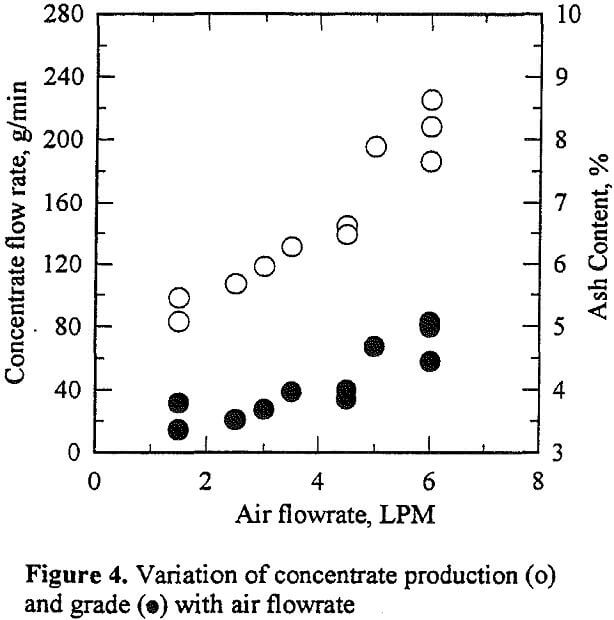

On a flotation column cell, the variation of concentrate flowrate, clean coal yield and product grade with air flow rate are shown in Figure 4. These tests were carried out using a 5 wt. % feed slurry. The results show that the concentrate flow rate, yield and product ash content increased with air flow rate. This trend is expected since the available bubble surface area increases with air flow rate. For solid feed rate in the range 240-320 g/min, it appears that conditions of free flotation are encountered at air flowrates above 3 LPM. This is consistent with our earlier observation on the presence of air bubbles in the tailing samples collected at low air flowrates. Since the project objective called for the production of clean coal with an ash content of 5%, our results suggest that a single column flotation stage is sufficient for the beneficiation of the Lower Kittaning seam coal at yields of 66-80%.

Evaluation of Vortactor Turbulent Contactor

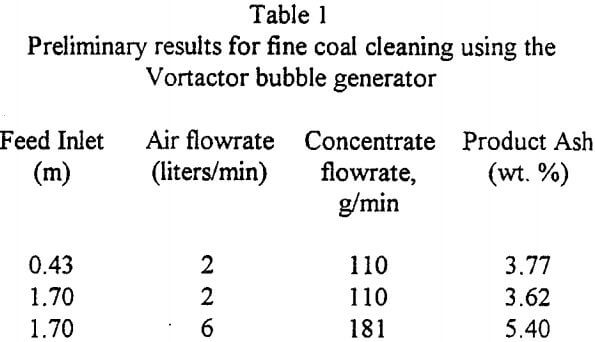

The Mott porous sparger used in the studies reported above was replaced with the Vortactor. Table 1 shows the preliminary results obtained with the Vortactor bubble generator. The preliminary results at an air flowrate of 2 LPM show that the concentrate flowrate and product grade was independent of feed location. This observation is consistent with the results obtained with the Mott sparger. In these experiments, there is no bulk transport of feed material above the inlet point. Thus, the results suggest that particle-bubble attachment is rather fast and takes place in the contact chamber and/or feed line.

Increasing the air flow rate from 2 liters/min to 6 liters/min increased the concentrate flowrate. As the results with the Mott static sparger show, this increase in concentrate flowrate was at the expense of an increase in the product ash content. The reasons for the higher ash content observed with the Vortactor bubble generator at an air flowrate of 6 LPM are not entirely clear at the present time. However, our gas hold-up data suggests that the column operating conditions did not favor adequate drainage of the froth. This observation suggests that the gas hold-up in the froth zone may be an important operational variable in column flotation studies.