Overflow from the grinding mill runs over Gold Shaker Tables which are flat and smooth and made of a fibrous wood known as “yolombo.” They are arranged in series much the same as blanket or amalgamation plate tables. The grain of the wood in the deck runs with the flow of pulp, and a sharp-pointed tool is used to scratch its surface in a crosshatched pattern. The fibrous wood stands up along the scratches and forms an ideal trap for free gold. Twice a day the tables are cleaned and the high-grade concentrate is amalgamated by hand in a wooden batea or gold pan.

During the early days of operation referred to, nine wooden mills totaling 66 stamps, one ten-stamp California-type stamp mill, and three sand-leaching cyanide plants were in operation. Use of this equipment was discontinued.

Bumping Shaker Tables

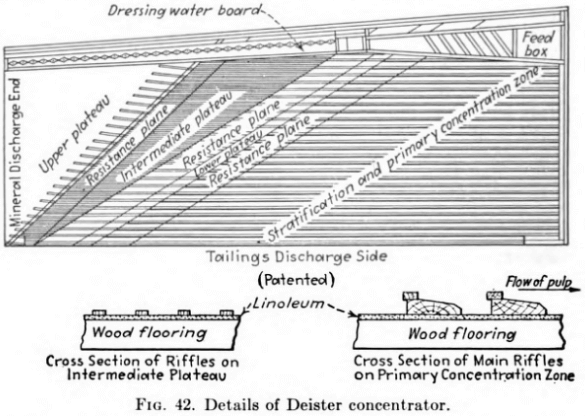

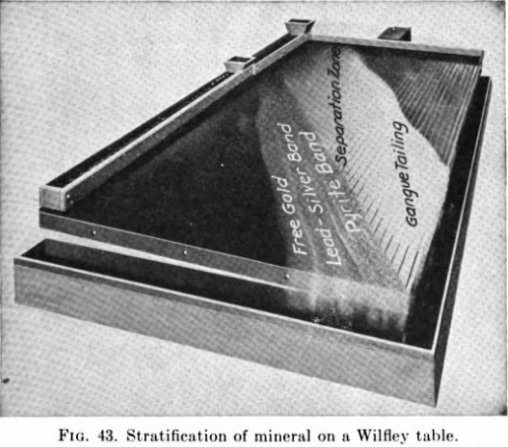

The gravity concentrators used in gold and silver milling plants are usually of the bumping-table or the endless-belt (Vanner) type. The former consists of a riffled deck carried on a supporting mechanism that permits adjustment of slide slope and connected to a “head” mechanism that imparts a rapid reciprocating motion in a direction parallel to the riffles.  A cross flow of water is provided by means of launder or other type distributors mounted along the upper side of the deck. The feed enters just ahead of the water supply, concentrate is taken off at the lower end of the table, and tailings overflow the lower side (see Figs. 42 and 43). A. M. Gaudin in “Principles of Mineral Dressing,” 1939, has in Chap. XIII made a comprehensive mathematical analysis of the principles involved in flowing film concentration and tabling. On p. 294 Gaudin states:

A cross flow of water is provided by means of launder or other type distributors mounted along the upper side of the deck. The feed enters just ahead of the water supply, concentrate is taken off at the lower end of the table, and tailings overflow the lower side (see Figs. 42 and 43). A. M. Gaudin in “Principles of Mineral Dressing,” 1939, has in Chap. XIII made a comprehensive mathematical analysis of the principles involved in flowing film concentration and tabling. On p. 294 Gaudin states:

The flowing film concentrators that are known as shaking tables utilize other principles besides those discussed so far (stationary tables). Shaking tables are provided with a reciprocating motion at right angles to the flowing fluid film and directed horizontally. This reciprocating motion of the table deck has an asymmetrical acceleration, the net effect of which is to cause intermittent travel of solids resting on the table. This is one of the auxiliary principles utilized in shaking tables.

Another auxiliary principle derives from the use of riffles which disturb the viscous flow of the fluid across the deck and substitute for it a fluid composed of one top layer flowing more or less by viscous flow and an eddying bottom layer.

Why are Riffles Important for Tabling

They are responsible for the increased capacity of riffled decks over smooth ones. This is realized when it is considered that a smooth deck treats a bed one particle deep and a riffled deck treats a teetering suspension of particles often many particles deep. Each trough between successive riffles is a place where hindered settling and consolidated trickling occur.

The capacity of tables varies widely between a maximum of, perhaps. 200 tons per 24 hr. in coarse roughing operations to 5 to 10 tons per 24 hr, on very fine feeds. Around 10 mesh is about the upper practical size of feed, while only incomplete recoveries are made in the 200 to 325 mesh range. Finer material is lost on all but very low-capacity slime tables.

Vanner Gold Shaking Table

The endless-belt or Vanner type of table was developed for the purpose of recovering the fine mineral particles lost in ordinary table operation. With a feed range of minus 65 to 100 mesh, particles as fine as 10 to 20 microns are recovered, but the capacity of such tables is only 1 to 3 tons per 24 hr., and the vanner is now practically obsolete.

Tables can be operated on either classified (sized) or unclassified feed. The use of an unsized feed, particularly in roughing operations, as at Hollinger, is common practice, but it is generally recognized that preliminary sizing of the feed with each sized band going to a separate table is the more efficient practice.

A. W. Fahrenwald concludes that preliminary classification, particularly if classifiers of the hydraulic types are used, gives increased recovery, a higher grade concentrate, greater table capacity, and less middling for regrind; in other words, classification enables a table to do its best work.