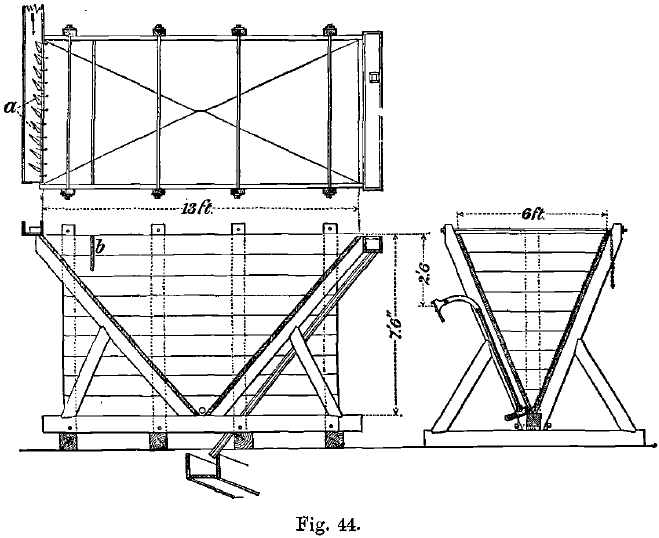

Gold Settling Boxes are of the same shape as the spitzkasten or pointed boxes introduced by von Rittinger. They are for the purpose of allowing the sand and mineral in suspension in a flowing current to settle, so that the part of the water not needed in the subsequent treatment of the ore may be run off; if it is desirable, this excess of water is available for use over again. These boxes will deliver a small stream of thick concentrated pulp at the bottom and give an overflow of almost clear water at the top. The boxes manufactured by Messrs. Fraser & Chalmers are shown in plan and elevation in Fig. 44. The main points observed in the construction of these boxes are as follows:

The sides are at an angle of at least 50° to the horizontal, to insure the uninterrupted descent of the slimes. The pulp is delivered evenly across the end of the box by means of some such arrangement as the movable tongues (a, Fig, 44). Surface currents are prevented and the incoming pulp thoroughly mixed with the mass of the water in the box by the partition, b, which extends across the box near the inflow end. The discharge is made by cutting the other end of the box from 2 to 3 inches lower than the sides; this overflow is made perfectly level so that the water flows out in an even sheet. The discharge pipe for the pulp is at the bottom of the box. The siphon discharge shown is the most convenient, as the aperture need not be so much contracted as if direct discharge is used; and, besides this, less fall in the mill site is required. A contracted orifice is liable to be choked up, and a smaller diameter than 1½ to 2 inches is to be deprecated.

These boxes have the advantage over the ordinary settling-pits used to retain tailings and to catch pulp for pan-amalgamation, that they do not require to be dug out, while the settling, owing to the elimination of surface currents, is more perfect. One large box of 12 feet by 6 feet at the top and 7 feet 6 inches deep is sufficient to settle the product from five or ten stamps, according to the degree of separation of water and ore required.

If the pulp is required for treatment in amalgamating pans, such settling boxes as ordinarily used do not give material of sufficiently thick consistency for the purpose. To adapt them to this, we suggest “that the pulp from the battery should be spread out and flow across a long narrow box with sloping bottom, up which the settled heavier sand is moved by scrapers attached to a revolving chain. The sand is thus scraped out of the box in a thick condition, with very little accompanying water, and joins the thickened slimes from a large spitzkasten which receives the overflow of the narrow box above it. The spitzkasten alone has been used successfully in Mexico for thickening the whole pulp sufficiently for pan-amalgamation, by the use of the Ayton intermittent discharge opening at the bottom, which is reported to deliver a pulp of less than 50 per cent, water contents. The intermittent opening allows of a comparatively large discharge orifice for the required rate of delivery, thus lessening the danger of blocking.”

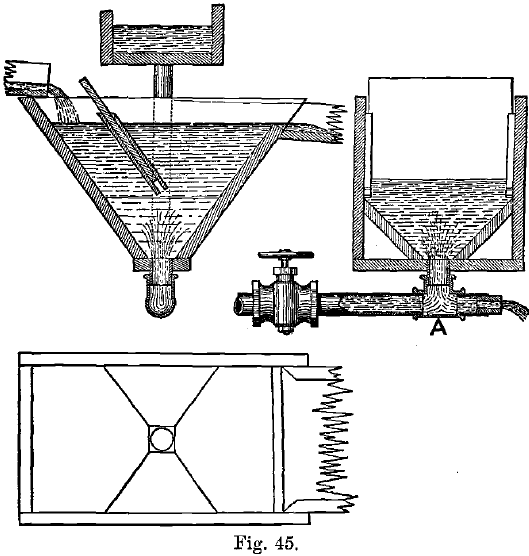

A type of Gold Settling Box introduced by Prof. P. von Rittinger in the middle of the last century for use in the Hartz, and from their shape were known as spitzkasten or pointed boxes. These boxes have the shape of inverted pyramids, the stream of unsized pulp entering at one side and flowing out at the other, whilst there is also a small discharge at the apex. The current slackening on entering the box, the heavier and larger particles in suspension at once begin to settle, and, escaping the influence of the current, fall quietly to the bottom of the box where they are discharged. In each successive box a number of approximately equal-falling particles are removed, the closeness with which the subdivision is made varying with the size of the box, and the corresponding extent to which the current carrying the pulp is checked on entering it. The larger the box the more material is collected by it, and, therefore, the more heterogeneous the particles caught. In a small box the material collected consists more nearly of truly equal-falling particles.

These equal-falling particles, however, are in any box, whatever its size may be, carried away through the aperture in the apex by muddy water containing material of all sizes down to the finest slime, and it was to eliminate this material that the ascending current was introduced. This is a current of clear water, which enters at the apex of the box (spitzlutte ) in greater quantity than can be discharged by the outflow near the same spot, so that there is an upward current of water into the box. The result is that no muddy water is discharged below, but only the particles of ore which have weight enough to drop through the ascending current, so that by regulating the strength of this, any desired class of ore can be obtained. In Fig. 45, a form is shown in which the sliding partition assists the settling, by causing the pulp to pass downwards, rapid surface currents across the box to the overflow being thus prevented. The discharge of the heavy particles is effected through A, the clear water pipe itself, by the arrangement shown. The launder above the box supplies the clear water current, and shows the head of water used, which must be kept constant to ensure uniformity of results.

The chief defect of the early forms of pyramidal boxes was that, as the area of the vat became larger and larger towards the top, the velocity of the ascending water naturally became less and less, so that many particles were able to settle down below the level of the overflow, but were stopped by the increasing force of the current, so that an accumulation of ore took place half way up the box, and ultimately became so great as to interfere with the classification. Several remedies have been devised for this defect, of which one of the simplest and most effectual is to make the box pyramidal below, but with vertical sides in the upper part. This construction is partly carried out in the box described above. A slime-pit is added to catch the stuff which is too light to settle in the boxes, in all cases in which these slimes are of sufficient value to pay for treatment. The number of boxes used depends on the number of classes of material which it is deemed advisable to make. Usually two or three classes are sufficient.