How much you feed a thickener and how/where you feed it will determine how well slurry or concentrate settles it it as well as the level of ease or difficulty you will have at obtaining a good underflow density and overflow clarity.

How much you feed a thickener and how/where you feed it will determine how well slurry or concentrate settles it it as well as the level of ease or difficulty you will have at obtaining a good underflow density and overflow clarity.

By using the head assay of the concentrator, and the metallurgical test results that determined the percentage of recovery and the density of the thickener feed to be expected, it is easy to determine the volume that will be going through the thickener. Unfortunately that isn’t the only information that is required. You also have.to know how long it will take the concentrate to settle.

To determine this bit of knowledge the first thing to do is pour a sample of concentrate that is at the expected density into a graduated cylinder. Let the cylinder stand for a set period of time. Once the time has passed you will be able to measure, through the clear glass of the flask, the amount that the slurry has settled. From this simple test you will be able to determine the SETTLING RATE of the concentrate.

After you have the settling rate you will know how long any one piece of mineral will have to be in the thickener before it settles to the bottom. That, plus knowing the volume of the tonnage that will be processed during that time will indicate the necessary capacity of the thickener. Learn thickening basics.

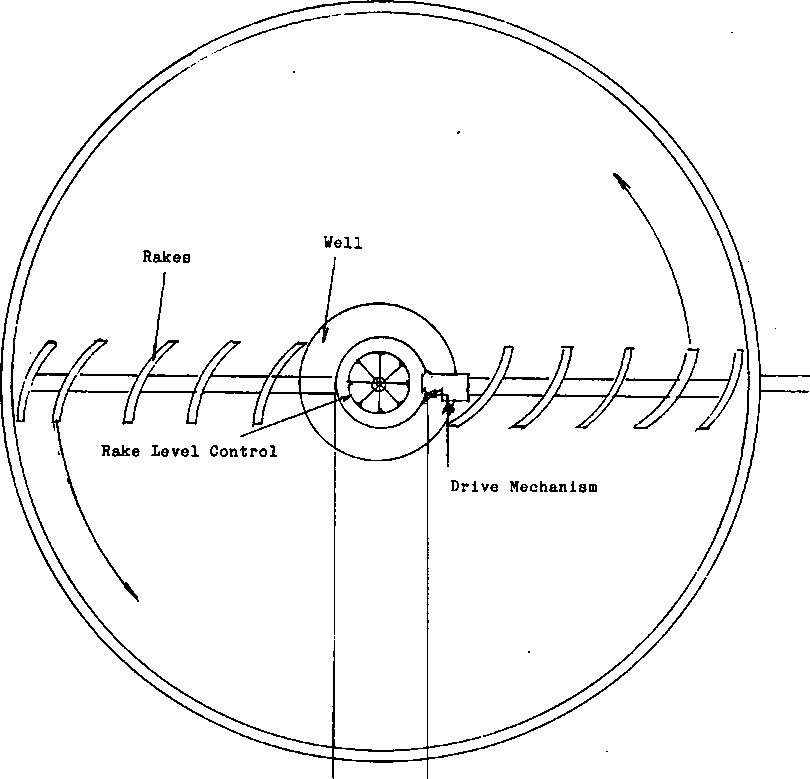

The operation of the RAKES on the bottom require that the settling mineral be distributed evenly over the entire BED. (This is the portion of the thickener that the rakes are pulled over.) The bed is similar to a rock box in the fact that it is there to protect the bottom from wear.-It is a permanent part of the thickener, and often no more than a layer of settled concentrate.

The operation of the RAKES on the bottom require that the settling mineral be distributed evenly over the entire BED. (This is the portion of the thickener that the rakes are pulled over.) The bed is similar to a rock box in the fact that it is there to protect the bottom from wear.-It is a permanent part of the thickener, and often no more than a layer of settled concentrate.

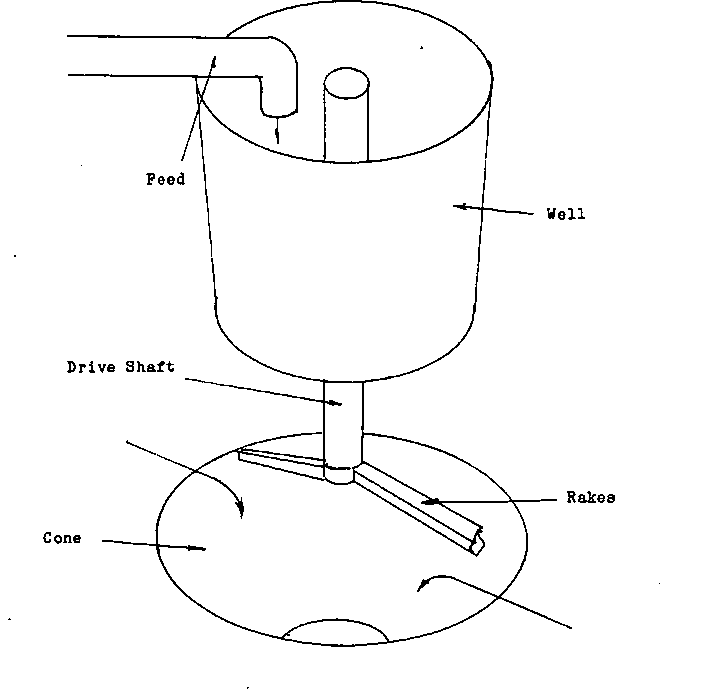

To achieve the required even settling, the final concentrate must be introduced at the centre of the thickener. The area that it is discharged into is called the WELL of the thickener. This is circular piece of metal open at both ends.

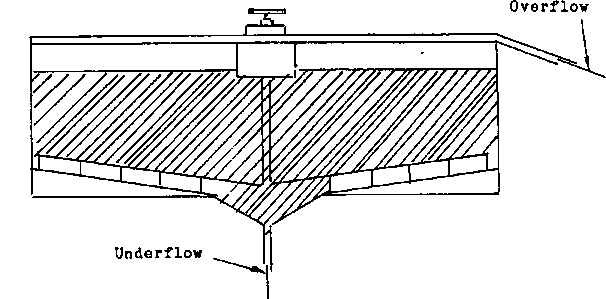

While the water is called either the LIQUEUR or the OVERFLOW. When the slurry is introduced to the thickener, the movement of the rakes as they are turned by the central shaft ensures that the mineral is settling uniformly.

When I first began talking about the components of the thickener I mentioned that the WELL of the thickener is the place that the feed enters at. As I mentioned, this is to aid in evenly spreading the concentrate over the bed of the thickener. It also does one other thing, there is always a portion of the mineral that settles faster than the rest. It allows this material to settle straight into the cone of the thickener to be taken away as fast as possible.