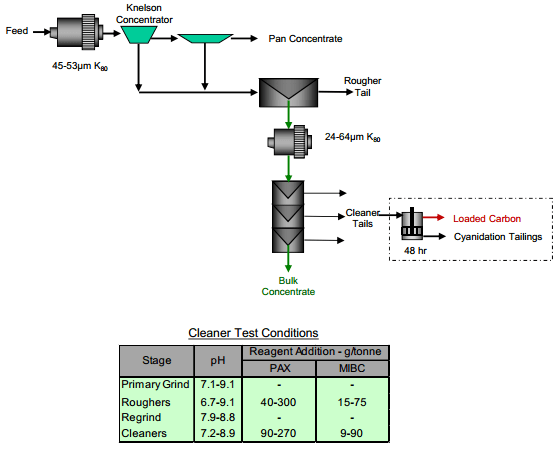

To further evaluate the process of Gold Recovery by Gravity, Flotation and Carbon-in-Leach Cyanidation, some cleaner tests with regrind of the bulk rougher concentrate, were conducted. Rougher flotation concentrates were reground to improve leach kinetics. The regrind sizes for these range of tests were not optimized. Regrind discharge sizes of between 24 to 64µm P80 were obtained.

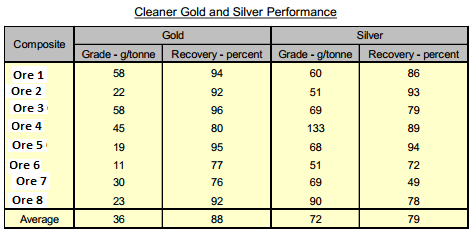

The gold grade of the combined pan concentrate and cleaner concentrate ranged between about 11 and 58 g/tonne for various lithology composites, averaging about 88 percent recovery of gold in the feed. The silver grade was between 51 and 133 g/tonne, with an average recovery of about 80 percent.

A Master Composite combined pan concentrate and cleaner concentrate gold grade was about 47 g/tonne with about 92 percent recovery. The silver grade of the combined concentrate was about 63 percent with about 77 percent recovery.

CIL testing of the cleaner tails from Master Composite Test extracted about 37 percent of the gold and 40 percent of the silver in the cleaner tails. Overall, this would increase gold and silver recovery by about 1.6 and 2.4 percent, respectively.

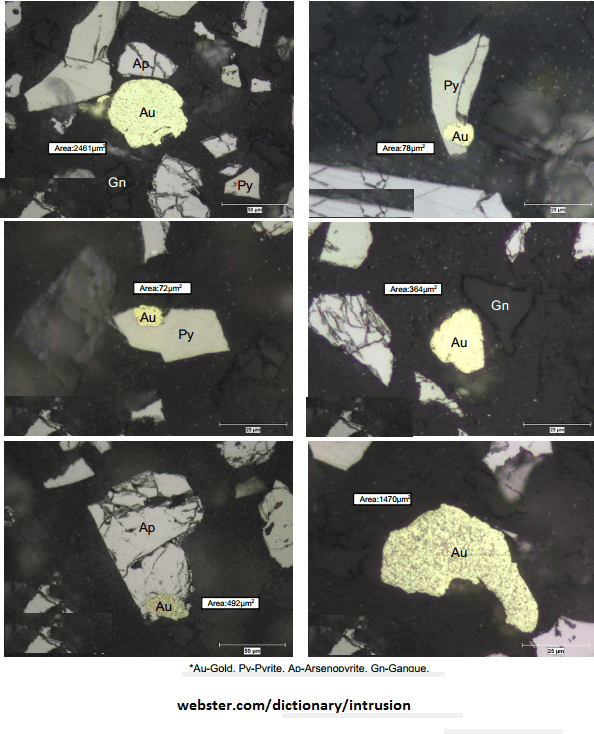

The total sulphide mineral content, in the lithology composites, accounted for between 0.6 and 55 percent of the sample mass. The majority of sulphide minerals present were pyrite, arsenopyrite, pyrrhotite and chalcopyrite. On average about 61 percent of the sulphide minerals were present as pyrite, therefore about 35 percent was present as arsenopyrite. Arsenic was essentially only associated with arsenopyrite, with the exception of Ore 7, which had about 28 percent associated with iron-arsenic oxides, which may be difficult to recover using conventional flotation conditions.

Liberation of arsenopyrite and pyrite/pyrrhotite averaged 82 and 76 percent, respectively. This would be considered sufficient for good rougher separation. There was a significant amount of interlocking with pyrite and gangue, being on average about 20 percent. These binaries contained, on average, about 50 percent pyrite which should be recoverable under suitable flotation conditions.

Two principal flowsheets were evaluated in the current test program. The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration. While gravity separation and flotation of the samples produced good gold and silver recoveries, the subsequent cyanidation of the concentrates did not provide any significant improvement in gold performance, on average, over Whole-of-Ore CIL testing.

The gravity/flotation flowsheet with cyanidation of the respective concentrates recovered an average of about 59 and 69 percent of the gold and silver, respectively, in the feed across all eight lithology composites. Whole-ofore CIL extracted an average of about 61 and 38 percent of gold and silver, respectively. These results would indicate that there is some degree of refractory gold, which would require alternative processing to recover.

Gravity/cleaner tests with regrind of the bulk rougher concentrate were conducted. The gold grade of the combined pan concentrate and cleaner concentrate ranged between about 11 and 58 g/tonne for the eight lithology composites, averaging about 88 percent recovery of gold in the feed. The silver grade was between 51 and 133 g/tonne, with an average recovery of about 80 percent.