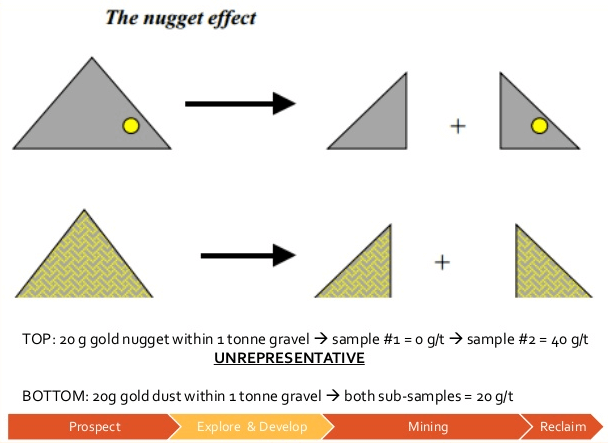

In typical gold deposit (with gravity gold) the variations are so great and the values are so low, any attempt to divide a sample by taking alternate shovels, mechanical splitting, or by other means will invariably yield erratic results. Rather than set out supporting theory which at best would be academic, two examples are offered to show what actually happens. One is based on a laboratory experiment and the other on field practice at an operating mine. First consider the laboratory experiment to explain the Gold Nugget Effect that happens in Sampling and sample preparation.

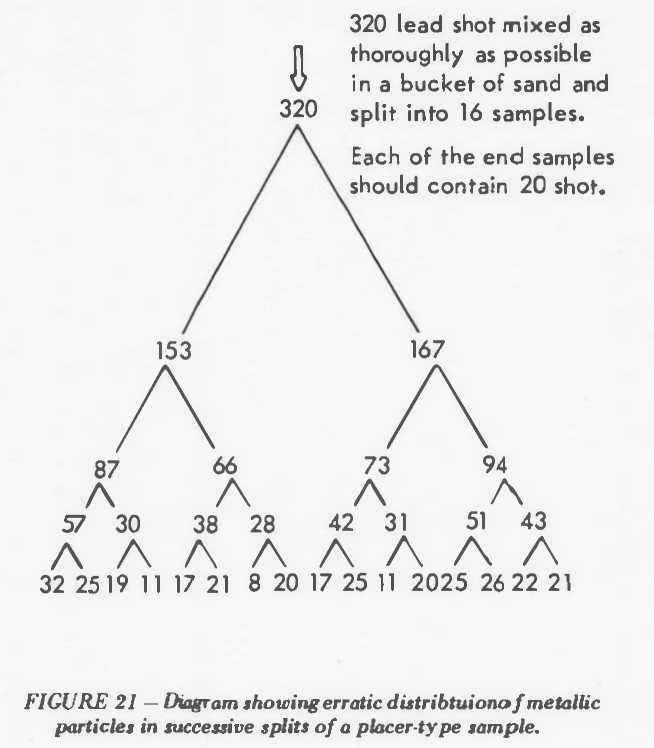

Referring to Figure 21, assume that the bucket of sand weighs 60 pounds and that instead of lead shot it contains 320 particles of placer gold weighing 0.1 milligram each. The first split yields two 30-pound samples with indicated values of 153 and 167 per cubic yard, a spread of 14 per cubic yard.

The second split yields four 15-pound samples with indicated values of 87, 66, 73 and 94 per cubic yard; a spread of 21 cents per cubic yard.

The third split yields eight 7½-pound samples with values ranging from a low of 28 to a high of 57 per cubic yard; a spread of 29

The fourth split yields sixteen 3-¾-pound samples with values ranging from a low of 8 cents to a high of 32 per cubic yard; a spread of 24.

As splitting continues, the spread in indicated value becomes progressively greater. On the fifth split, for example, (not shown) the indicated values ranged goes wild.

Data from a recent study by the United States Geological Survey (Clifton, 1967) confirm that variances shown in the foregoing example are typical of those found in practice.

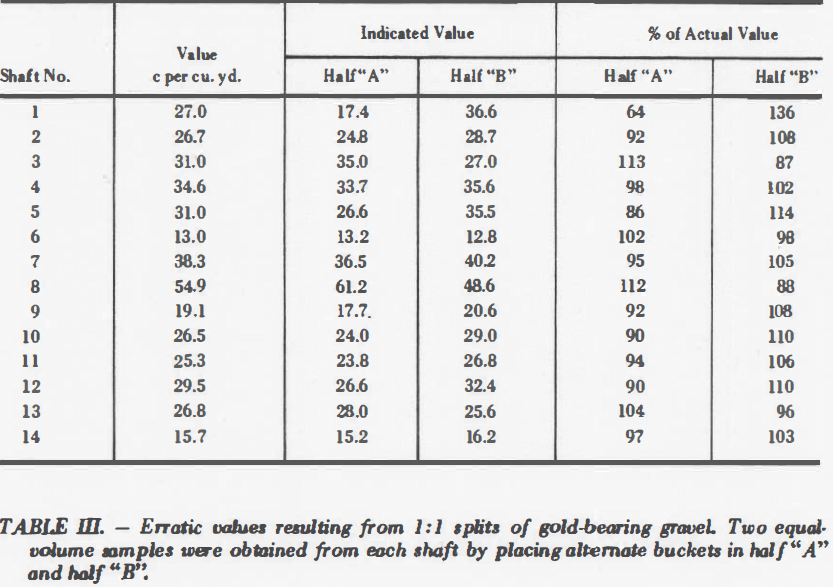

The second example has been taken from the prospecting records of an operating company. In this case the gold-bearing gravel excavated from each of 14 shafts was divided as carefully as possible by taking alternate buckets as the work progressed. The hand-dug shafts were 40 inches in diameter and ranged from 30 to 40 feet deep. The individual halves, averaging 7¼. cubic yards each, were washed separately. Results are shown in the following tabulation:

The foregoing examples show that the splitting of gold placer samples should be strictly avoided unless there is some very special reason to divide a sample or reduce its volume before washing or other treatment. In cases where this must be done, the mineral examiner should be fully aware of the erratic and probably misleading results likely to follow. Any divergence from normal procedure should, of course, be noted in the sampling records and in subsequent reporting.

When dealing with fine-size placer materials having a low unit-value, such as magnetite or ilmenite sands, a substantial reduction of the bulk sample or of its concentrate by mixing and splitting is generally a proper procedure and a common practice.