To start with I will give you a simplified description of how selective froth flotation works, lets start over again with a description of the equipment and why it works.

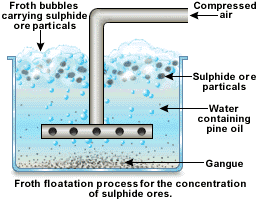

When the grinding circuit is finished with the ore it will be ground very fine and the density of the slurry will be between 30% to 45% solids. This is very important because the slurry will be treated chemically and air will be passed through it. As the air bubbles come into contact with the chemically treated ore, the mineral will stick to the air bubble and be lifted off. If the density of the slurry is too heavy the air bubble will not be able to form properly, and the chemical will not be mixed properly throughout the ore. If the density is too light, some of the chemicals, which by the way, are referred to as reagents, will not be as effective due to dilution.

To be able to retrieve the mineral, the ore must come into contact with the air bubbles so that the minerals may attach themselves to those bubble. Too much water will increase the volume of the slurry. If the volume is increased the retention time of the slurry is lowered. The result is an increased chance that some of the mineral will not make contact with an air bubble that has vacant space on it.

To be able to accomplish this process requires certain things to happen. First the mineral must remain in suspension.

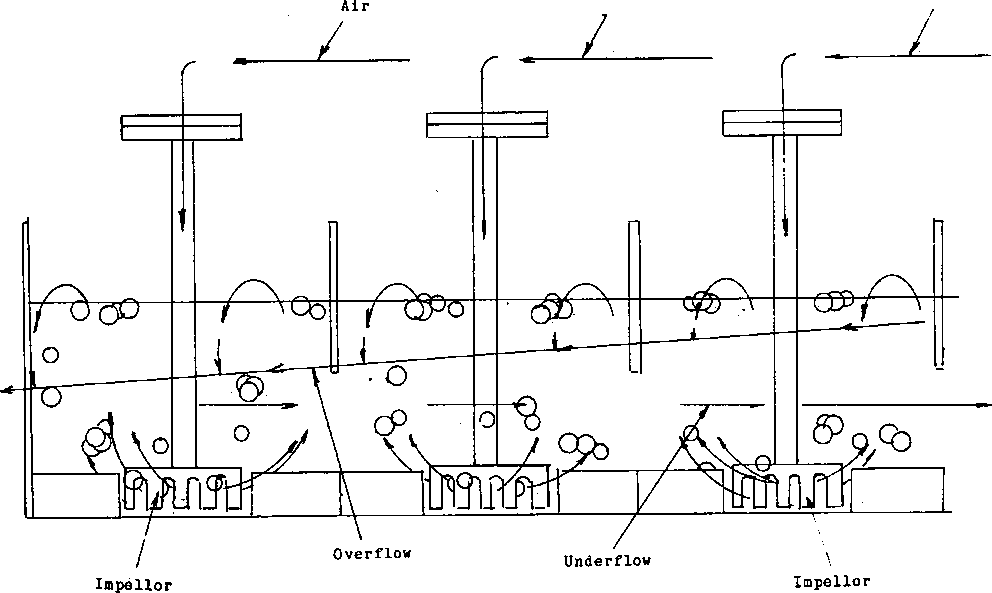

This means that it cannot be allowed to settle. The air must be regulated so it will form individual bubbles, not a steady stream. Also the better it is dispersed through the slurry the more of a chance it has of coming into contact with the mineral. And finally there must be enough retention time for all of this to happen. To create the needed space and effects, Flotation cells have been developed.

Here is a page about the invention of froth flotation as it appeared in a 1917 edition of the Popular Mechanics detailing how it works.

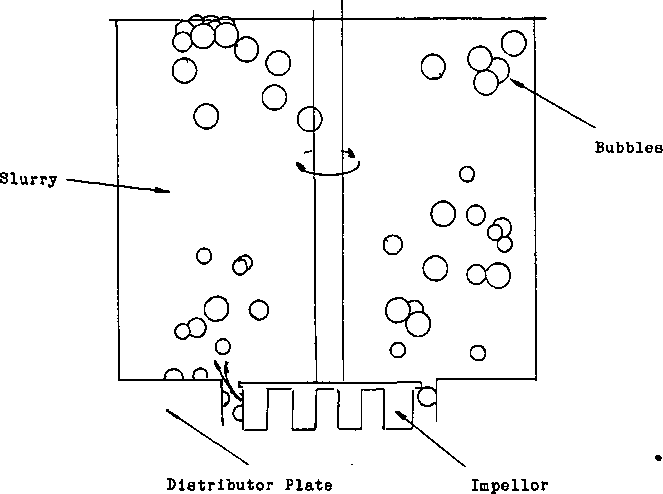

Each cell has an impeller, this rotates and acts like a giant mixer. Its purpose is to keep the ore in suspension, provide a passage to allow the air access to mineral, and help distribute the air through the cell. If we look at a cut away diagram of a cell we can see how they work.

|

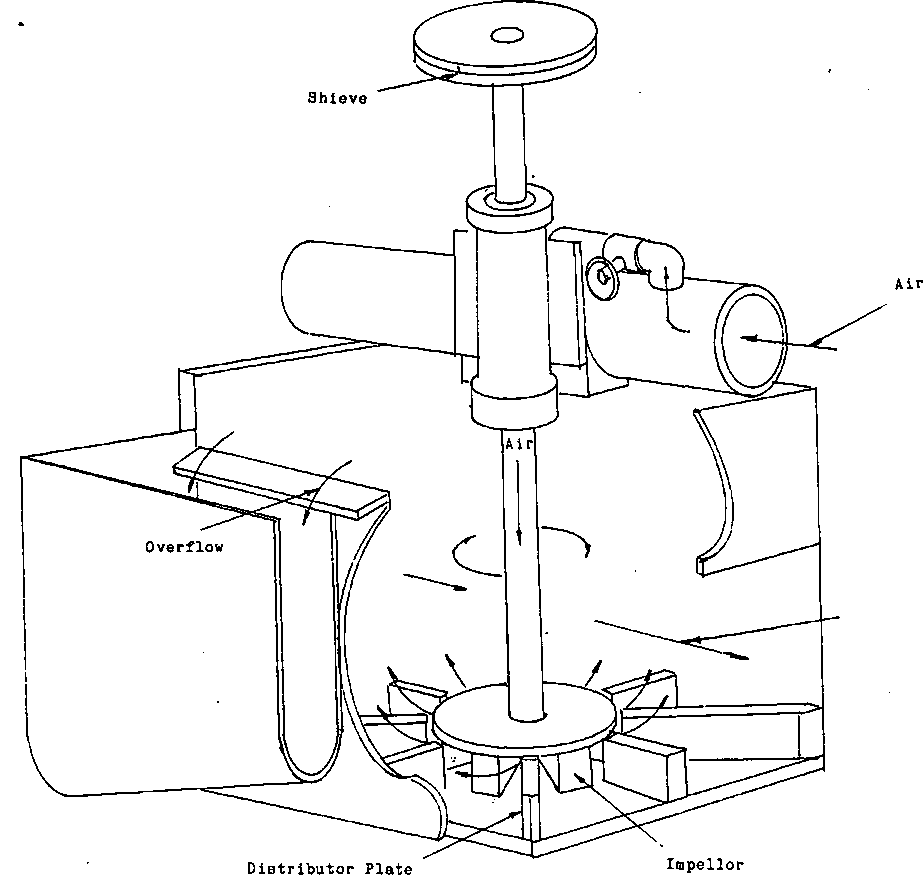

At the top of the impeller shaft is the SHEAVE, this is a drive pulley for V-Belts. The shaft is supported by two bearings in a housing. At the bottom of the shaft is the impeller. To ensure that the air reaches every corner of the cell there is a distributor plate that the impeller sits in.

As the impeller turns the air is injected through the blades on the impeller which in turn will force the air out through the vanes of the distributor plate. This will break the air stream up into bubbles. The vanes on the distributor plate will also guide the air bubbles to all portions of the cell. As the bubble rises to the surface, the ore will attach itself to it. When it reaches the surface of the cell the bubble will become part of a FROTH COLUMN. The top of this column will extend beyond the top edge of the cell, therefore it will flow over the edge carrying the mineral with it. The waste material, that portion of the slurry that wasn’t attracted to the bubble will flow through the cell to eventually be discarded.

That is the basic design of a single froth flotation cell and how it works. To be successful in the recovery process, several of these cells placed one after another will be required to provide the necessary flotation time required to recover the amount of mineral present.

There are several different cell designs, each one a little different, depending on the job that they are doing. There may be froth partitions to control the flow of froth, or there may be cell partitions if the retention time has to be increased. The impeller and distributor plate may change design if the different bubble characteristics are required and of course the size of the cell will change to the volume of material being floated

Now that you know how an individual flotation cell works, let’ see how the chemicals effect the ore so that a separation will take place. Mining reagent-s are broken down into categories.