The gold to be parted must be approximately free from base metals, particularly from those which are not soluble in nitric acid, such as tin, arsenic, antimony. If these were present they would form insoluble oxides, which would remain with the gold, so that further refining operations would be necessary: they would, moreover, cause a great increase in the consumption of nitric acid, so, if they are present, the gold is freed from them as far as possible by melting with nitre. Copper, lead, and other metals which are readily soluble in nitric acid are less obnoxious, and small percentages of these are allowed to remain, as they are not difficult to separate from the silver when in solution with it, while the presence of copper in particular is advantageous in promoting rapid dissolution of the alloy. If present in large quantities, however, even these metals would create difficulties and expense, increasing the consumption of acid.

The gold to be parted must be approximately free from base metals, particularly from those which are not soluble in nitric acid, such as tin, arsenic, antimony. If these were present they would form insoluble oxides, which would remain with the gold, so that further refining operations would be necessary: they would, moreover, cause a great increase in the consumption of nitric acid, so, if they are present, the gold is freed from them as far as possible by melting with nitre. Copper, lead, and other metals which are readily soluble in nitric acid are less obnoxious, and small percentages of these are allowed to remain, as they are not difficult to separate from the silver when in solution with it, while the presence of copper in particular is advantageous in promoting rapid dissolution of the alloy. If present in large quantities, however, even these metals would create difficulties and expense, increasing the consumption of acid.

The bars are melted together to form an alloy which, it was formerly believed, must contain one part of gold to three parts of silver (hence the term “ inquartation ” applied to this process). In most refineries, however, the proportion of silver used is less, the minimum being 1¾ parts of silver to one of gold. At the Philadelphia Mint, the proportion is now 2 1/3 to 1. Dore bars containing small quantities of gold are, of course, preferred to bars of fine silver for the purpose of alloying with the argentiferous gold bars. After the “ inquarted ” alloy has been thoroughly mixed by being stirred while still in the furnace, the metal is poured into copper tanks filled with cold water, which is sometimes kept cool by ice, while, in some refineries, a stream of water is kept constantly flowing through the tank. The metal is poured with a circular and wavy motion in a thin stream to prevent the formation of lumps; leafy granules and small hollow spheres are thus formed. The pouring is done either from a crucible or from a ladle, the vessel being filled from the large crucible by dipping, and held about 3 feet above the surface of the water. In the tank is a perforated copper pan, which is lifted out when the pouring is completed, and the granulations allowed to drain.

Dissolving the Granulations

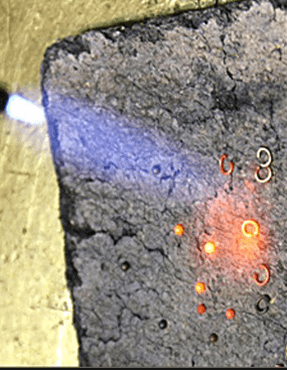

The granulated metal is heated with nitric acid in cylindrical vessels of earthenware, porcelain, or platinum. The pore lain vessels in use at the Philadelphia Mint have a capacity of about 33 gallons, and contain 2,080 ozs. of granulations: twelve such vessels are placed together on a lattice work of wood, which is laid on the bottom of lead tanks, and are surrounded by water 10 inches deep kept at the boiling temperature by means of steam. The earthenware vessels are covered by a closely-fitting lid provided with a delivery tube to carry away the fumes. Messrs. Johnson & Matthey’s platinum vessels, which hold 800 ozs. of metal, are heated by separate furnaces, the fuel being coke or coal gas.

The strength of the acid used varies from that of specific gravity 1.41 to that of specific gravity 1.2. When nitric acid alone is used, about 3 lbs. of acid (sp. gr. 1.2) are used to dissolve each pound of granulations, but of this quantity the amount used in the last boiling (about 20 per cent, of the whole) is available for further use; more acid is required if there is much copper present. The first addition of acid is of about 1½ lbs. to each pound of metal ; it is kept boiling gently for about five or six hours, by which time most of the silver will have been dissolved.

The solution is allowed time to settle, and the hot supernatant liquid is siphoned off by a gold or glass siphon, and diluted with water to prevent the formation of crystals on cooling. The second addition consists, in some establishments, of strong acid (sp. gr. 1.414), and in others of acid of the same strength as before. The second boiling is for two or three hours only, and the third boiling for only one or two hours, the liquid being siphoned off after each boiling.

The vessels are provided with hoods and small chambers in the delivery tubes, in order to effect a partial condensation of the acid, and also to recover the small amount of silver nitrate which is carried over mechanically, owing to the violence of the disengagement of gas bubbles. The fumes are conducted to the melting furnace where they are consumed, giving up their oxygen to the fuel.

The reactions that occur are partially expressed by the following equations:

6Ag + 8HNO3 = 6AgNO3 + 2NO + 4H2O

3Cu + 8HNO3 = 3Cu(NO3)2 + 2NO + 4H2O

4Zn + 10HNO3 = 4Zn(NO3)2 + N2O + 5H2O

and similar reactions for other metals. The amount of nitrous oxide evolved increases towards the end of the operation. It is seen that silver decomposes less than its own weight of nitric acid, while copper and zinc destroy nearly three times their weight of the acid. Nitric acid of specific gravity 1.2 contains about 32 per cent, of anhydrous HNO3, so that the quantity of acid of this strength theoretically required to dissolve 1 lb. of silver, copper, and zinc is about 2.4 lbs., 8.3 lbs., and 7.6 lbs. respectively.