To perform Gravity separation of heavy minerals in the range 600 microns to 12 microns and to simulate gravity recovery performance on a sample hoping recovery and grade achieved can by higher than in plant operation, will let you analyze the grade/recovery curves permitting a relative assessment of performance.

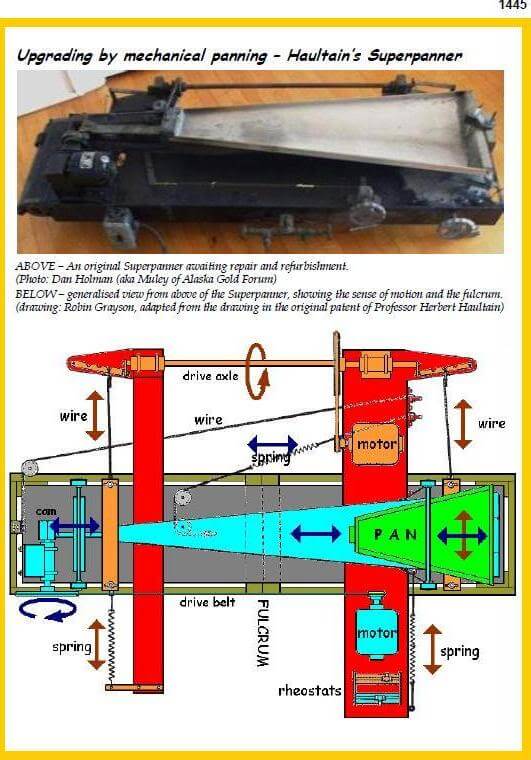

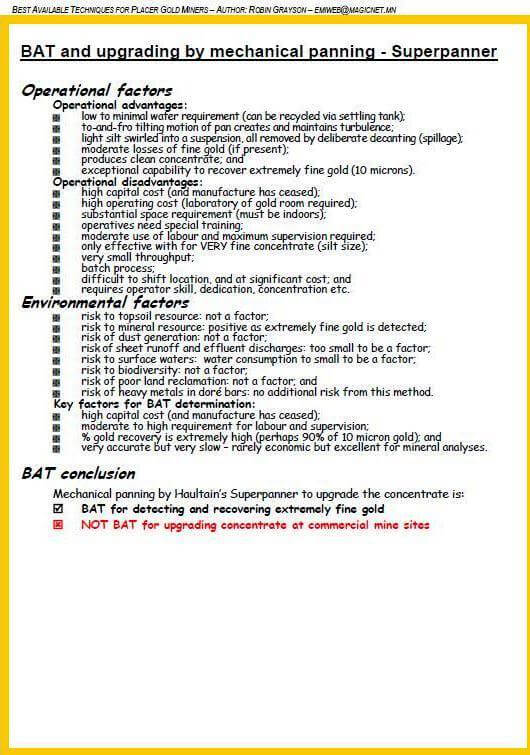

You will use a superpanner as it is a completely integrated machine which only needs suction lines to draw off concentrate tailings. The superpanner can simulate the hard knocking action of a shaking table or the gentle washing of a panner.

Sample Preparation of Individual sized fractions:

Micron

– 600 +212

-212 +106

-106 +75

-75 +38

-38 +12

The –38 + 12 micron fraction is obtained through cyclosizing.

Procedure

A 50 gram maximum of sample is recommended for the U-shaped deck of the superpanner. The superpanner itself has the ability to rock sideways and tilt in the horizontal. The knock that is applied to the end of the deck is like all other motions in that the degree of motion needed can be varied. The speed of the motion sideways and the interval of the knock can also be controlled. It is very important that water additions throughout the separation are such that the solids are kept in solution and that dry beds do not appear, thus hindering separation. Normally the deck starts in the horizontal with a hard fast knock and no side motion. It is hoped by this arrangement that the heavy mineral will fall through the sample onto the bottom of the deck (much like a jig).

After a period of time the knock is taken off and the deck angled towards the tail pipe and a gentle sideways motion is applied to remove the gangue from the top of the heavy mineral.

Once the heavy mineral is separated from the remainder of the sample it can collected into the concentrate holding bottle by means of the vacuum system. Tailing are normally taken off throughout the separation and re-superpanned several times. This enables production of a rougher concentrate with the final tail free of liberated cassiterite. The rougher concentrate can then be put back on the deck and a super concentrate of the highest possible grade removed (minimum weight – approximately 0.2g). Subsequently the remaining rougher concentrate may be re-superpanned and spread out along the deck of the superpanner where it can be split into three separate concentrates depending on S.G. (that is the proximity to the concentrate end of the deck). In the finer fractions it should be possible to attain the liberation size of the heavy mineral and recovery should hence be high. In the coarser fractions, however, high recovery is not always obtained because of unliberated cassiterite.

Note: High recovery and grade can only be achieved if the heavy mineral is liberated. The ability to quickly visually identify the heavy mineral and considerable operator patience are important attributes for high recovery.

Learn more about it at https://bb.bbboy.net/alaskagoldforum-print?forum=2&thread=37

|

|