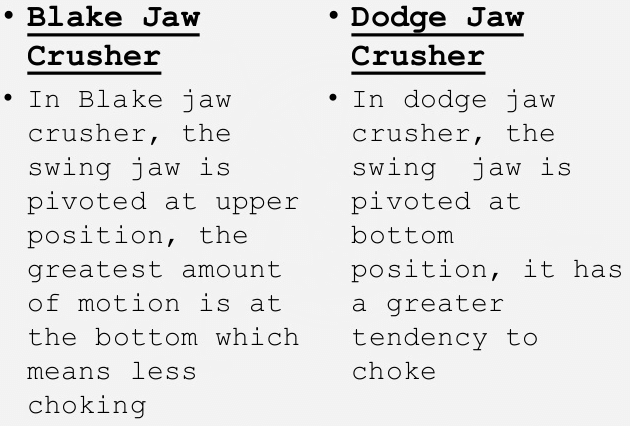

In one respect, the Dodge machine is a reversal of the actions we have been discussing; its movable jaw, being pivoted at a point below the discharge opening, has minimum movement at that opening, and maximum movement at the receiving opening. Because the choke-point and the point of least motion coincide in this crusher, it is to be expected that it would be lacking in capacity, as compared to similar sizes of the Blake-type crusher. The Dodge machine has the virtues of simplicity, low cost, and ease of adjustment and maintenance, but, due to its low capacity, its field is restricted to rather narrow limits.

By reason of the small movement at the discharge opening, the natural expectation would be that the Dodge crusher would deliver a very uniform product, but this would hold true for only a very limited feed rate. The rapid action at the top of the crushing chamber tends to crowd material into the lower zone; this, as we have seen, tends to promote a packed condition, with accompanying production of fines by attrition. The machine works well on hard, clean-breaking rock, or ore, but does not have characteristics suitable to the handling of soft, friable materials which incline to cling and pack.

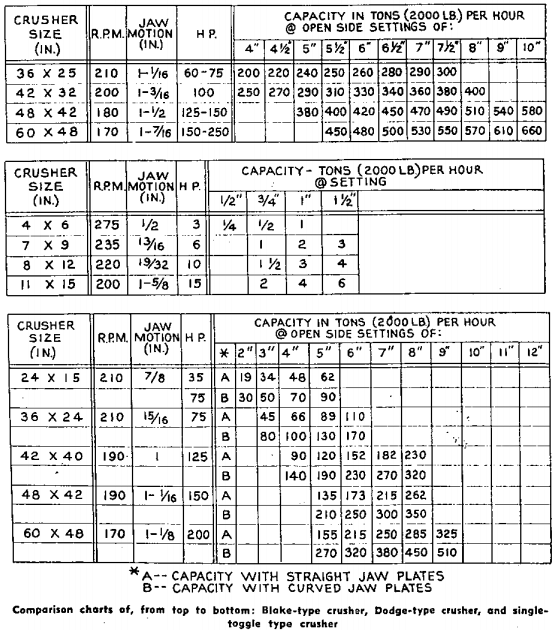

The Dodge crusher fits into a number of low-capacity applications, such as small mining operations, sampling plants, laboratory work, and numerous special applications where a small product is required, but where the tonnage involved does not justify a two-stage operation. The machine is capable of making a very large ratio-of- reduction, which is an important feature for the types of application outlined. A table of ratings of Dodge crushers is given.

The Dodge-Jaw Crusher : In the Dodge Crusher, the moving jaw is pivoted at the bottom. The minimum movement is thus at the bottom and a more uniform product is obtained. However this type of crusher is not commonly used due to its tendency to choke. The larger opening at the top enables it to take very large feed and to effect a large size reduction. This crusher is usually made in smaller sizes than the Blake-Jaw Crusher due to high fluctuating stresses that are produced in the members of the machine.

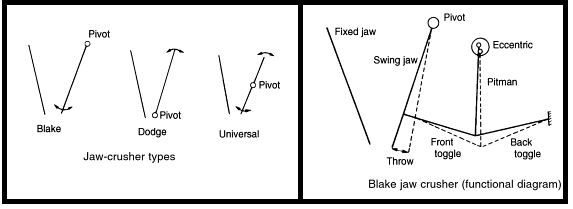

Jaw crushers occupy a very important position in the field of mineral processing. Their simplicity of operation and repair, combined with their ruggedness, enable them to be widely used as primary crushers. The three general forms of the jaw crusher are: Blake. Dodge and Universal. These are distinguished by the manner in which the movable jaw is moved in relation to the stationary jaw. In the Blake-type crusher, which is the most common type of jaw crusher, the movable jaw is pivoted at the top so that it has a fixed receiving area and a variable discharge opening. The greatest amount of motion is at the bottom of the V. which implies that there is little tendency for a crusher of this kind to “choke” by which it is meant that it becomes filled with partially crushed material that will not drop out the discharge).

These crushers produce fewer fines than Dodge crushers, and can handle stickier materials; they are also made in much larger sizes than Dodge crushers. In the Dodge-type crusher, the movable jaw is pivoted at the bottom of the V. and thus it has a variable feed and a fixed discharge opening. This design also implies that the greatest amount of motion is at the top of the jaws. This type of crusher yields little oversize product and a great many fines. It also tends to “choke”. On this account, these crushes operate only on moderate amounts of dry. free-flowing solid materials. In the Universal-type crusher, the movable jaw is pivoted at an intermediate position, with the result that it has variable discharge and receiving areas. Apart from jaw crushers, gyratory crushers also occupy an important position in the list of primary crushers.

https://www.slideshare.net/funkygenesis/jaw-crusher-42547675