The methods of sampling and ore reserve estimating used can fall into two divisions because of the difference in occurrence, manner of prospecting, and methods of mining: that for the underground operations and that for a shovel operations.

The orebodies may be divided into three classes: Replacements of limestone, replacements of porphyry, and replacements of contact breccia. The first class is more or less intimately related to porphyry intrusions, although in badly fractured country this relationship may not be well shown. These orebodies are mainly oxide and carbonate ore and very irregular, both in size and outline, although usually roughly lenticular and following the bedding of the limestones. There is usually quite a sharp boundary between the ore and waste in the carbonate and oxide orebodies and sampling is not necessary to determine the limits of commercial ore. In the sulfide orebodies it is exceedingly difficult, without sampling, to determine the boundary between commercial ore and the surrounding low-grade or barren pyrite. Calculations made a few years ago showed that these orebodies had an average thickness of 35 ft. As some of the orebodies have a thickness of from 100 to 300 ft., it can be seen that the smaller ones form a difficult problem both in prospecting and in estimating.

SAMPLING NECESSARY TO DETERMINE BOUNDARY

In the replacements in porphyry, both underground and in Sacramento Hill, the boundary usually cannot be determined without sampling. There is a gradual decrease in metal-content until barren material is reached; this gradation may occur within a short distance or may extend for several yards.

Surrounding the Sacramento Hill porphyry stock is a wide zone of contact breccia composed of fragments of porphyry and limestone, all intensely silicified. Within this mass have been found many replacements of sulfide, some barren and some carrying enough copper to constitute ore. These deposits are extremely irregular; as to location, size and copper content, and offer some of the most difficult problems of prospecting. No set of conditions especially favorable to their formation has been recognized, and without sampling it is impossible to determine whether a certain mass of sulfide will be commercial ore or not.

SAMPLING METHODS FOR UNDERGROUND OPERATIONS

Different kinds of samples are taken in the mines, depending on the reason for which the information is desired:

Grab samples, taken by the shift boss or foreman, are used as a guide in mining operations.

Chute samples, taken from the cars as loaded by carmen under shift-boss orders, are used to determine the grade of ore mined in a certain section for the shift or day. Once a month, a complete analysis is made of a composite of the daily chute samples from each stope. This analysis is used in figuring minimum grades for mining in each section of the mine.

Belt or shipment samples are taken by the sampling department from the loading belt at the main hoisting shaft and from the mine cars, when dumped, for the ore that is not hoisted. These samples give production figures for the day and 15-day period, and are checked against the samples taken at the smelter. These samples, adjusted to conform to those from the smelter, form the base on which calculations are made to show the actual grade mined in each stope for the 15-day period. As separate belt samples are taken for each loading pocket at the shaft and a record is kept of the ore passing through each one, an accurate adjustment is possible between the, belt samples and those taken at the chutes.

Channel or groove samples, taken by the sampling department, are used for records of ore passed through in development work and for estimating grade of ore developed before stoping commences. Channel samples are taken in the stopes when difficulty is experienced in determining points at which material below the minimum grade desired is being mined. These samples are taken with a pick, hammer, and moil, or a light air hammer fitted with a moil point. Channels average about 1 by 4 in. and, in uniform ground, are taken for 5-ft. intervals. Where there is an abrupt change from ore to waste, or especially rich seams are found, the sample is divided and the length of sample in each material is noted. In locating channel samples, the common precautions in regard to direction of sample with relation to structure and of cleaning the surface of oxidation products are observed.

In the oxide and carbonate orebodies, little channel sampling is done, as the change from ore to waste usually is easily recognized by an experienced man. In these orebodies, the chute samples give the information desired. In the sulfide orebodies, however, channeling is essential to determine the boundaries of “pay ore.” Most of these orebodies are channeled before stoping commences and as necessity arises during the extraction period.

Assay maps show all channel samples and a comparison of chute and belt samples and mine and smelter samples made up for each 15-day period. The average difference between the chute and belt samples is about 0.4 per cent, and between the shipment samples taken at the mine and smelter, about 0.2 per cent., on a copper content of about 7 per cent.

ORE-ESTIMATING METHODS FOR UNDERGROUND OPERATIONS

Prior to 1913, estimates of two classes of ore were prepared by the engineering department : ore in sight and probable ore. The first class was calculated by extending known faces of ore 10 ft. into the solid. The estimates of the second class of ore were based mainly on the judgment of the man making the estimate. Grades were given in round figures and again represented the opinion of the estimator. In 1913, the ore estimation was transferred to the geological department, where the present reserves are calculated. Semiannual estimates are prepared on Jan. 1 and July 1, but estimates of various orebodies or areas are made when desired by the management.

For the calculation of ore reserves, the detail figuring is done in bound books 10 by 12 in., the completed calculations are transferred to cards 5 by 8 in., one card being used for each orebody. Summary cards, one for each division of the mine, are also made up, as well as general summary cards for the entire mine. The latter show not only the tonnage remaining in the mine but also the change since the previous estimate and previous year, the footage of development work, tonnage mined, total tonnage developed and tons mined and developed per foot of development work done.

The general principle underlying the calculation of ore reserves is a critical study of the individual orebody under consideration, its history, present condition, and geological relationship. The methods used for estimating the reserves in the limestone orebodies is determined by intimate knowledge of the orebody; Sacramento Hill porphyry deposit is estimated separately and by a different method. The methods are:

- From horizontal sections, where the total volume of the orebody is calculated, the tonnage mined is deducted to secure the reserve.

- From horizontal sections where only the ore remaining is estimated.

- From vertical sections where the total volume is calculated and the tonnage mined deducted.

- From drifts and raises that cut ore in which no other work has been done.

- From the sill floor of a stope with no work done below it.

- From stoping operations of other companies on the property line, but with no work done opposite them.

- Where orebodies are following the same porphyry dike or fractures.

In the construction of sections for estimating, all available information from drifts, raises, winzes and intermediate work is used. Not only is account taken of sampling results but geological features and their relationship to the ore are considered.

The first method above is used where the orebody is fairly regular and where the tonnage mined can be obtained easily. The second method forms an important part of the estimating practice as a large number of orebodies are calculated by it at present. In this method, the area of ore remaining at an elevation is taken for a height corresponding to the floor of the stope at which it occurs; for example, sill floor 10 ft. and stope floor 8 feet.

In the third method, where possible, vertical sections are spaced at intervals, up to 50 ft., depending on the location of raises. Areas of ore are not connected between levels unless raises have gone through practically on the section. To obtain the reserve, the tonnage mined is deducted from the total volume of the orebody. This method is the most desirable, on account of irregularities in vertical extent of the ore- bodies and is used whenever the necessary information is available.

Where ore is encountered in drifts or raises, it is figured as extending for 10 ft. beyond all free faces, unless known to end within that distance. In the past this has meant a block 28 by 25 ft. for drifts, taking the length of ore in the drift for the third dimension, and 25 by 30 ft. for raises, for the distance the raise was in ore. Where a sill floor of a stope has no work below, the sill area is projected downwards 10 ft. Where ore is mined by the other companies up to the property line and no work has been done opposite, the area on the line is projected 20 ft. into Copper Queen ground.

In a few places, orebodies that are following the same porphyry dike or fracture are connected for distances not exceeding 100 ft. This method was used much more in the past than at present.

The weight of the ore is taken from actual weights of broken ore, determined at intervals by the engineering department and applying an expansion factor of 1.6 to 1. By averaging the weights obtained since estimating by the geological department started, 9 years ago, an accurate figure has been secured, which is not changed according to individual weighing of ore. This weight factor varies from 0.057 to 0.110 and is applied to the estimated volume to reduce it to tonnage figures.

Ore grades are figured on past production of each orebody. For this purpose the original estimate made by the geological department was given a grade based on an average of all chute samples taken. In later estimates, this figure has been corrected by averaging with it the grade mined in the six months preceding the estimate. By disregarding the tonnages represented in the two figures averaged, it is assumed that the ore remaining will be more nearly of the grade just previously mined than that of preceding- periods. In using this method for ore reserves, the economic aspect of the operations of the previous period must be considered. In other words, it is necessary to consider whether especially rich portions of the orebody have been mined, or whether the grade obtained can be assumed to be more or less that of the entire deposit. In one section of the mine, the grade of the orebody is calculated from channel samples alone. This is an extension of the disseminated ore of Sacramento Hill that will not be included in the steam-shovel operations.

The tonnage in this orebody is calculated from vertical sections and the grade arrived at by taking a careful geometrical average of the samples on each section. Two sets of sections, at right angles to each other, are used and the results obtained from the two estimates averaged for the final figures. Few samples used with one set of sections appear in the estimate from the other set, but the results have been found to be remarkably close both as to tonnage and grade.

SUMMARY OF UNDERGROUND METHODS

To summarize briefly, experience has shown that, for orebodies of the type of those in the district, the following points apply:

- Systematic sampling of oxide and carbonate orebodies is not essential.

- Massive sulfide deposits must be carefully sampled to determine the boundary between ore and waste.

- Careful and detailed sampling of disseminated ore-bodies is a necessity.

- Vertical sections are the most accurate means of estimating.

- All available geological information must be used to secure accurate figures on reserves.

- Only about three years supply of ore, in limestone replacement deposits, is developed ahead of stoping on account of the difficulty and expense of maintaining openings in them and loss of interest on money involved.

- Ore estimates are of value to show the comparative condition of the mine rather than its probable life.

Preliminary to the systematic development with churn drills, an accurate contour map of the region, on a 50-ft. scale with a contour interval of 5 ft. was made. This map was laid out in 100-ft. squares. Drilling was started as nearly on the corners of these squares as the nature of the ground permitted.

During the process of drilling, water was poured into the hole to form a sludge with the cuttings. Material samples were taken at intervals of 5 ft., all of the cuttings from the 5 ft. going to make up the sample, whether the sludge was bailed out more than once or not while the distance was being drilled.

SAMPLING AND ESTIMATING

Among the errors peculiar to this method of sampling are: The tendency of the hole to cave; the concentration of heavy minerals in the bottom of the hole; and the deflection of the hole from the vertical. The first of these was largely remedied by casing the hole when it was found necessary. The error arising from the concentration of heavy mineral in the bottom of the hole was negligible, because the cuttings were so thoroughly mixed by the drilling tools that the heavier particles had practically no time to settle out before the sludge was removed by the bailer. Also, at the taking of each sample the hole was cleaned as thoroughly as possible. As nearly as has been determined, there has been little difficulty because of holes deflecting from the vertical; several holes were checked where they penetrated underground workings and the deflection was very small, considering the depths of the holes drilled. As several of the drill holes pierced underground workings, it has been possible to check the accuracy of the churn-drill method of sampling by driving raises along the holes. The general results obtained from these raises agree closely with those obtained from the drill holes.

ESTIMATING ORE RESERVES

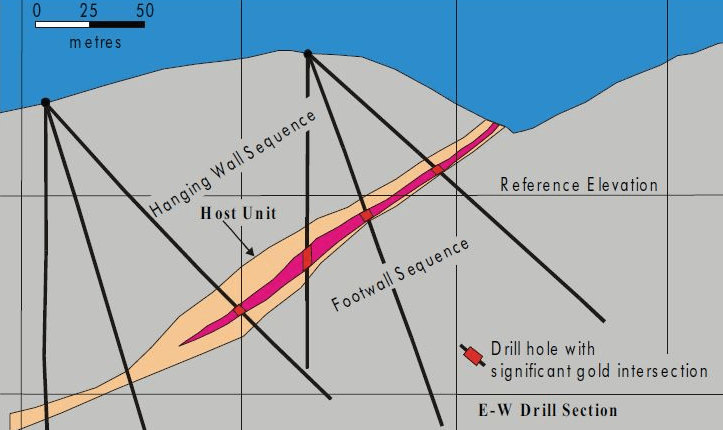

From the information furnished by the assay office and the sampler at the drill, a log of each hole was made, which showed the location and value of each sample in depth. The ore in each hole was grouped into classes according to grades, as follows: Samples that assayed better than 3½ per cent, copper, “S” ore; from 1¾ to 3½, per cent., “E” ore; from 1.3 to 1.75 per cent., “C” ore; from 1 to 1.3 per cent., “F” ore; from 0.8 to 1.0 per cent., “L” ore; from 0.5 to 0.08 per cent., “P” ore. With these logs as a guide, cross-sections of the orebody were made both ways through the orebody at intervals of 100 ft. along the sides of the squares before mentioned. If a hole did not come exactly on the section, but was several feet away, the information contained in the hole was projected to the section and recorded there, the distance and direction of the hole being noted. These cross-section sheets were used to show the general form of the body, and the relation of the different classes of ore to each other and to waste intrusion. They were not considered accurate enough for use in making the final estimates of ore tonnages. These estimates were made by the triangular-prism method, as follows:

Using the cross-section sheets, together with the logs of the holes as a guide, a triangular plat on a 50-ft. scale was made, the apexes of each triangle being a churn-drill hole. Considerable care was necessary in making these divisions, so that each triangular prism would be of equal value. This divided the whole orebody into a series of triangular prisms, the edge of each prism being marked by a churn-drill hole. From the log of each drill hole, the ore reserves were calculated.

The number of feet of each class of ore is multiplied by its assay value, which gives the feet per cent, of each class of ore. The total footage of each class of ore divided by its feet per cent, gives the average content of that class of ore in the hole. Three of these holes form the edges of a triangular prism. Each triangular prism is given a number and its volume and grade are calculated separately. The results from each triangular prism are tabulated and give the total volume of each class of ore together with its assay value.

In converting the volume into tons, it was found, after determining the specific gravity of the ore, that for “S,” “E,” “G,” and “F” classes of ore, 12 cu. ft. equaled 1 ton, and for “L,” “P,” and “waste,” 13 cu. ft. equaled 1 ton, These factors were used in determining the tonnage of each class of ore and also the total tonnage.

Summarizing the above; holes were drilled through the orebody at the intersections of 100-ft. squares and these holes sampled at 5-ft. intervals. Logs of the holes were made showing ore by grades and classes. The orebody was divided into a series of triangular prisms, the edges of each prism being churn-drill holes. The average value of each prism was calculated separately and the results summed up for total ore in the orebody.

Electrical Precipitation of Solids from Smelter Gases

The fundamental principles of the process in its simplest form are set forth. It is shown why the Cottrell process during recent years has in a large measure supplanted the bag-house and dust chamber in treating smelter gases.

The commonly accepted theory concerning the manner in which the dust particles are charged and precipitated is given. It is pointed out that the thing most important to the operating man is how the particles may be enabled to give up their charge to the electrodes under all conditions, rather than the manner in which they receive it.

The various types of treaters in common use are described and discussed. The advantages of straight line treaters over those in which the gases are by-passed are emphasized.

It is shown that the gas is ionized much more efficiently for a given power consumption and the construction simplified and reduced by arranging the electrodes in the flue so that their electric fields are in series with each other. It is shown that this is accomplished by causing the gas to flow parallel to the electrostatic lines instead of at right angles to them, as in all other types.

The factors of lead and copper metallurgy are given which control the amount of sulfuric acid and water vapor in the gases. It is also, pointed out that these things are a measure of the successful operation when treating smelter gases.

The physical rather than the chemical structure of the dust in suspension is shown to be the all-important matter. Several theories are given as to why flue dust is so much easier to precipitate than fume. A number of photomicrographs are given to illustrate the difference in physical structure between fume and dust.

Two methods are featured of obtaining sufficient conductivity in a dry precipitated coating to permit the electric charge to leak through it to the electrode. The theory of selective absorption is advanced as an explanation of how aqueous vapor added to the gas stream functions in this respect. The method of adding very finely atomized sulfuric acid is shown to be the most practical, because it does not have certain disadvantages of the water and its higher boiling point permits a wider field of application. Its action is shown to be due to the fine acid particles being precipitated with the dust particles, thereby imparting conductive film to the particles by diffusion.

The amount of free sulfuric acid in grams per 1000 cu. ft. of gas which permits a good precipitation on gas without conditioning is given from tests made on a large installation.

The theory of back ionization and phenomena of discontinuous dielectric are discussed. Electrical matters are shown to be secondary to treater design and to the conditioning gas. All that can be expected of electrical equipment is to stress the space between electrodes to the economical limit. Local conditions must govern choice of electrical equipment.

The tendency to regard electrical phenomena, such as surging, which as a rule accompanies poor precipitation, as causes rather than effects, is cited. Effects of conditioning gas in reducing surges is shown.

Internal reactance in transformer best suited to precipitation work is discussed, also possibility of exceeding the practical limit and wasting power on treatable gas by carrying voltage up to the point of disruption; necessity of knowing electrical values in the treater, and these are best obtained with milliammeter and electrostatic voltmeter; finally, the subject of proportioning the plant investment between electrical equipment and treater is covered.