The main idea in collecting the information you’ll find in the following discussion was to help you, as a flotation machine operator. Regardless of how much or how little you know about it, the ideas you’ll find here can help you do a better job, if you want them to.

Naturally your company is anxious to have you improve your work, because a lot depends on how well you handle those machines; but don’t think that that’s the only reason why you ought to do better. The big reason, for you, is that the more skillful you become, the easier it will be for you. The fellows who are always in a jam and working their heads off all shift are also the ones who don’t know what it’s all about. The good operators see trouble coming and prepare for it and for that reason they don’t often get into trouble. The job is easier for them because they know how to do it. We want to try to make it easier for you, too.

Because we don’t know how familiar you already are with the flotation process, we’ll have to assume that you are starting about from scratch. Well the first thing you ought to learn is how the process works and what it is that you are trying to do. We’ll leave the chemistry of flotation out of it though, because it doesn’t much matter to you why the thing works so long as it does work, and, frankly, the subject is too deep for us.

How the Flotation Process Works

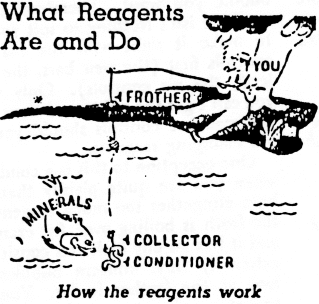

The plain facts are that in the pulp as it comes to you from the ball mill circuit is a small quantity, generally a few percent, of a mineral your company expects you to get out. To do this, you will add to the pulp one or more chemical reagents that have the property of combining with the valuable mineral in such a way that these particles of ore can no longer be wetted by water. These reagents do not combine with the waste rock particles, and therefore the latter can still be wetted. Suppose you arc working with a galena ore. After you have put in the proper reagents, if you could take a piece of galena out of the pulp and magnify it, you would see that water rolls off the galena as it would off a duck.

Then when the pulp goes to the flotation machines, you add another reagent that creates a froth in the pulp. That is, the reagent helps form millions of air bubbles that are circulated all through the pulp by the action of the machine. Whenever one of these bubbles hits an ore particle that is not wetted by water it sticks to that particle, and before long there are many such mineral particles sticking to each bubble. None of the bubbles will stick to the waste material. The result is that these air bubbles collect on the surface of the pulp in the machine to form a froth, and all you have to do is see that this froth spills over the side into the proper launder. The valuable mineral is now in the launder, and the waste rock is going down the tailing flame— you hope.

All you have to do is to see to it that enough of these reagents is added, but not too much, and that the machines are working properly. That doesn’t sound like much of a job, but, believe us, it’s an art. The thing for you to do if you want to be really good at it, is to ask a lot of questions of people you can count on as knowing the answer. Don’t be afraid of asking “fool” questions. The mill superintendent and the metallurgist and the shift boss would a lot rather have you ask questions of them and find out how to do the job right, than to have you keep still and do the job wrong.

Let’s have a word or two about those reagents.

There are three classes of flotation reagents in general: conditioners, collectors, and frothers. Conditioners are those reagents that are added to the pulp to help the other reagents do a better job. That definition covers a multitude of sins, and we haven’t space to take up all of them. To list a few conditioners, there are: lime, copper sulphate, soda ash, sodium silicate. Aerosol, and several more. Each of them has a specific job, and it is up to you to learn what it is for the one you are using.

Lime

Take lime, for example, which is generally used in flotation to keep pyrite from floating and to adjust the pH of the circuit. What’s pH? Just a flashy term for a convenient way of telling how much acid or alkali there is in the flotation pulp. A pH of 7 means that the pulp is neither acid nor alkaline: above the pulp is alkaline, below 7 it is acid. Lime makes the pulp more alkaline, resulting in a pH of 8, 9. 10. or so depending on how much you add. In some mills, this matter of pH is tremendously important and it will pay you big dividends in easy operation if you pay attention and keep the pH where it belongs.

Flotation Collectors

Collectors are the reagents that catch hold of the mineral you’re after. The xanthates. thiocarbanilide several of the Aerofloat reagents, thiophosphates, Hydroxamate; all are collectors. If you don’t add enough of whichever one of these you’re using, the company loses money fast, and you’ll have words with the shifter tomorrow when the assay sheet comes around. Of course, if you are working in a mill where the metallurgist sets the reagent feed rates, the buck is automatically passed.

Frothers

Frothers are the reagents that make the bubbles that lift the mineral out of the pulp. Pine oil, fatty acid, MIBC and several other numbered reagents are the most commonly used frothers. Their action is simple. More frothcr, more bubbles. Less frother, fewer bubbles. Don’t ever drop a bucketful of pine oil into the flotation machine feed box unless you’re tired of working there.

Only three or four of these reagents are being used in your plant. Your job is to find out for sure exactly what each of them is for in your operation. Don’t go by what somebody said he heard somebody say the fellow that grinds samples in the assay office said. Buttonhole the metallurgist, if he hasn’t already told you, and make him tell you what the reagents are supposed to do. Better still, ask him to put it in writing, or you write it down as he tells you. We know from experience that some flotation operators have ideas about the reagents they are using that would give the mill superintendent the shock of his life if he knew about it. That isn’t the operators’ fault. Nobody had ever told them the facts of life. Don’t you be like that.

Know Your Flotation Machine

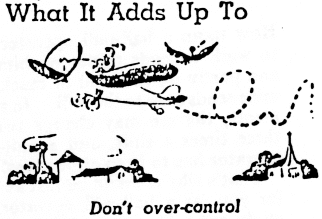

Now, to get right down to the actual operation, what are the elements with which you have to work? First, of course, are the reagents we mentioned before, and with regard to them we can only repeat our advice to find out as much as you can about how they work. Also, if you are permitted to adjust the reagent feeders yourself, go easy with them. Don’t be rushing up every ten minutes to add more xanthate or cut down the pine oil a drop or two. By the time you have made some such small change, the pulp conditions may have changed a little, and you ll simply wear yourself out trying to catch up with conditions that stay one jump ahead of you. Don’t over-control.

Aside from the reagents, you have the machine controls to work with. These arc different with different makes of machine, but, in general, they are: the tail gate at the end of each bank of cells; weirs placed in some makes between each cell; weir bars placed along the lip in each cell over which the froth flows: other types of adjustable partitions between cells: and, in some makes, a valve that controls the air admitted to each cell.

In general, you will make up your mind about how to control the machine and the reagents In the appearance of the froth coming out of the machine. We could go on here for several pages describing what a flotation froth ought to look like for all the different kinds of minerals that are now being floated, but you’d be interested in only a small part of all that. Here, again, the best thing you can do is get somebody who knows to tell you when the froth in the rougher cells and the cleaner cells looks the way it ought to look. Then you take a good long look at it and try to keep it that way when you’re running the machines.

Flotation Froth

There are, however, certain characteristics that apply to most flotation froths. The bubbles in the froth from a cleaner cell, or from the first couple of cells in a rougher section, should be fairly large, say an inch or so across, and they should be well loaded with mineral and should break down easily when they drop into the launder. If you look at them closely, you will see in the center of each bubble a thin spot that is almost clear, like a little window, and the surface of the bubble will have a slightly watery shine on it as though it were actually wet. These “windows” and this watery look are, in most cases, a good sign. They mean that the bubble is neither too tough nor too brittle, and that there is a draining action going on along the surface of the bubble that allows waste mineral, shoved up accidentally by the bubble, to drain back into the pulp, where it belongs.

The froth in the rest of the rougher cells should, in most cases, look quite different. The bubbles are smaller, more like the head on a stein of beer, and they don’t carry as much mineral. Also, the froth in the roughers spills over faster; in fact, the rougher cells are spoken of as “running faster.” Here you don’t have to worry about waste draining back into the pulp: the main idea is to get the ore mineral out fast.

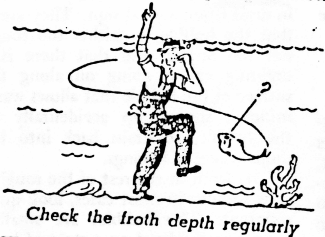

Watch the froth constantly, then, and learn from it but don’t stop with just watching it. You can’t be sure of what that froth is carrying unless you really break it down and see. Mill- men who sweep their hands across the froth in a cell and then tell you exactly what’s in it may be kidding themselves and you too. There ought to be a white-enameled vanning plaque kept down in the mill at all times, and you ought to learn to use it properly. We can’t describe in words how to handle a vanning plaque, because its use requires a peculiar combination of motions that defies description, but with a little , practice and advice from someone who knows, you’ll get it all right. Then when you take a little froth on the vanning plaque, and break it down, and spread it out, you’ll see exactly what minerals are being carried by the froth, and, more important, how much of each mineral, if you do that long enough, you’ll be able eventually to forecast pretty accurately about what the concentrate will run when it is assayed. A vanning plaque is the best single tool you can have in the mill to help you decide how the machines should be operated. Another little gadget that is not so important but which is handy, nevertheless, is a froth-depth indicator.

This is simply a wood slab about a foot square and 2-in. thick, in the center of one side of which is fixed a 1 x 1 inch stick and about 18 inches long. The stick must be set perpendicularly to the slab. Set the slab in the classifier or the feed box or some place where the pulp is the same density that it is in the machine, and let it float for a moment. Then measure up from the watermark and mark the stick off in inches and halves. Then to measure the froth depth in the cell, drop the slab into the cell, let it float, and read the depth at the mark nearest the froth surface. This comes in handy because it is sometimes necessary to control the froth depth pretty closely (deeper on cleaners, thinner froth on roughers), and this indicator is the simplest way we can think of to measure froth depth accurately.

One of the best ways of keeping track of what’s going on in the machine is to keep a little log of the things you observe and to note down in it the assays of the samples that were taken during that time. Did the froth look dry and tough during most of the last shift? Note it in your book, then see how the assays compare with those corresponding to other froth conditions. You can learn best by experience, and a written record of that experience is a far more reliable guide than your memory, however good your memory may be.

The thing that makes a man a really good flotation operator is his ability to see trouble coming and to avoid it. A good man watches what’s going on and runs the machines instead of letting them run him. For example, by noticing little changes in the froth conditions or the pH of the pulp a man can sometimes get a warning of an approaching change in the kind of ore coming into the mill. To treat this different type of ore, he may have to use more lime or more frother or he may have to change the adjustment of the machines. Whatever he has to do, the main point is that by the time the change in ore actually arrives, he is ready for it.

A poor operator, on the other hand, usually gets caught flat-footed by such changes. He catches on only when the froth drops altogether, or begins pouring over, as the case may be, and he has to spend the next hour or so in a sweat trying to straighten things out. Then just about the time he’s off rolling a cigarette and telling the shifter, “Well, I got that licked,” the ore changes again, the froth goes hay¬wire, and our friend is right back in the deep hot grease. By the end of the shift, he’s usually run ragged, and the tailing assay for his shift is higher than a kite. He just works too hard.

As we have already noted, the kind of froth you get and the amount of mineral it carries depend pretty much on the reagents you add. The machine controls, however, determine the rate at which the froth comes off the cells. To run a machine “faster” —that is, to make more froth spill over—you raise the pulp level, lower the froth lips, or let in more air. To run the machines “slower”—that is, to cut back on the amount of froth— you simply reverse these things.

You can also speed up or slow down the amount of froth coming off by changing the amount of frother added, but remember, it is better not to. In general, you should add only just enough frother to get the sort of bubble you want. Therefore, if the machine isn’t frothing to suit you, try to make it right with the machine controls first (the weir bars, the pulp level, the air controls). Only when you can’t get the right conditions with the machine controls should you begin changing reagents.

One exception to this is a condition when you see quite plainly that you have altogether too much reagent. If the froth is boiling over, for example, and it has an oily look and consists of extremely tiny uniform bubbles, go look at the frother feeder. You are probably using too much. In other words don’t hesitate to cut down on reagents if conditions seem to warrant it; but think twice, or three times, before you add more of anything.

There is also an order of preference, you might say, for the machine controls. In general the pulp level in a roughing machine should be carried as high as you can get it and still leave about 2½ to 3 in, of froth above it. (There’s where your froth-depth indicator comes in handy.) This is done to help recover more of the mineral you want. The high pulp level holds the mineral in the machine longer, and gives the air bubbles more chances at it. The thin froth, overflowing rapidly, snaps the weakest-floating mineral over into the concentrate launder before it can drain back.

Because this high pulp level in a rougher machine is harder to regulate than the froth depth, it is better to work with the weir bars along the froth lips instead of with the tail gate, or the weirs between cells, if your machine has them. Also, if your machine has an air control (like the Agitair, the Weinig, or the Pan-American) it is better to keep the valve as wide open on the roughers as you can. This is because the more air you add, up to a certain point, the more mineral you’re likely to pick up. In addition, the more air added to mechanical machines, the less power they draw and the less wear there is on the impeller. In short, don’t cut the air unless you have to and then do it for as short a time as possible.

A flotation machine needs deep froth in order to allow time for unwanted mineral to drain from the froth bubbles back into the pulp. Also, a high pulp level isn’t so important in a cleaner cell, because recovery isn’t what you’re after so much as grade of concentrate. Therefore, in a cleaner cell, a froth depth of at least 8 in. is required in most cases, and you have more leeway in adjusting the pulp level. That is why, in operating a cleaner, you can use the tail gate (or the cell weirs) more than on a rougher.

In cleaning, the rate at which the froth comes over is extremely important, and both the air control and tailing weirs should be used to get the fine adjustment that will give you the best results. Froth scraper adjustment and weir bars, it there are any, may help, but to a lesser extent. Here is where your vanning plaque comes in handy. To run a cleaner properly, you must know what is in the cleaner froth, and the only way you can really find that out is by spreading some of that froth out, not on the palm of your hand, but on a vanning plaque.

All this, remember, is a general statement applied to all operations. In your own mill there may be good reasons why you have to run the machines differently. In that case, find out what pulp level and what froth depth your metallurgist thinks are right, and then keep them that way. But the order of preference still holds, no matter what. On the roughers: weir bars first, then air, then tail gate (or cell weirs), then reagents. On the cleaners: air first, then tail gate (or cell weirs), then weir bars, then reagents. If none of these things works, see if you can’t get a job down in the mine.

Types of Flotation Machine

PNEUMATIC. Nearly everything we have said up to here applies to both air and to mechanical machines. There isn’t much to add that applies only to these machines. In fact, in most cases, air machines are rather easier to control than mechanical machines, though the possible adjustment isn’t so fine, for example on cleaning operations.

HOG TROUGHS. This term rather loosely describes mechanical machines built on the lines of a long trough in which the impellers are set at regular intervals. There are no pipes or weirs between cells. The type is represented by the Agitair, the “Level-Type” Fagergren, and the Pan-American machines, the one tail gate controls the pulp level throughout each group of cells. If you want to vary the pulp level between cells somewhere up the line, the only way is to widen or narrow the opening in the partitions between impellers. There is very seldom any real need for this adjustment, and it is better not to try it.

Having the pulp level in the whole machine controllable by the one tail gate may tempt you to whirl the gate up or down every time an adjustment is indicated. Don’t do it. Pick a level for the roughers that is about right (good and high, remember), and leave it there. If you have to change the gate, return to the original setting as soon as you can. You can spot this by counting the number of threads exposed above the handwheel when the gate is where you think it ought to be. This gives you the exact location of the gate and saves measuring each time.

Poke a stick into the tail box once in a while to see that it isn’t sanding up. If the tail box does get partly sanded up, the pulp level will run higher than you want it and may overflow the machine. Remedy this by opening the sand bleeder gate a little, but don’t open it farther than necessary. Make all the tailing come out over the tail gate if you can.

UNIT CELL CONSTRUCTION. This type of cell is represented by the Weinig, and the older model Fagergren machines. We mentioned “weirs between cells” a lot in our discussion. This is where they are used.

The peculiar virtue of a weir to control the pulp level in each cell is that it permits you to get an extremely nice adjustment of the rate of froth overflow down the length of the machine. One cell fast, the next slow, the next fast, and so on, if you happen to want it that way. This is an extreme example, of course, but it shows what could be done. The practical effect of this flexibility is that you can get an extremely high-grade concentrate with these cells if you handle them right.

But by the same token these individual cell weirs can get you into an awful lot of trouble you don’t handle them right, Here again, we say don’t over-control, and do try to anticipate trouble. If you do get caught, however, and you find the froth has dropped in all the cells, or that the machines are wildly overflowing, start with the tail-end weir, adjust it properly, and so work back up the line of cells to the head end. But take our word for it, it is better not to find the cells in that condition.

You will of course get into trouble now and again. Pipes will plug up, froth will spill out over the floor, belts will break, bearings get hot, launders leak. We just haven’t space to list here all the things that could happen to you and suggest remedies for them. Besides, we don’t know all the things that could happen to you. The important thing, anyway, is to keep your head, figure out the cause of whatever went wrong, and then think up a way to correct it.

One jam an operator always seems to get into sooner or later, however, is this matter of oil or grease in the pulp. A case is on record where a man cleaned the black grease from under the big gear on a ball mill and tossed the goo into the flotation feed launder to get rid of it. The result was a cross between a bubble bath and the Johnstown flood. Oil and grease are frothers, too, but don’t use them as such. If, somehow, oil does get into the circuit and the froth comes pouring out on the floor, all you can do is flush things out as quick as you can, tell the shift boss some miner must have dumped his oil bottle into the muck, and pray he’ll believe you.

This whole discussion could be summed up pretty well in the following suggestions:

- Ask a lot of questions and find cut, from people who know, exactly what it is you are trying to do.

- You control the machines, don’t let them control you.

- Don’t over-control.

- Think about your job and try always to learn more about it. Things like the use of vanning plaques and the proper handling of weirs and air valves are mechanical details that can be learned by practicing with them.

The desire to do a better job is the important thing. Once you have that, the rest will be easy.