Let’s review the steps to collect a sample of coarse rocks such as primary Crusher product. The procedure requires that Process Equipment be shut down and so it is important to organize the work to minimize lost time.

Let’s review the steps to collect a sample of coarse rocks such as primary Crusher product. The procedure requires that Process Equipment be shut down and so it is important to organize the work to minimize lost time.

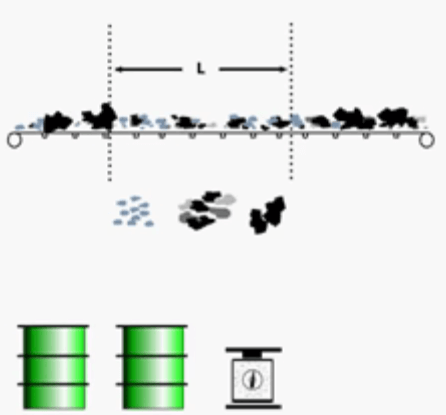

First the particular conveyor where the sample is to be collected is identified, next, one to two drums are placed near the conveyor since a sample weighing between 500 and 800 kilograms will be collected, a weight scale is also setup near the sampling point. With everything in readiness the procedure begins. the belt speed is checked this is done by marking two points along the conveyor way, the distance (D) between them is measured, The time (T) for the belt to travel between them is also measured, the belt speed is equal to the measure distance divided by the measured time, this information will be needed later during the analysis of the sample.

Next the conveyor is crash stopped, this is done to retain all rock on it unless the belt is drawing or from a stockpile any upstream equipment that is feeding the belt must also be stopped at this point all persons designated to on the belt must lock out the equipment with the conveyor stopped and locked out, a sampler walks along the belt removing all rocks larger than 75 millimeters until at least 50 such rock have been gathered.

The point where he started collecting is noted, the distance (L) required to collect at least 50 larger rocks is measured. This measurement is needed to calculate the weight proportion of oversized rocks in the interval sample that will be taken the next step.

After the large rocks are collected, a sampling interval of to 25 meters are marked out. All material on the conveyor within the sampling interval is carefully removed and transferred to the drums. Care must be taken to collect all material in the interval and nothing outside of it. On finishing the interval sampling the crew clears off the belt and everyone removes their locks from the conveyor starter so that it can be quickly restarted.

Now the oversized rocks collected earlier are weighed, the oversized is returned to the conveyor belt, the drums of finer particles are removed to the lab where they’re screened to produce a cumulative size distribution.