The first thing that probably comes to mind when most people think of searching for gold is panning for gold from streams. After that, they would most likely name mining gold from solid rock, such as from a large open pit or from tunnels blasted along lode-bearing quartz veins. Who could blame them? Exciting stories of gold prospectors discovering the first bright flash in the pan abound, as do those of miners searching through the darkness and finding a streak of gold by firelight, and who isn’t impressed by the visual splendor of a giant open pit that dwarfs the most monstrous of trucks? As exciting as these methods are, they’ve unfortunately drawn attention away from one of the most versatile and environmentally friendly methods of extracting gold; the dredge. This method was first used a little over a hundred years ago, is quite efficient, and may be used in a variety of situations.

Dredging is similar to panning for gold in that prospectors sift through sediment in an attempt to collect pieces of gold that have been displaced from the original solid rock in which they were deposited. The gold may have been displaced by mining operations or by natural processes such as weathering due to the action of water. Whereas panning is helpful for identifying if gold is present, dredging is used to extract as much gold as possible from the location, and is like a very large scale pan. Both methods utilize the density of gold, which cause it to collect at the bottom of the pan (for panning) or sluice box (for dredging).

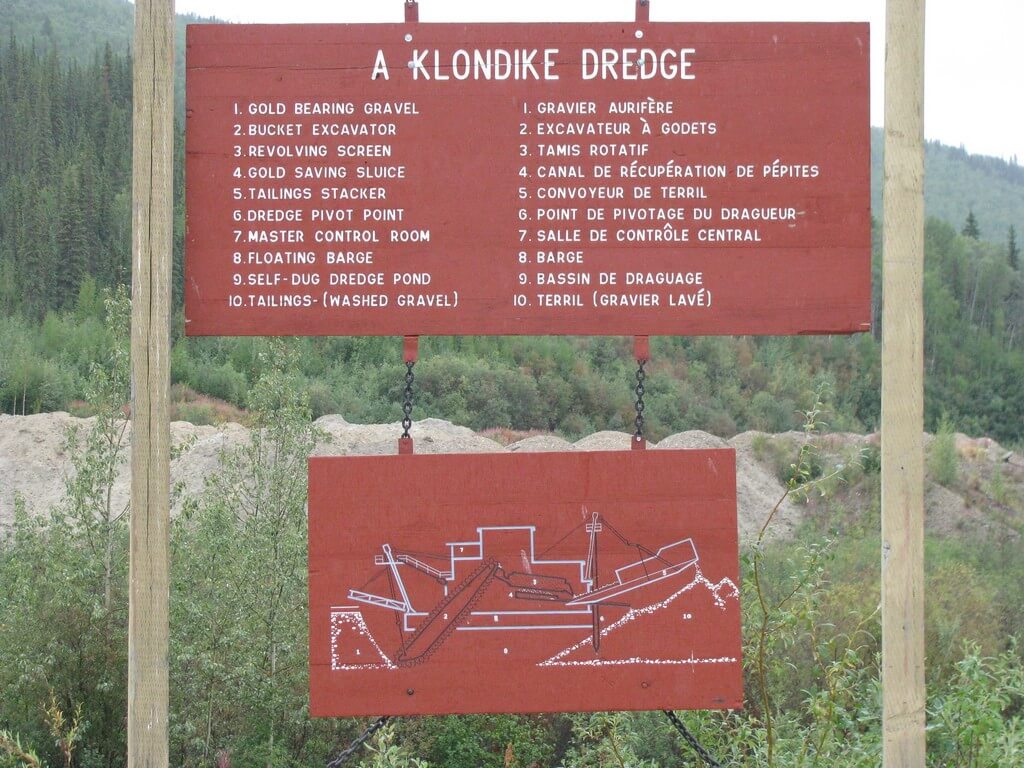

The photo above captures a diagram of an old gold dredge which has been posted in front of one of its tailings piles (a tailings pile is the pile of gravel that is left after the gold has been extracted), and is helpful in explaining even how modern gold dredges work. The diagram shows the components of the dredge, which included a conveyer belt of buckets (the bucket excavator) to scoop up the gold-bearing sediment from the bottom of the pond, a revolving screen (which was rinsed with water at a constant rate and allowed the dense gold to separate from the gravel), and the gold saving sluice. Instead of buckets, modern dredges use suction hoses that vary in length between about two and ten inches in diameter. The smallest modern dredges are portable, affordable, and may be operated by one person.

Several things to remember when prospecting with dredges are to check state regulations on dredging, to follow safety guidelines carefully (most require at least two persons to operate safely), and to read the instruction manual carefully because they can be touchy machines. Although it’s unlikely that modern dredges will produce the nine tons of gold that the pictured dredge did, a carefully placed and operated gold dredge may be profitable.