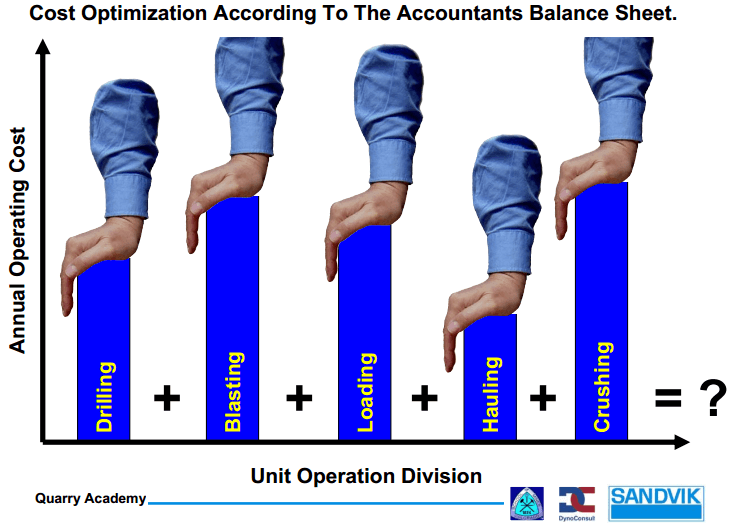

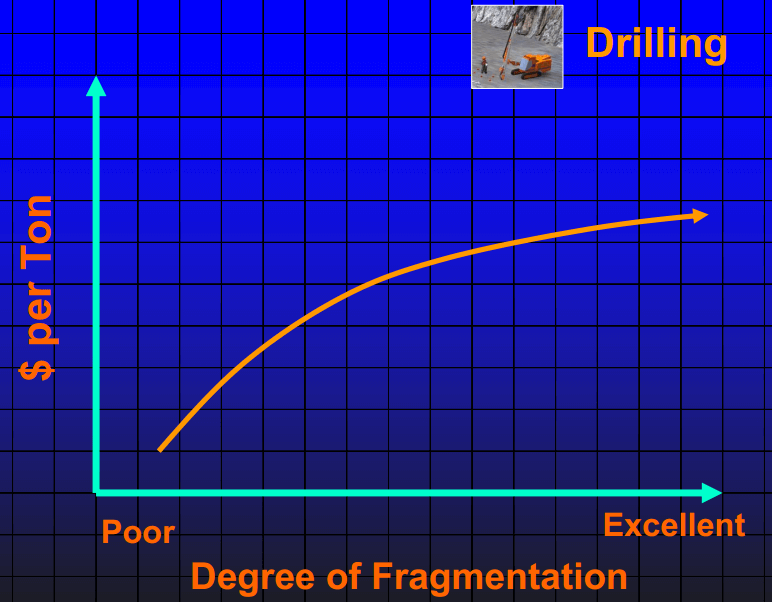

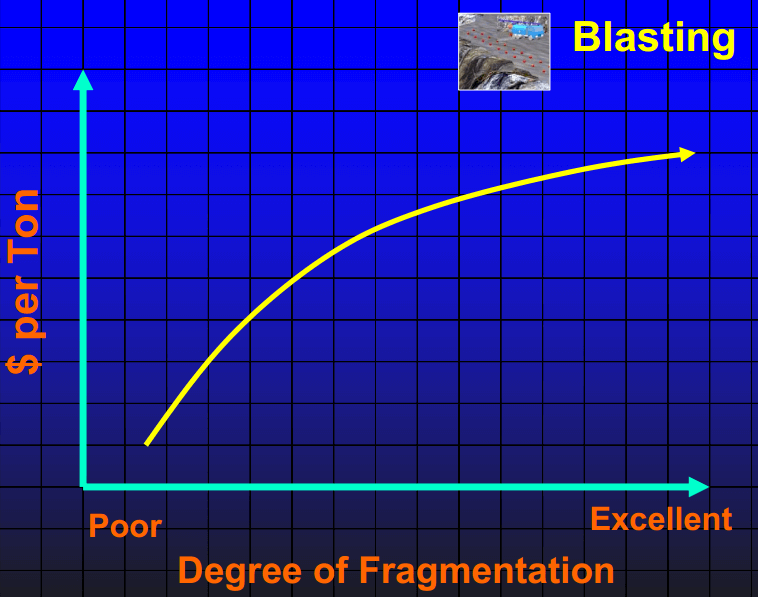

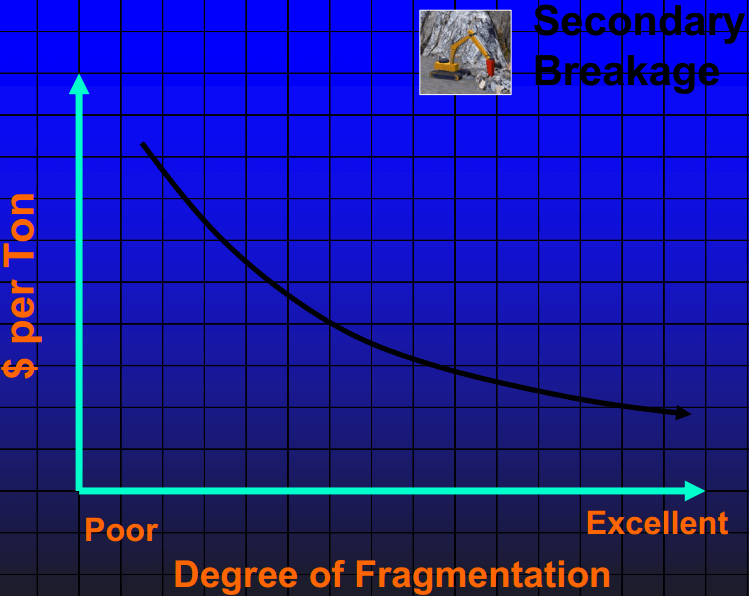

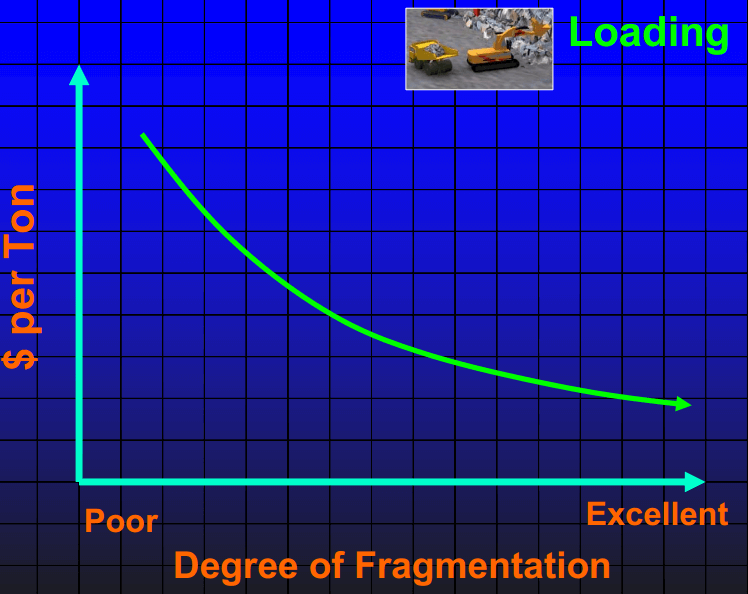

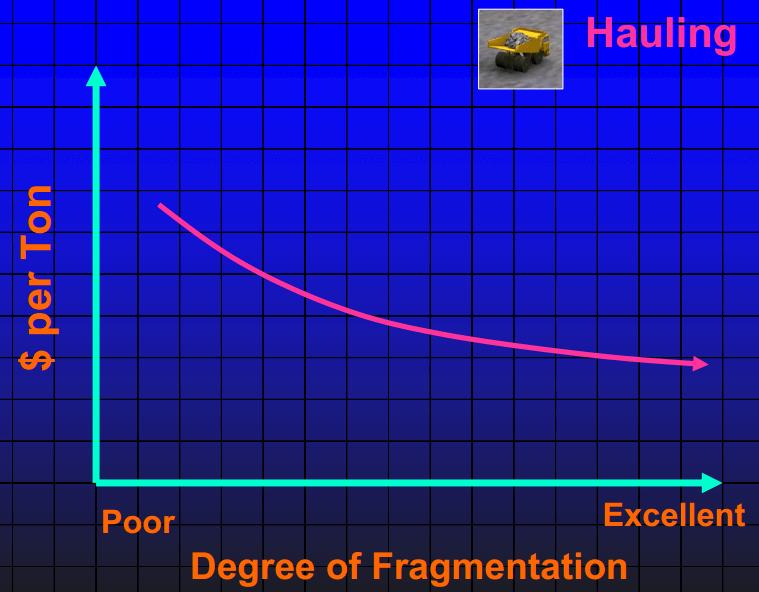

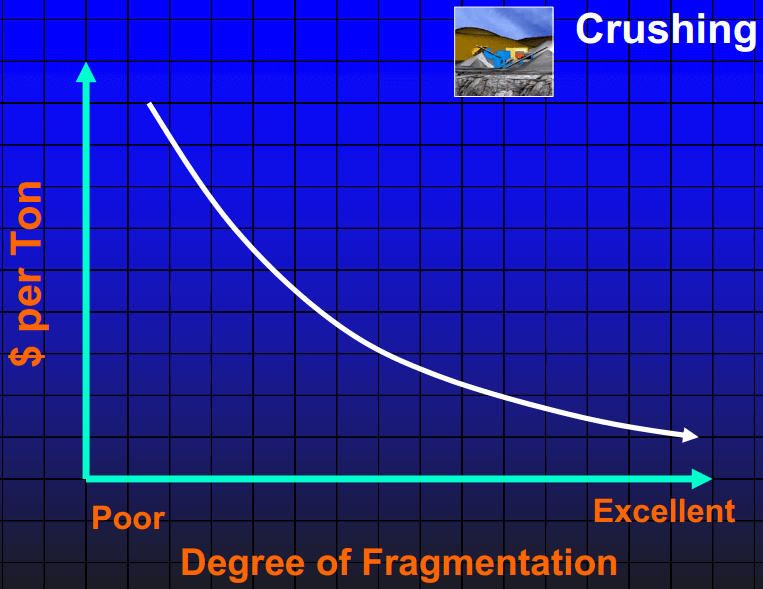

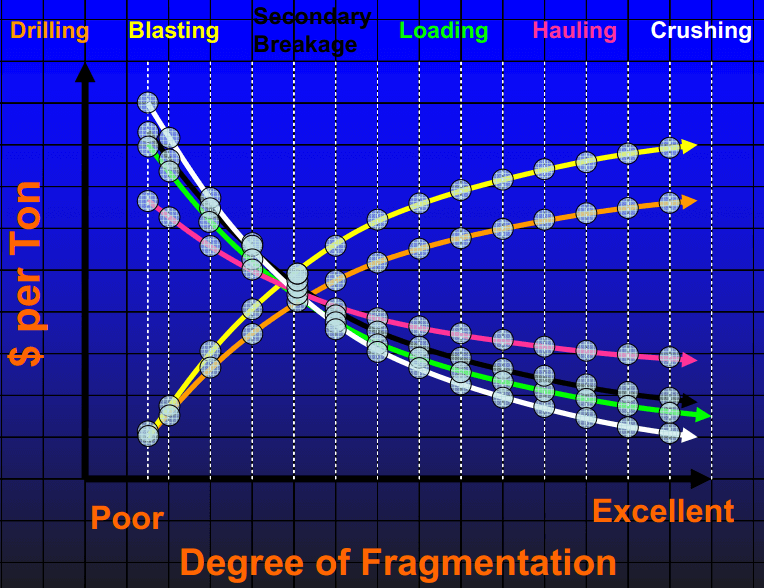

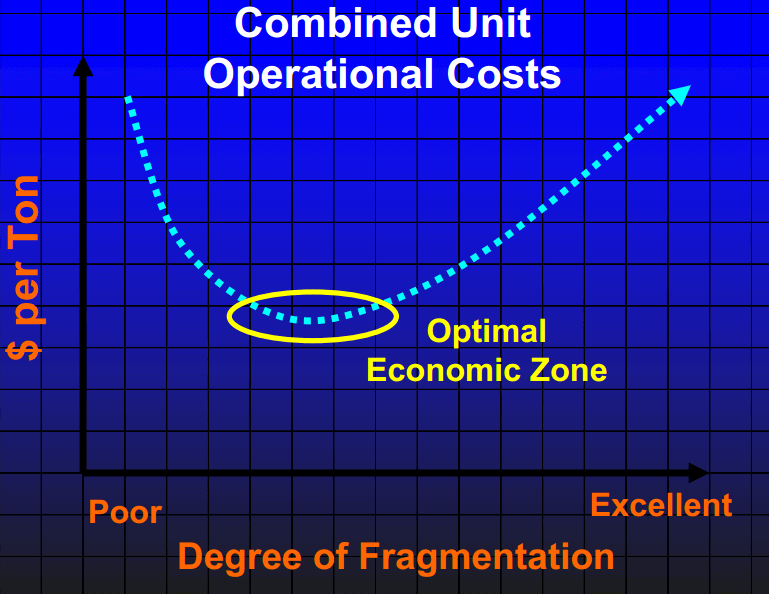

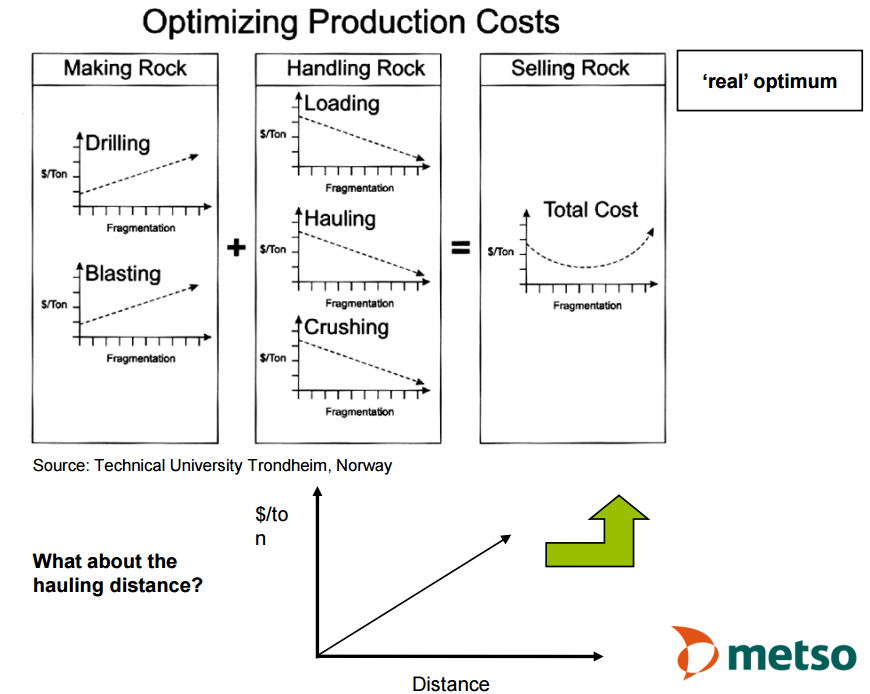

Spending a little extra on drilling and blasting to increase fragmentation will same you multiples ore loading and hauling, then finally crushing.

The Experts: SandVik Mining + Metso and Quarry Academy = all agree.

The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis of an eight-hour crushing day are easy to calculate. The figures must be regarded only as a rough guide to the average costs of modern installations ; they are direct costs and include no overhead charges.

It is assumed that power is charged to the plant at the rate of 0.75d. per kilowatt-hour in the case of the smallest plant, decreasing as the capacity increases to a minimum of 0.5d. per kw.-hr. for the largest. The power consumption of a machine or installation is usually expressed in kw.-hours per ton as being the most convenient method.

In every case the power consumption is in excess of the figure that would be obtained by totalling the power requirement of each individual machine when running at full load for the whole eight hours, the reason being that a crushing plant can very seldom be kept working at full capacity all the time ; if it could, the power consumed would be at least 25% under the figures given. It is time lost when the machines are running at less than full load that brings up the power costs.

The power cost falls as the size of the plant increases up to a capacity of about 2,000 tons per day on account of the fact that large machines are more economical as regards power up to a capacity of about 250 tons per hour ; single machines are made to handle greater tonnages than this, but their power consumption per ton crushed shows no appreciable saving.

The labour cost is the largest item in small and medium plants. This is one reason for the modern tendency towards a larger ratio of reduction in the minimum number of crushing stages, since the simplification of the layout that results reduces the cost of operating and maintenance labour considerably, besides that of power and supplies. As was explained in the previous paragraph, the mine output, if it does not exceed 2,000 tons per day, is usually crushed in one shift in order to reduce the cost of labour, since two shifts require double the number of men for the same output.

The wear on the liners of the crushing machines accounts for less than half of the cost of supplies. With manganese steel liners the steel consumption can be relied upon never to exceed 0.1 lb. per ton crushed for any of the machines described in this chapter, and as a rule it is considerably less. General wear and tear of the accessory plant and accidental breakage due to the very rough nature of the work that the machines have to perform is responsible for most of the cost of supplies ; lubrication and routine replacement of worn parts other than liners are not costly items.

It will be seen that there is a gradual fall in the total direct cost as the size of the installation increases up to a capacity of about 500 tons per hour. Above that figure the decrease is so small as to be negligible for purposes of rough calculation ; in any event, small economies only can be expected, chiefly in the reduction of the cost of supervision and of general overhead charges.