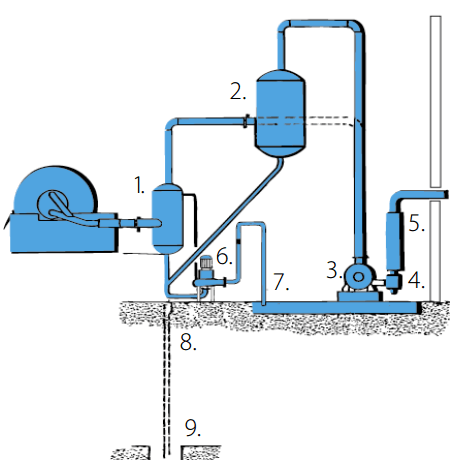

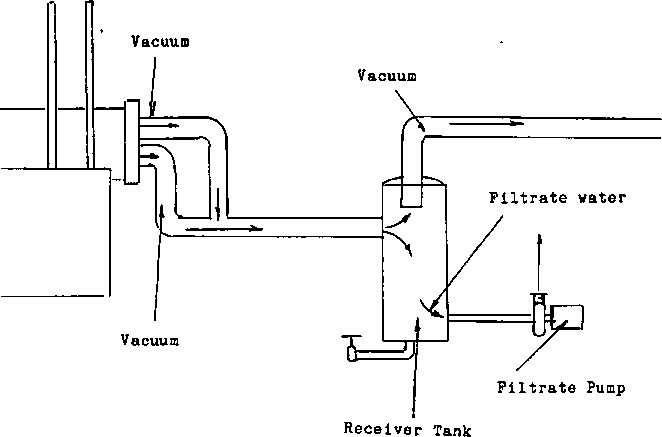

The last equipment that I want to talk about that is part of the filtering system is the FILTRATE PUMP and the VACUUM PUMP. The filtrate pump is the pump that removes the water that is filtered out of the concentrate. It works with the filter and vacuum pump in a circuit. How these three work together is this way. When the vacuum is applied to the filter sectors, to remove the water, the water is pulled towards the vacuum pump. This water is referred to as FILTRATE WATER because it has been filtered out of the concentrate. To have the water enter the vacuum pump is not

desirable so a RECEIVER TANK to trap the water is attached to the vacuum line. A receiver tank works like this.

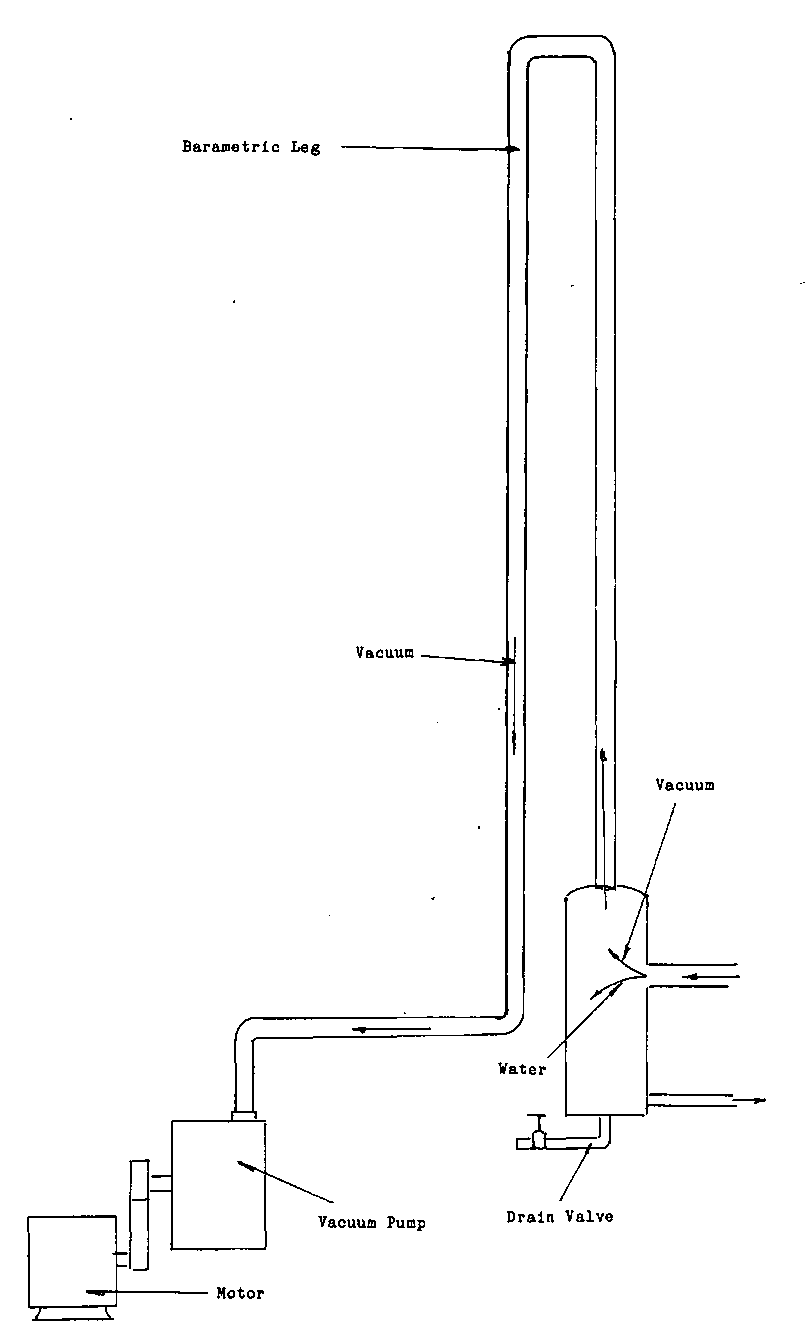

The vacuum line from-the filter will enter the body of the receiver tank, near the top. The vacuum line out will be situated at the very top of the tank. At the bottom of the tank there will be an outlet that will lead to the filtrate pump. As the water is pulled down the line it enters the filtrate tank. Because water is heavier than air it will fall to the bottom of the tank to be pumped away by the filtrate pump. If the vacuum pump is of the type that moisture must not be allowed in to, a BAROMETRIC LEG will form part of the vacuum line to the vacuum pump.

A perfect vacuum can lift water only so A barometric leg is a portion of the vacuum line that is lifted to a height greater than the vacuum is able to lift the water. This distance changes of course with elevation. If the Vacuum pump is on the top of a mountain 7000 feet high it will lift water higher there than one at sea-level.

The danger for the vacuum pump here is that if the filtrate pump should stop, or have the amount that it is capable of pumping reduced, then the filtrate water will begin filling the barometric leg. Once the leg is full, the vacuum pump will be able to lift the water over the top of the leg causing extensive damage to the pump.

For the operator to prevent this all he has to do is check the receiver tank. On the bottom of the tank, there is normally a valve. If this valve is opened and the water drained from the tank when the filtrate pump and the vacuum pump is shut down, the amount of water that comes out will tell the operator if the filtrate pump is pumping to capacity.

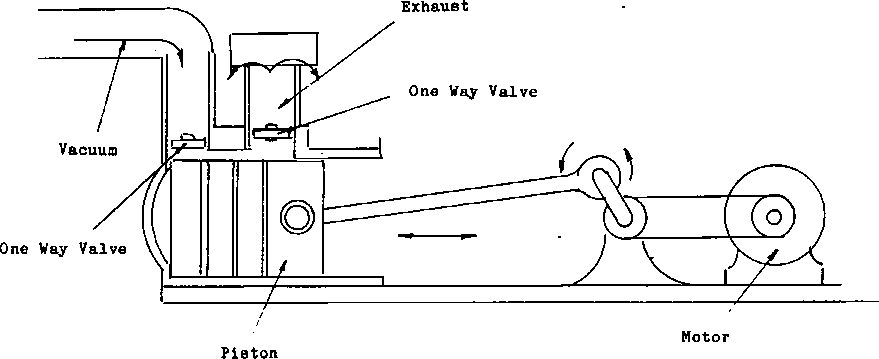

There is a type of vacuum pump that runs in water, this one is termed a WET VACUUM pump. If this type is in use, then the barometric leg isn’t necessary as water won’t harm this type of pump. Unfortunately this will not do away with the need of a filtrate pump and a receiver tank. A hole in the filter sector hag will allow concentrate to the sucked into the system. The filtrate pumps job is to ensure that the concentrate doesn’t get into the vacuum pump. In both cases the holes that do appear in the filter sectors have to be repaired immediately. Not only does the loss of vacuum effect the performance of the filter, the abrasiveness of the concentrate lowers the life of the filtrate pump. Once the Filter has extracted all of the water from the concentrate that it can, the concentrate will go to the next stage of Dewatering, the DRIER.

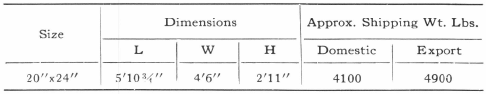

Continuous Centrifuge

SEPARATION of solids from liquids is one of the necessary steps in many metallurgical, manufacturing and processing plants. The Continuous Centrifuge is designed to meet these requirements incorporating heavy duty design to ensure continuous uninterrupted operation and reduce maintenance costs to a minimum.

Through the principle of conveying moist solids through a fast rotating perforated cylinder, remarkable dewatering can be achieved with practically no loss of solids. A filtrate free of solids is also recoverable. Because of the relatively short interval of from 3 to 30 seconds between the time the slurry enters the centrifuge and the discharge of solids and filtrate, large capacities are possible. Capacities range from several hundred pounds to several tons per hour depending on the materials handled. Power costs are small, being as low as 2½ to 3 kilowatt hours per ton.

Additional data gladly furnished upon request.

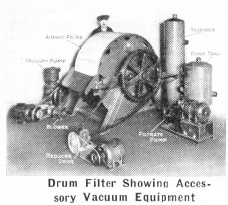

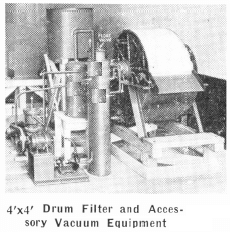

Vacuum Equipment – Filter and Utility

Filter and Utility Vacuum Equipment has been developed to meet the requirements of various filtering or other problems requiring the use of vacuum. The arrangements available have been designed to supply the most economical and efficient operation possible.

In the operation of vacuum equipment for filtering, the moisture is drawn through the rotating filter valve to a filtrate receiver where the liquid is removed by a centrifugal pump. Vacuum is maintained by a standard dry vacuum pump through a foam trap placed above the barometric seal at an approximate height of thirty feet. The centrifugal pump for the filtrate is not required in cases where the barometric height can be utilized. Accessory equipment summarized, consists of: vacuum receiver, filtrate pump, vacuum trap, low pressure blower, and dry vacuum pump.

In addition to vacuum systems for filtering, various capacities of vacuum systems are available to provide vacuum for precipitation plants or general uses. In some instances it is most economical to utilize a vacuum-pressure combination arrangement.