The process depends upon the fact that minerals with a metallic lustre, when treated in the form of a wetted pulp, adhere to oil, while earthy minerals do not. Two distinct operations are involved; first, the separation of the metallic mineral from the gangue by means of oil; second, the extraction of the mineral from the oil.

“The ideas underlying the first operation were patented by John Tunbridge of Newark, N. J., in 1878. In 1886 Carrie J. Everson, of Chicago, contributed the idea that the concentration was aided by the presence of an acid solution, and patented the same. But the absence of a successful method of separating the mineral from the oil prevented the practical application of these early patents. Burning the oil was tried, but this left a difficult residue to treat, and the large consumption of oil made the method too expensive. Settling the mineral out by thinning the oil with gasoline, ether, carbon- bisulphide, etc., also proved too expensive, and it was not until July 1900 that this difficulty was overcome, when Mr. Francis E. Elmore, of Leeds, England, accomplished the separation by means of a centrifugal machine, similar in most respects to those used in sugar factories and in milk and cream separation. This contribution by Mr. Elmore, then, made the process feasible.”

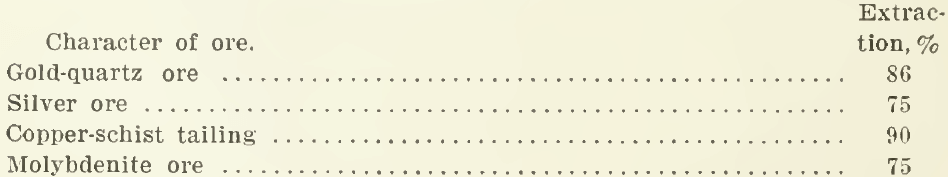

They give an illustration of the plant designed by the Oil Concentration Syndicate and describe the operations. Their own apparatus is shown in photographs and they give details of the tests made on various ores. In brief, they obtained the following results:

They describe the nature of their experiments and comment on the facts disclosed in a most intelligent way. We quote the salient paragraphs.

“In making a test, the ore is first crushed to the desired fineness, and the proper charge is thoroughly wetted in the solution to be used (usually water), thus forming a thin pulp. The oil is next added and the whole charge thoroughly mixed. This mixing, or agitation, can be done in two different ways: The charge may be agitated very gently, the oil being kept in a single lake, and broken up as little as possible consistent with a thorough contact of pulp and oil; or the charge may be agitated so violently as to dash the oil up into a foam or froth, full of air bubbles: thus a very thorough contact of oil and pulp is obtained.

“Three methods of mixing may be used.

- By inverting the tube several times, thus allowing the ore to fall through the oil.

- By rotating the tube in a horizontal position, thus throwing the pulp up on to the surface of the lake of oil.

- By violently shaking the tube, thus producing the foam effect or at least shattering the oil into small globules.”

“The solution used in the concentration is a matter of some importance. Water is, of course, used whenever possible, but certain other solutions have important advantages. As before stated, an acid solution is found advantageous. It cleans the metallic surfaces by dissolving the metallic oxide coatings that may have formed on them. It increases the specific gravity of the solution, and it aids in producing the foam effect, which is due to the generation of certain gases.

As before stated, the specific gravity of the average oil used is about 0.9 and water 1.0, leaving a difference of about 0.1 for buoyancy or carrying capacity of the oil.

The idea at once suggests itself that if a denser solution be used, the carrying power of the oil will be increased correspondingly. A salt (NaCl) solution, for instance, gives excellent results. A saturated solution of NaCl at 20°C., containing about 27% NaCl, has a specific gravity of 1.204. This gives a difference of 0.3 between the specific gravities of the oil and of the solution, and a carrying capacity of the oil threefold greater than with water alone. Not only does it give greater buoyancy to the oil, but it also aids materially in producing the foam effect, and probably aids in brightening the metallic surfaces.”

As a conclusion to the above experiments, the following suggestions and inferences are appended:

- As Regards the Wetted Pulp. As far as could be determined, particles with either metallic or non-metallic surfaces, when in a dry state, alike adhere to the oil. Furthermore, there is no affinity of oil for water, as shown by the fact that an oiled surface cannot be wetted. Hence if a metallic particle be thoroughly wetted, a water surface and not a metallic surface is exposed to the oil; and the former, as before stated, has no affinity for the oil. It is evident then that the water film must first be displaced before the oil and mineral can come in contact with each other. This displacement is hardly probable if the water film is in intimate contact with the particle, and it seems more probable that the differentiation is due to the fact that non-metallic surfaces are, and metallic surfaces are not, actually wetted. If this be the case, a careful study of the relative wetting of different surfaces would be an important line of investigation.

- The ratio of the exposed surface to the weight of the particle should be as large as possible, because the total adhesive force is increased with an increase of the surface exposed to contact with the oil. This condition is best realized when the mineral breaks up into thin flakes. It is evident from this that a knowledge of the fissile character of the minerals in question is important.

- One fundamental difficulty involved in this process is that it undertakes to concentrate and float a heavy metallic mineral, and sink the lighter gangue minerals, but this point is not necessarily fatal to the process. It is evident, however, that the heavier the gangue and the lighter and more fissile the metallic minerals, the better the ore is adapted to this method of concentration. This is a direct reversal of the ideal conditions for jig or vanner concentration.

- Another characteristic of the process is the fact that the ratio of concentration is usually small, due to the large amount of gangue occluded by the oil and carried into the concentrates. This difficulty is increased by sliming the gangue minerals. Sliming of the metallic minerals is no disadvantage.

FOAM EFFECT

The foam effect is produced by a violent agitation, especially in acid or salt solutions. This throws the oil into a froth, which is heavily charged with air or other gases. This gas, of course, gives a greatly increased buoyant force. The oil in this condition assumes a certain load of mineral and holds it in a very stable condition. The charge does not settle and overload on standing as in the case of the lake effect. The foam effect is best adapted for light flaky minerals, such as molybdenite.

The work above outlined suggests many lines of further investigation, and as these come to be worked out, the process will become more valuable and of more general application.”

It is clear that they had a good idea of the usefulness of the froth, and how to make it. In the employment of salt and acid, they anticipated G. D. Delprat, for his British patent for the use of salt and sulphuric acid was taken out on December 11, 1903, that is, two months after this article was published. The early work of C. V. Potter (patented on January 14, 1902) and G. D. Delprat (beginning with a patent dated November 28, 1902) did not involve the use of oil, but the generation of gas in the pulp to form bubbles. Alcide Froment (under patent dated June 4, 1902) connected the oil and bubble ideas, and it is his patent that forms the basis of the Minerals Separation process, to which in 1905 (and particularly November 6, 1906) were added several patents obtained by H. L. Sulman, H. F. K. Picard, and John Ballot, for the agitation-froth process. Thus these three students at the University of California had touched upon an idea destined to be of the greatest importance in metallurgy, but they did not know it. In the very same issue of their Journal of Technology there appears an article on ‘The Method of Obtaining Letters Patent.’ The irony of the juxtaposition is evident now. We note that the manager of this student publication was Arthur H. Halloran, then a junior in the University. He became a member of the staff of the Mining and Scientific Press after graduation and for some time after his father, J. F. Halloran, sold the control of the paper to the present writer. However, it may not be so surprising that these young fellows failed to appreciate the importance of the suggestions obtained in the course of their experimental work, but it is truly remarkable that a keen investigator like their professor, the late Samuel B. Christy, should have overlooked it, at a time, too, when he himself was at work on kindred research, more particularly in cyanidation. It may have been his absorption in the one part of the subject that prevented him from obtaining the right focus on these— now, to us—deeply suggestive experiments.