For some time past the company has been experimenting with a view to finding the best method of concentrating the sulphide ore before smelting. The first test-mill consisted of two sets of rolls, one Chilean mill, one Hardinge conical mill 6 ft. diam. by 12 in. cylinder, Richards hindered-settling classifier, Deister tables, some kind of vanner, and a 50-ton Minerals Separation flotation machine of standard type (Hoover’s single-level apparatus). This mill was situated in Arizona close to the Joe Bush shaft, on top of the orebody, and is now dismantled. It is understood that good results were obtained.

On a change of management taking place, a new test-mill was erected near the old leaching plant of the Black Warrior Copper Co., about 1½ miles from the new twin-shafts through which all ore will be hoisted when the large mill is running. This mill will be the largest, or rather will handle the largest tonnage, of any mill in the world, namely, 15,000 tons per day. It adjoins the test-mill as can be seen in the photograph published in the Mining and Scientific Press of May 29. The crushing and concentrating capacity of the test-mill is about 1000 tons per day, but it is limited by the capacity of the classifiers, elevators, etc.

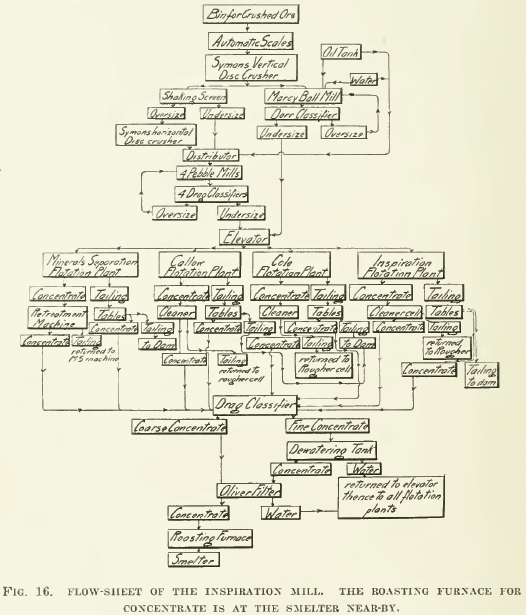

The ore is at present hoisted through the Scorpion shaft and broken in a ‘K’ Gates crusher close to the shaft. From there it is conveyed to the 30.000-ton flat-bottomed steel and concrete bins attached to the crusher-station at the new shafts. It is then transported to the test-mill in Ingolds by dump-cars (each having a capacity of 60 tons) drawn by steam-locomotives on a standard-gauge railway. A part of the new mill-bins (which are of steel and trough¬shaped) is set aside for the use of the test-mill. On leaving these bins the ore falls upon a tray-conveyor, then to an inclined rubber- belt conveyor, where it is automatically weighed. At the head of this conveyor there is a magnetic pulley that removes pieces of iron and steel which may have got mixed with the ore. At this point there is a grizzly and a 36-in. Symons vertical-disc crusher.

From here an incline-conveyor carries the ore to the top of the test-mill, where it is divided into two streams, one going to a shaking screen from which the oversize falls into a 48-in. Symons horizontal- disc crusher, where it is crushed dry, and the other to a 5 ft. 6 in. by 8 ft. diam. Marcy ball-mill, where it is crushed wet without previous screening. The product of the Symons machine is fed to pebble-mills without any classification, being distributed in varying proportions by a mechanical device. This consists of a fixed horizontal circular vessel 103 inches in circumference, divided into four sections by vertical sheet-iron partitions that can be adjusted to give segments of any size, thus varying the feed to each mill as desired. By measuring the number of inches of circumference given to each division the proportion of feed going to each mill can be calculated. Above this receptacle there is a vertical crooked revolving iron pipe through which the feed comes from the Symons machine after being mixed with water. The revolution of the feed-pipe causes the pulp to be discharged into each division of the distributor in turn. In the bottom of each division is a hole through which the feed passes to launders leading to the pebble-mills.

The following kinds of pebble-mills are installed:

- One 20 by 6-ft. Chalmers & Williams quick-discharge tube-mill with herring-bone gear engaging with pinion on a shaft directly driven through a flexible coupling by an electric motor.

- One Hardinge conical mill, 10 ft. diam., with cylindrical part 28 in. long driven through spur and pinion by two-belt transmission from motor.

- One Hardinge conical mill, 8 ft. diam., with cylinder 72 in. long, with herring-bone gear engaging with pinion on shaft direct driven by motor.

- One Hardinge conical mill, 8 ft. diam., with cylinder 36 in. long, driven in the same manner as No. 3.

- One Hardinge conical mill, 8 ft. diam., with cylinder 44 in. long, driven in same way as No. 3 and 4.

Both silex and El Oro linings were tried in the cylindrical part, and pebbles set in cement in the conical part; and, in one mill, steel plates, which, however, did not last long.

Each pebble-mill has a drag-classifier attached, and the oversize in the product, except in the case of the tube-mill, is returned by a bucket-elevator to the mill from which it came. In the case of the tube-mill the oversize is returned to the mill by the drag-classifier, which is parallel with the mill. Both Danish and California pebbles have been tried.

The product of the Marcy ball-mill is classified in a duplex Dorr classifier, and the oversize returned to the same machine. This, as a fine crusher, has a capacity of about 13 tons per hour. Of the final product only about 1% remains on a 48-mesh screen. The mill is simply a strongly built cylinder supported on trunnions, contains about 10 tons of chrome-steel or manganoid balls, and is revolved at 22 r.p.m. It was formerly fed through the trunnion, then three scoops were attached, but now one large scoop is used. It is lined with manganese-steel plates and driven through spur and pinion by belting from a 200-hp. motor, using about 140 kilowatts. The discharge is at the opposite end to the feed-inlet and passes through grates composed of steel bars placed close together. The discharge area is more than half the entire end of the mill. It will thus be seen that it differs essentially from the Krupp ball-mill, in which the screens are placed around the periphery and the pulp has to pass through two screens before escaping. The pulp leaving the ball-mill contains about 40% of moisture. This is diluted before entering the Dorr classifier. The overflow from the classifier consists of 2½ to 3 parts of water to one of ore.

The power required to drive these different mills, their capacity, consumption of balls, pebbles, and liners are, of course, known only to the management, but it is significant that in the new mill all crushing will be done by Marcy mills.

Among other crushing machines that have been tried are the Bradley roller-mill, Symons roller-mill, Overstrom mill, and Allis- Chalmers hammer-mill. No rolls or Chilean mills, Krupp mills, or Marathon mills were tried in this plant.

The products of the Marcy mill, and such of the pebble-mills as are running, are united and elevated sufficiently high to flow to all the flotation plants without undergoing any preliminary table or vanner concentration. The feed is distributed to the flotation plants in the following way: It flows into the centre of a horizontal, circular, revolving apparatus of sheet-iron divided into five concentric circles or rings. Each circle has 20 holes in the bottom, and the proportion of feed to each flotation plant is regulated by opening the proper number of holes and allowing the pulp to enter a launder along which it flows to the flotation plant. Thus if the ring that receives the feed intended for one particular plant has 15 holes plugged and 5 open, this plant is, of course, receiving 25% of the total feed, and the actual tonnage passed through it can be calculated.

Automatic samplers, worked by a water balance, are used throughout the mill. All assays are done by the electrolytic method, using rotating anodes.

Most of the flotation ‘oil’ is added to the pulp at the head of the mill, being fed from a tank by a small bucket-elevator driven by a shaft having a cone-step pulley, so that the speed of the elevator and the quantity of ‘oil’ can be varied to suit the tonnage of ore being crushed. This is much more satisfactory than letting the ‘oil’ drip from a can. Any additional reagent that may be required is added at each flotation plant by dripping from a can.

The following methods of flotation have been tried:

- An 8-compartment Minerals Separation machine of standard type (as described in Hoover’s book on flotation), having a nominal capacity of 600 tons per day. The agitation compartments are 3 ft. square, and the flotation compartments or spitzkasten, 5 by 3 ft. The spindles are driven through enclosed bevel-gearing by a pulley on a horizontal shaft. The overflow from the first six compartments was sent to the concentrate-bins without ‘cleaning’ or further treatment designed to raise the grade by eliminating insoluble matter and the overflow from the last two compartments was returned to the head of the machine. This machine was discarded.

- A 12-compartment Minerals Separation machine of standard type, of the same capacity and driven in the same manner as No. 1, the additional compartments being intended to prolong the treatment. At first the concentrate and middling were dealt with as in No. 1 machine, but afterward the overflow from all compartments was ‘cleaned’ in (3). next described.

- An 8-compartment 50-ton Minerals Separation machine of standard type, the spindles being driven by half-crossed belts from pulleys on a horizontal shaft. The overflow from all compartments was sent to concentrate-bins, and the tailing was returned to the head of No. 2 machine. This concentrate contained about 30% copper. These two machines were in use until recently.

- An 8-compartment Minerals Separation machine of new type, known as a ‘sub-aeration machine.’ The agitation compartments were covered on top, and both mechanical agitation and compressed air were used. The agitation compartments contained cast-iron baffle-plates fixed to the sides, and the impellers were different from those used in the standard machine, but the spindles were driven in the usual way. The discharge from the agitation compartments to the flotation compartments was high up. The air used for the aeration of the pulp was introduced through a hole in the bottom of each agitation compartment at a pressure of about 2 lb. per square inch. It did not pass through any porous medium. This machine had the usual valves and suction-pipes in the bottom, but was afterward altered to

- a machine of the Hebbard type, with agitation gear of the standard Minerals Separation pattern, but with horizontal discs in place of the usual screw-impellers. Each spindle makes about 300 r.p.m. In the Hebbard machine as used in Australia the agitators are driven from below. There are no spitzkasten, the overflow of concentrate-froth taking place from the agitation compartments. Consequently there are no suction-pipes and valves in the bottom, and no plugs to draw and replace when a stoppage takes place. The wooden partitions between the agitation compartments have been removed and cast-iron baffle-plates about 15 in. high substituted. Air is blown through eight holes in the bottom as in No. 4 machine (described above) and water under pressure is used to prevent pulp from entering the air-pipe. On a feed of about 300 tons per day this machine has given good results, and is still in use. The low-grade concentrate made by this machine is ‘cleaned’ in another machine of standard type.

- A Towne-Flinn plant, or bubble-column concentrator with a nominal capacity of 50 tons per day. This consisted of (1) Pachuca agitator in which the pulp was mixed with oil, (2) a cast-iron vertical cylinder with a bottom of carborundum. The oiled pulp is fed into the top of the cylinder through a pipe that delivers it below the surface. Air at a pressure of 5 lb. per square inch is blown through the carborundum. Bubbles are formed, that adhere to the oiled sulphide particles, forming a froth overflowing at the top of the cylinder into a launder, whence it flows to (3) a similar cylinder at a lower level, where it is ‘cleaned.’ The tailing from the first cylinder escapes through a hole in the middle of the carborundum and flows through a goose-neck hose (by which the water-level in the first cylinder is regulated) to (4) another cylinder where it receives similar treatment and more concentrate overflows. This concentrate also is re-treated in the same cylinder as the concentrate from the first cylinder, and the tailing from this cylinder or ‘cleaner’ is returned to the Pachuca agitator at the top of the building by a centrifugal pump. The air is furnished by a Roots blower. This plant was dismantled.

- A Callow plant consisting of (1) Pachuca agitator 18 ft. deep by 4 in. diam., (2) five cells, each 8½ ft. long by 2 ft. wide, with

nominal capacity of 50 tons each per day, (3) one cleaner-cell 12 in. wide, (4) one air-compressor, (5) one receiver, (6) Connersville blower with a displacement of 3.3 cu. ft. of air per revolution, (7) two 3-in. centrifugal pumps, (8) 30-hp. motor.

Mr. Callow’s letter in the Mining and Scientific Press of May 29 fully describes his process, so I need not go into further particulars, except to say that during the past few months the plant has been run without the Pachuca agitators; but this is by no means advisable. This plant has been running for about nine months and has given better results than any other that has been tried here. Forty of these cells are being installed in the new mill.

- A machine invented by David Cole, of Morenci, Arizona, consisting of rectangular sheet-iron tanks with pipes laid horizontally in the bottom. The upper half of these pipes is composed of carborundum, and air from a blower is forced through them with the same effect as in the Callow, Towne-Flinn, and other pneumatic processes. Perforated wrought-iron pipes wrapped with flannel or canvas have also been used. The tailing from the first tank is re-treated, and the concentrate from all tanks is re-treated in a ‘cleaner.’ This plant is still running. A similar machine is in use at Morenei, and one is being built at Cananea, Sonora.

- The company’s metallurgist has devised an apparatus intended to combine the best points of the other machines, but without infringing on any patents, except those of the Minerals Separation American Syndicate, from whom the company holds a license. It is called the Inspiration machine. At first it resembled a Callow apparatus with an almost flat bottom, the air being blown through canvas, but the froth overflowed at one side of the cell only, and there were partitions which, however, did not reach the bottom. It was twice as long as the ordinary Callow cell. The first concentrate was re-treated in a smaller machine of the same type, and the tailing from this machine was, as usual, returned to the ‘rougher’ cell. Recently other porous media for false bottoms have been tried. The machine is still in the experimental stage.

It will thus be seen that the company has spared neither time nor money in endeavouring to find the best flotation process. The test-mill has been working since January 1914, and about 50 flow-sheets have been tried. In the laboratory there are 6 small flotation machines of the Minerals Separation type in almost constant use.

The tailing from all the flotation plants is run over tables, those in use being “Wilfley, Deister Machine Co.’s double-deck simplex sand concentrator, Deister Machine Co.’s four-deck table, Deister slime, table, and Deister Concentrator Co.’s double-deck table. At one time, the ore was concentrated on tables before going through the flotation process, but this was not found suitable for the Minerals Separation process, as it left too little mineral in the ore, and for this and other reasons it was discarded. The mineral saved on the tables is mostly pyrite. The 234 tables in the new mill are Deister Machine Co.’s double-deck type, the same as used in the Miami Copper Co.’s mill. No tests were made with any kind of vanner. The sand and slime were run over the same tables without classification, but this will be altered in the new mill.

The tailing from the tables flows to the dam, the retaining-wall being built by allowing the coarse sand to escape through cones or inverted pyramids attached to the tailing-launder.

The concentrate from all flotation plants and the tables, containing about 28% copper, 16% iron, and 26% insoluble matter, goes to a drag-classifier. From there the coarse concentrate goes direct to an Oliver filter and the fine to a V-shaped settling-tank, thence to the filter. The concentrate, after filtering, still contains a good deal of moisture. It is trammed to a bin adjoining a branch of the standard- gauge railway and loaded into bottom-discharge steel cars belonging to the International Smelting Co. Formerly it was sent to El Paso, Texas.

“Water for the mill and domestic purposes is obtained by pumping from wells in the flat country about three miles distant. A large concrete reservoir has been built on a hill near the mill. Electric power is obtained from the power-house at the Roosevelt dam about 40 miles distant, belonging to the U. S. Reclamation Service, and the service is fairly satisfactory. The Inspiration company has an interest in the power-house at the International smelter near-by, where, in case of emergency, a supply of electricity can be generated by steam from waste heat from the reverberatories and from oil-fired Stirling boilers.

As mentioned in the annual report of the company (a summary of which appeared in the Mining and Scientific Press of May 1, 1915), 172,722 tons of ore was treated in this mill in 1914, so, although only a test mill, it handles a fairly large tonnage. During the month of February 1915, 90.3% of the copper occurring in the form of sulphides was recovered. The mill has been visited by mining men from all parts of the world.

https://archive.org/stream/flotationproces00unkngoog#page/n96/mode/2up