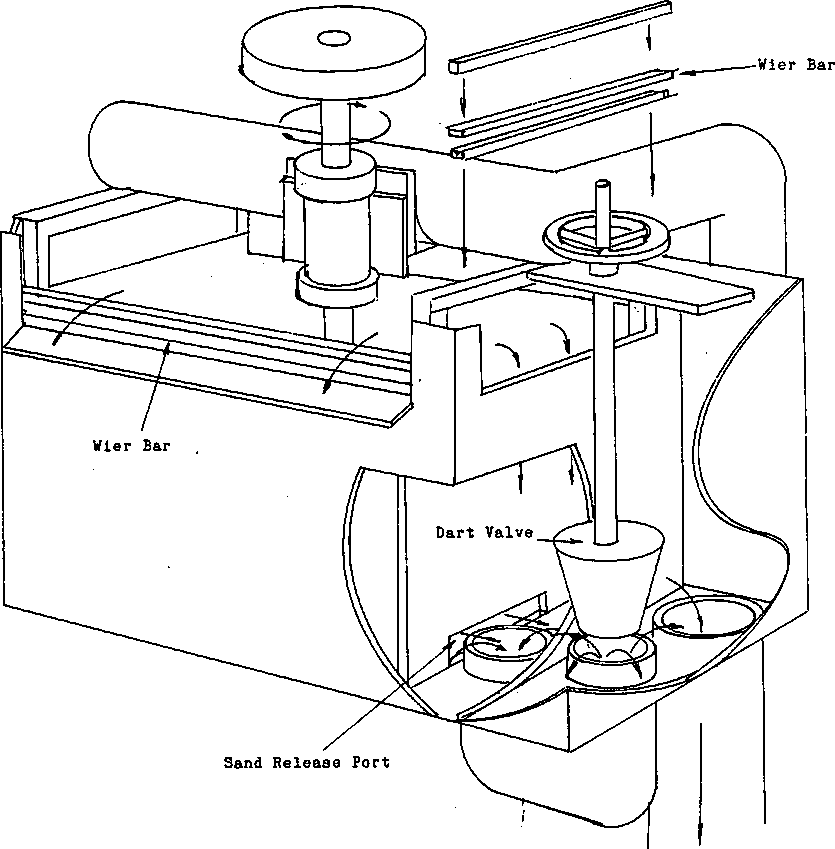

In every cell there is the need to allow the SANDS to escape. The sands are the particles that didn’t become ground fine enough. NO matter how efficient the classifier is it will not be one hundred percent effective. There will always be aware factor, where in the circuit that the cell is, and operator error to introduce the coarser material into the cells. To allow this material passage through the cells a SAND RELEASE PORT is introduced into the design. The diameter of the port will depend upon the volume of ore that is treated in the circuit. To assist in keeping the ore in suspension and to help the coarse material through the port, the impeller distributor plate has a passage way between the port and the impeller.

The impeller as it turns causes a vacuum to be generated pulling the coarse material through the port and distributing it through the cell. This particular type of cell has a choice of methods to introduce the air to the cell. First the vacuum generated by the moving impeller will cause an air flow between the impeller shaft and a collar that was designed for this purpose. The same cell may be what is known as SUPERCHARGED. Instead of allowing the air to be introduced by the action of the impeller, the collar is capped and the air is forced into the cell by an air blower.

Often this type of cell will be used for material that requires a long retention time with a deep froth column.

When this is the case the required volume of air may not be enough to generate the proper surface movement to allow the bubbles to form correctly. To fix this, paddles will he added to pull the froth off of the cells and allow space for the new bubbles to form.

The other type of cell that I will describe is the SUPER CELL.

Instead of having one impeller for each cell there will be a number of impellers in one long cell or tank. Using this method the need for the sand release ports are limited to the discharge of the bank of impellers. This means the diameter of the ports will be larger making it easier to control them. Because of this the cell can handle -much coarser material and at a higher rate of tonnage.

Instead of having one impeller for each cell there will be a number of impellers in one long cell or tank. Using this method the need for the sand release ports are limited to the discharge of the bank of impellers. This means the diameter of the ports will be larger making it easier to control them. Because of this the cell can handle -much coarser material and at a higher rate of tonnage.

The air is introduced through the impeller shaft to create the froth which is guided to the overflow by cell dividers. These are just steel plates that extend part way into the slurry to make the froth flow outwards.

The pulp level is controlled at the discharge end of the cell by controlling the sand release ports at the bottom of the cell to allow more or less material out or by raising the top edge of the discharge point to keep more in. This is done by adding or subtracting WEIR BARS, these are simply steel bars of varying thicknesses that are added to the lip of the cell. The weir bars are also added to the front of the cells to control the depth of the froth at each of the impellers.