In preparing a sample of refined lead for analysis, it is necessary to exercise great care to avoid contamination, as the amounts of the various impurities present in market lead are very small.

The lead is cut into convenient-sized pieces, which are flattened out with a hammer, so that, on putting the lead through the rolls, strips of about one inch in width and 1/32 in. in thickness are obtained. The hammer, anvil, and rolls should be carefully cleaned before use. The strips of lead are cut up into pieces of about one inch square. If the lead is rolled out very thin and cut up into small pieces there is considerable risk of the acid acting too violently and causing loss through frothing over. A blank assay on all the reagents used should be carried right through, along with the actual analysis of the lead. This is of the greatest importance, particularly with regard to the determination of such impurities as iron, sulphur, arsenic, and antimony.

LEAD ANALYSIS METHOD

The method of analysis is as follows:—Take two lots of 600 grm. each, place in a large beaker, add 2000 cc. distilled water and 750 cc. concentrated HNO3. Cover with a clock glass and warm on a hot asbestos plate until all action ceases. (If any white precipitate forms, filter off and examine for Sn and Sb.) Add 420 cc. H2SO4 (1-1), and stir well while adding the acid. Allow PbSO4 to settle, pour off the clear liquid into a 12-in. porcelain evaporating dish, and start evaporating down, the dish being placed directly on an 8-in. ring gas burner. Wash the precipitate three times by decantation, using approximately 1200 cc. hot water for each washing, and stir well each time. Filter through filter paper on a 6-in. glass funnel, then pass the whole of the precipitate on to the filter paper, wash three times, and allow to drain. Gradually add the washings to the main bulk of solution in the dish. Evaporate right down to fumes, leaving not more than 10 cc. of solution. Cool, add 50 cc. cold water, heat gently to boiling for 10 min., and then add 2 grm. tartaric acid. Wash down the sides of the dish with a jet of hot water, then filter and wash three times. Re-treat the PbSO4 by washing it out of the filter paper into 300-cc. beakers, pour off the liquid through the same filter, then boil up with 15 cc. strong HCl and a small amount of KClO3 until the PbSO4 is broken up. Add 10 cc. concentrated H2SO4, fume, cool, dilute, add 1 grm. of tartaric acid, boil, and filter into the first filtrate. Re-treat the PbSO4 in the same way a second time, and filter into the beaker containing the last two filtrates. The bulk of the solution is now about 400 cc. Add 10 cc. strong HCl, warm on the asbestos plate, and pass a rapid current of H2S for 45 min. Allow to stand in a warm place overnight. In the morning again pass H2S for 15 min., then filter and wash with H2S water. The filtrate contains -Zn, Cd, NI, Fe, and traces of Pb (filtrate 1). Precipitate contains Cu, Bi, As, Sb, and Pb (precipitate 1). Wash precipitate back into the 400-cc. cylindrical beaker containing a few crystals of tartaric acid and dissolve any precipitate adhering to the filter paper with hot HNO3 (1-1). Add NaOH until alkaline, and then add 15 cc. Na2S solution (250 grm. dissolved in 500 cc. water). Make bulk up to 200 cc., allow to stand in a warm place for 10 min. filter and wash with warm water containing a little Na2S.

Filtrate from Na2S Treatment—Make acid with HCl, add 10 cc. in excess, pass H2S into the hot solution for 10 min. and allow to settle for two hours. Filter and wash twice with H2S water. Wash the precipitate back into the same beaker and dissolve any adhering to the filter paper with a little hot dilute NaOH solution. Add 20 cc, of HCl (if the bulk is kept low enough, this amount of acid will be sufficient), 1 grm. of KClO3, and heat carefully until the Sb and As are in solution, and some sulphur separates. Add 0.5 grm. tartaric acid, filter and wash with hot water several times, keeping the bulk of the solution as low as possible. Arsenic—Cool, make alkaline with NH4 OH, add 20 cc. “ magnesia mixture,” then one-tenth of its bulk of NH4OH, allow to stand in a cool place for two hours, stirring well at frequent intervals. Allow to stand for one hour more, and then filter through a small weighed Gooch crucible containing an asbestos wad. Wash with NH4OH water, dry in hot-air oven, then heat in a muffle at a red heat for 15 min. Cool and weigh as Mg2As2O7 ( x 0.4838 = As).

Filtrate from Mg2As2O .—Boil until most of the NH4OH is expelled. Make acid with concentrated HCl and add 10 cc. in excess. Boil for 20 min. to expel any chlorine. Antimony—Pass H2S through the warm solution for 30 min., allow to settle in a warm place, and filter onto a weighed Gooch crucible. Wash several times with warm water. Heat in an atmosphere of CO2, raising the temperature gradually, and keep for 20 min. at a temperature of 270° C. Cool to 100° C. in CO2, and finally in a desiccator. Weigh as Sb2S3. ( x 0.7146 = Sb.)

Precipitate from Na2S Treatment.—Dissolve off the filter paper with warm HNO3 (1-1), then add 7 cc. concentrated H2SO4, and take to strong fumes. Cool, dilute to 100 cc., filter, and wash with cold water containing a little HS2O4. This separates the last traces of Pb. Bismuth—Pass H2S for 15 min. into the hot filtrate, allow the precipitate to settle, filter, and wash with H2S water. Re-dissolve the precipitate back into the beaker with warm HNO3 (1-1), heat until all is decomposed, then add 2 drops of HCl and stand in a warm place until the AgCl settles out. Filter, make filtrate alkaline with NH4OH, and boil. Add 15 cc. (NH4)2CO3 solution (10 %), bring to the boil again, and allow to settle for 20 min. Filter through a weighed Gooch crucible, wash with hot water, dry, heat in a muffle to dull redness for 5 min., cool, and weigh as Bi2O3 (x 0.8965 = Bi.)

Filtrate from the Bismuth.—Make acid with HCl, boil, pass H2S to precipitate the Cu, allow precipitate to settle, then filter and wash with H2S water. Copper—Dry the precipitate and ignite it carefully over a Bunsen burner in a small porcelain crucible. Add 2 cc. strong HNO3, evaporate down to 0.5 cc., dilute with a little cold water, and add NH4OH until alkaline. Filter into a larger white porcelain crucible (No. 2) through a small filter paper. Add to the blank assay, containing the same amount of reagents, a standard solution of copper nitrate until the two blue shades are matched. (1 cc. Cu(NO3)2 = 0.0005 grm. Cu.)

Filtrate 1, containing Cd, Fe, Zn, Ni.—Make both assay solutions and the blank assay alkaline with NH4OH and pass H2S for 15 min., allow to settle for 10 min., then filter, but do not wash. Re-dissolve the precipitate off the filter paper with 10 cc. HNO3 (1-1), boil until all is decomposed, add 6 cc. H2SO4, take to fumes, cool, dilute and filter, washing with cold water. This removes the last traces of Pb.

Cadmium—Make bulk up to 200 cc., heat to boiling, and pass a rapid current of H2S for 20 min. to precipitate Cd. Filter and wash. If much Cd is present, re-dissolve the precipitate in 10 cc. warm HCl (1-1), take to fumes with 6 cc. H2SO4, cool, make bulk up to 200 cc., and reprecipitate the CdS. Dissolve the precipitate off the filter paper with hot HCl (1-1) into a weighed platinum dish, add 5 drops of H2SO4, take to dryness, and heat carefully over a small Bunsen flame until all fumes cease. Cool in a dessicator, and weigh at CdSO4. ( x 0.539 = Cd.)

Filtrates from Cd.—Add NH4OH until alkaline and pass H2S for 10 min. Allow to settle, and then filter, but do not wash. Re-dissolve the precipitate off the filter with hot HNO3 (1-1), and warm until all is decomposed. Iron—Add 1 grm. of NH4Cl, and then NH4OH until alkaline, boil, settle, and filter. Re-dissolve the precipitate with HCl, re-precipitate with NH4OH, and filter into the first filtrate. Dissolve the precipitate with HCl, reduce with SnCl2, add HgCl2 in excess, and titrate with standard K2Cr2O7 solution. (1 cc. = 0.00475 grm. Fe.)

The filtrate from the Fe contains Zn and Ni, if present in the sample. Pass H2S, and while the H2S is passing add 6 drops of ferric chloride solution (10 %). Allow the precipitate to settle, filter, re-dissolve the precipitate with 10 cc. HNO3 (1-1), and boil until all the precipitate is decomposed. Zinc—Now continue with both assay and blank by adding 5 grm. of cream of tartar, 2 grm. NH4Cl, and make alkaline with NH4OH, then add 0.5 cc. in excess in a bulk of 150 cc. Titrate at 70° C. with standard dilute K4FeC6N6 solution (1 cc. = 0.002 grm. Zn), using glacial acetic acid as outside indicator.

Note.—The blank assay is started off by placing 750 cc. concentrated HNO3 and 210 cc. concentrated H2SO4 in the 12-in. porcelain basin and evaporating it down along with the assays. It is then taken right -through all the estimations given above, in the same manner as the assays.

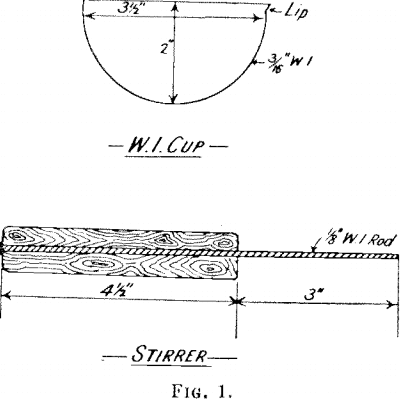

Sulphur.—Weigh out two lots of 500 grm. each of the rolled lead, cut into small pieces.. Heat three wrought-iron pots over a Bunsen flame, fitting each pot into a hole in a piece of asbestos board. Place in each pot 40 grm. of NaOH. (Take a fresh bottle of NaOH ; break the NaOH up quickly into small pieces in a porcelain mortar and mix it up well.) When the NaOH is molten, add the lead piece by piece until all is melted, stirring well all the time. In one of the pots run a blank charge, using some lead which has been treated several times with NaOH as described above. Keep molten for 15 min., stirring well all the time. Cool, and extract with hot water, decanting into a 600-cc. beaker. Add 20 cc. bromine water and allow to stand for a quarter of an hour on a warm asbestos plate, then make acid with HCl and boil of Br. Filter and wash with warm water. Heat filtrate to boiling and add BaCl2 solution. Boil, and then allow to settle in a warm place overnight. Filter, wash the precipitate well with hot water. Dry, ignite, and weigh as BaSO4 (x 0.1373 = S.)

Silver—Triplicate assays of 3 A.T. each are cupelled directly in large cupels.

Gold.—If the lead is to be tried for gold, or, in the case of a lead very low in silver, duplicate assays of 36 A.T. each are scorified, using 6 scorifiers (3½-in.) for each assay. The six lead buttons, when sufficiently small, being combined, cupelled together, and the silver prills weighed. The two prills are then parted with HNO3, and any gold determined. The amount of gold present in refined lead is generally so small that it is often necessary to take larger quantities of the sample for the estimation.

Note.—When nickel is present, proceed in the following manner :— After precipitating the iron, make the filtrate slightly acid with HCl, then add NH4Cl and enough NH4OH to make it slightly ammoniacal.

Nickel—No precipitate will be formed if sufficient NH4Cl has been added. The solution is then just acidified with HCl, heated to boiling, and the nickel precipitated with an alcoholic 1 % dimethylglyoxime solution, boiled for a few minutes, and allowed to settle. While still hot the precipitate is filtered into a weighed Gooch crucible, washed with warm water, and dried at 110° C. for 45 min. (20.31% of the precipitate is Ni.) The filtrate is made slightly acid with acetic acid and H2S passed to saturation. The precipitate is filtered off, washed with H2S water, then dissolved in 10 cc. HNO3 (1-1), and the solution is ready for the determination of Zn.

Manganese is not likely to be present in a refined lead.

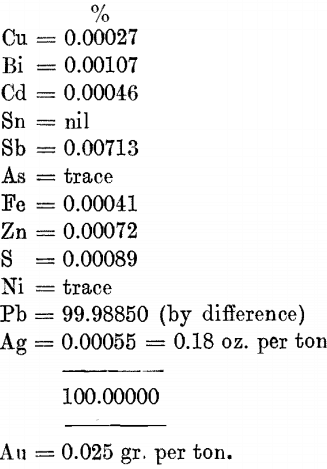

TYPICAL ANALYSIS OF A MARKET LEAD