Hydraulic classifiers range from simple V-shaped launders with a multiplicity of shallow settling pockets for the discharge of as many roughly sized products to the more elaborate deep-pocket machines of the hindered- settling type, having specially designed construction plates and automatic discharge of spigot products.

Dorrco Sizer

In the eight-pocket machine, the pockets are separated by 3-ft.-high partitions and increase in cross-sectional area from 1 sq. ft. in the feed end to 3.12 sq. ft. in pocket 8. The size of hole and hole spacing in the constriction plates depend upon the size distribution of the feed and are designed individually for each installation, so that the hydraulic water required for each compartment will flow through the holes at a predetermined head loss. This hydraulic water is supplied from take-offs arranged along a common manifold, and the flow is controlled by individual valves. Windows are provided in each compartment for inspection of the teeter bed. The discharge mechanism is fully automatic, the spigot valves being operated by a modulating motor controlled by a pressure unit that, in turn, is actuated by the pulp density within the compartment. This eight-pocket unit operating on minus 14-mesh iron ore of average size distribution has a feed capacity, when overflowing minus 100-mesh material, of about 25 tons of solids per hour.

Hindered settling machines require no power except for the water used and are automatic in discharge, although they need a certain amount of attention. On many materials they give excellent results either in closeness of sizing or in concentration of the denser particles. They are used, therefore, chiefly for two purposes—either in separating 6- to 200- mesh material into a series of closely graded portions for subsequent treatment or in concentrating the heavier mineral of a non-homogeneous feed.

In general, however, hydraulic classifiers use more water than mechanical classifiers, the slime overflow is more dilute, the coarse fractions contain a much higher moisture content, and the loss of head on the sands is considerable, which is objectionable in closed-circuit grinding. Also, these classifiers frequently require a deslimed feed.

Thus in practice, for preparing cyanide or flotation pulps, mechanical, non-hydraulic classifiers are used almost to the exclusion of all other types because of their capacity, flexibility, continuous operation, and uniformity of results. In addition, they require little attention and give a coarse portion or sand of low moisture content. Furthermore, the mechanical- type classifiers give a coarse portion that is sufficiently free of fines for practical closed-circuit grinding. This is the result of the agitation and draining that take place during the removal of the coarse portion.

HYDROSEPARATORS

A hydro-separator is, in working principle, an undersize thickener, i.e., a machine of such a specified diameter that the upward displacement rate is greater than the settling velocity of the largest particle it is desired to separate. In consequence, particles of this critical size and finer are carried into the overflow, and the settled material, which is carried to a central discharge opening by a slowly moving raking mechanism, is relatively dislimed.

As in the case of mechanical, in contrast to hydraulic, classifiers generally, a considerable amount of the finer fraction is entrained with the underflow sands. Used both as “deslimers” for making final separations after grinding and also for closed-circuit grinding work, they have the advantage of providing the relatively large areas required for fine separations at high dilutions.

Where it is necessary to handle heavy sands in the machine, steep sides and extra-heavy raking mechanism are provided.

The capacity of hydro-separators can be determined from the following formula:

A = 1.333(F + 1/sp. gr.)/R

where A = square feet per ton of overflow per 24 hr.

F = overflow dilution

R = settling rate in feet per hour at over-flow dilution F

sp. gr. = specific gravity of the solids

Having determined the ratio of feed to overflow, the unit area per ton of feed is readily calculated.

The metallurgical advantage of fine grinding in the treatment of many ores by the all-sliming cyaniding process has of course been realised ever since the introduction of the process. An economical means, however, of attaining a finely ground product has been a gradual development to which improvements in grinding mills and classifiers have contributed the greatest advance.

The mill-classifier combination should be considered as a unit. The change from open circuit to closed circuit, the use of optimum circulating loads, and the development of secondary and tertiary grinding circuits are notable advances in producing an improved product, generally resulting in a higher extraction of the valuable constituents of the ore. This has been accompanied by a reduction in unit costs through a lowered consumption of power and steel and by increase in capacity of the grinding mill.

What are Hydraulic Classifiers

Classification as applied to cyanide plants is usually a combination mechanical-hydraulic operation which separates the solid constituents of a flowing pulp into two portions according to their respective settling rates. Usually it implies the removal of a finished product, termed “overflow,” from a product requiring further grinding, termed “sand.” Pulp means a uniform suspension of finely divided solids in liquids as applied to mechanical classification, which is the usual method of making a sand-slime separation in cyanide plants. Overflow is the comparatively finer, more slowly setting portion of the original pulp which is carried over the tailboard or lip of the classifier by the flow of water; sand is the comparatively coarser, more-rapidly settling portion of the original pulp which is discharged from the classifier by the mechanical action of the rakes. Selective classification is classification that has for its object the concentration of the heavy constituent of the original pulp, generally the sulphide, in the sand product, so that it may be ground finer than the lighter portion, generally the gangue.

A grinding mill may operate open circuit or closed circuit. Open-circuit grinding is a method of comminution that produces the desired reduction in particle size by a single passage of the material through a mill. Closed- circuit grinding is a method of comminution in which a partly finished mill discharge is separated by the classifier into a finished overflow product and an unfinished sand product which is returned to the mill for further grinding.

When to your a Hydraulic Classifier for CLASSIFICATION

- To make a size separation, for example, a sand-slime separation so that each product may be given a different treatment.

- For closed-circuit grinding, so that the maximum size of particle escaping from the circuit may be limited and so that the useful work done by the mill may be increased by enabling the mill to operate largely in reducing oversize rather than in overgrinding material already fine enough.

- For differential grinding of the heavy mineral constituent and the gangue, by selective classification which, concentrates the mineral in the sand product and causes it to be ground finer than the gangue before it can escape in the overflow product.

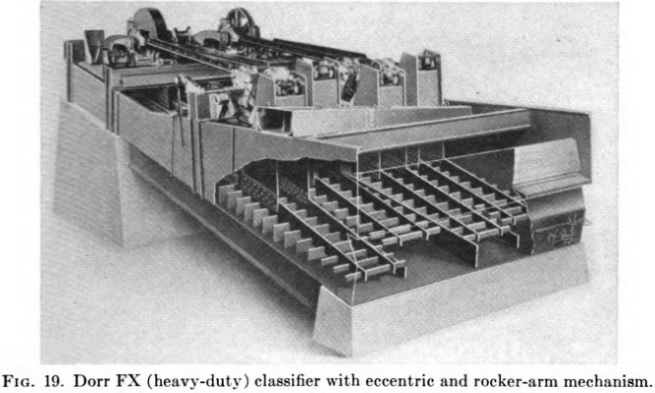

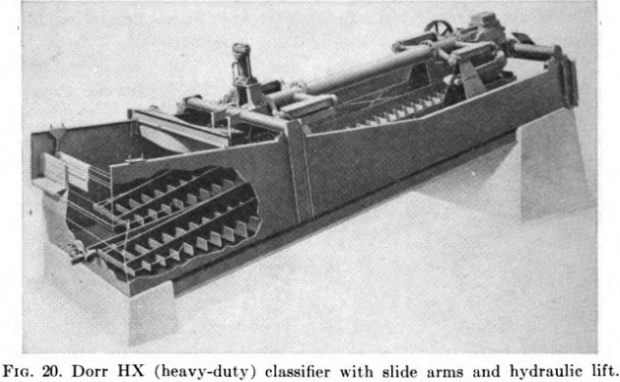

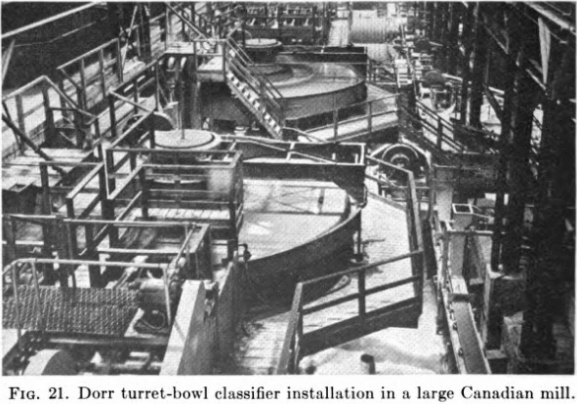

The desired function, together with the character of the ore and such factors as the tonnage to be handled, mesh of separation, etc., determines the selection of the proper size and type of classifier. The single-stage classifier such as the Dorr (see Fig. 19 and 20), Akins, and Wemco, and bowl-type classifiers such as the Dorr (see Fig. 21) are in use for making separations from as coarse as 20 to as fine as 350 mesh. The first of these are better suited for making coarse separations and for handling large circulating loads where relatively small overflow capacity is required. The bowl classifier, limited to 48 mesh and finer, with the double washing action gives a closer separation at the desired mesh and a cleaner sand product; permits, through the selection of the proper bowl size, any required relation between overflow and sand-raking capacity; and is more suitable as a mineral concentrator for selective classification.

Both machines are capable of adjustment to cover considerable range of conditions. Adjustments in slope of classifier tank, rake speed, and dilution of overflow pulp and, in the case of the bowl classifier, additional adjustments of backwash water and bowl speed are available to obtain efficient results at any mesh of separation. In designing the machine, due consideration is given the results desired under specified conditions; final adjustments are made when the particular flow sheet is placed in operation and are varied thereafter as the conditions vary.

The evolution of fine-grinding flow sheets can be described as follows:

Open-circuit Grinding

The first application of the mechanical classifier was to open-circuit work with grinding mills in the cyanidation of gold and silver ores, for the purpose of producing two products—a slime-free sand for treatment by percolation and a sand-free slime for treatment by agitation and filtration or decantation.

Closed-circuit Secondary Mills

Advances in the art of treating cyanide slimes and the reduced cost of fine grinding made possible by the early tube mills led to the use of the mechanical classifier as a means of controlling the fineness of the pulp leaving the grinding plant as feed to the all-slime cyanide treatment. Operating in closed circuit with the tube mills, the classifier not only controlled fineness more accurately but greatly reduced grinding costs.

Closed-circuit Primary Mills

The adoption of two-stage fine grinding, due to a recognition that too great a size reduction in one mill with one ball charge was uneconomical, led to the use of the primary mill and subsequently a mechanical classifier in closed circuit with it. Reductions in grinding costs were again obtained, and in addition a convenient means was provided for apportioning the work between the two stages.

Intermediate Classification between Stages of Fine Grinding

Another step was the interposition of a bowl classifier between the primary and secondary grinding circuits. The classifier operated in open circuit receiving as its feed the overflow from the primary circuit, overflowing material of finished size, and discharging a clean sand product direct to the closed-circuited secondary mill. This step, however, is not generally desirable largely because of the difficulties met in controlling the succeeding classification stage in the absence of primary slime.

Finishing Bowl Classifiers

Finishing the entire mill feed in a bowl classifier, with provision for regrinding the sands in a separate or tertiary circuit, first proved attractive in the cyanidation of gold ores in which the values were chiefly associated with the heavy pyrite constituent. Here the bowl reclassified selectively the relatively coarse pulp from the secondary circuit, overflowing the bulk of the quartz and only the finest sulphides for treatment, concentrating the sand product to five or six times the assay of the original ore, and regrinding this high-grade material as fine as its assay warranted.

The net result has been a higher extraction, a coarser over-all grind, and a reduced grinding cost.

The same principle has been applied successfully more recently in the dressing of copper sulphide ores for flotation. The sulphide mineral, being heavier than the gangue, concentrates readily in the bowl sand and is subjected to regrinding for more complete liberation of associated minerals. In this way the mill is not burdened with gangue material upon which no further work is required. Moreover, the finishing-bowl classifier protects the flotation operation against tramp oversize from preceding classifiers and assures a uniform product from the entire fine-grinding section, convenient for sampling and distribution to the succeeding units.

MEANS OF CLASSIFICATION

The type of machine best suited to a specific classification problem will depend upon:

- whether a finished product is required,

- the size range of material to be handled, and

- the volume and dilution of the pulp entering the machine.

In general, open-tank rake-type, screw-type, or bowl classifiers are used for closed-circuit grinding work where a finished product is desired. In some cases, however, especially for very fine separations requiring high overflow dilution, hydroseparators are used to good advantage, and because of the difficulty of raking extremely fine sand up an inclined deck, bowl-type classifiers have been converted to shallow hydroseparators with spigot discharges. The open-tank rake-type or screw-type machines are also more generally suited to coarser sizes of feed, while the bowl classifier, hydros, and centrifuges are applied more generally to handling finer (minus 20 mesh) feeds and to making finer separations. Where exceptionally large volumes must be handled, however, the hydroseparator has been installed to handle feeds as coarse as 4 mesh, using a spigot discharge. Hydraulic classifiers operate in the size range of about 8 to 200 mesh but find their principal use in preparing a number of closely sized products and in the concentration of heavy minerals.

CONE Shaped Hydraulic Classifiers

Screw Classifiers

Screw classifiers such as the Akins and Wemco consist of a semi-cylindrical trough, usually set at a slope of from 2½ to 3½- in. per ft., in which rotates a helix or spiral at from 2 to 8 r.p.m. depending upon size and conditions to be met.

The feed is introduced through the side of the tank just below the pulp level. The heavier solids settle out and are carried upward out of the pulp by the spirals and discharged into a sand launder, while the fines flow in the opposite direction to the overflow weir at the lower end of the tank.

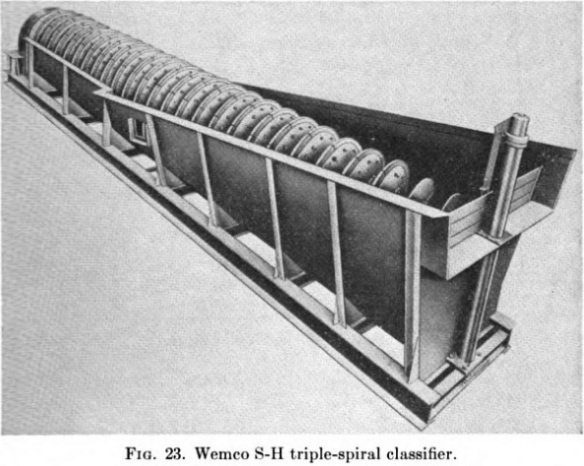

The earlier types of machine used interrupted spirals and overflow lips below the shaft carrying the spirals at the lower end. The design has now been modified. In the “high-weir” type recommended for coarser separations the spirals extend above the pulp level, and in the “submerged” type recommended for fine separations the spirals are below the pulp level in the lower end of the tank. Either type may be supplied with single or double spirals, and both are equipped with lifting devices. Figure 22 shows an Akins submerged-type machine. In the triple-pitch Wemco design (Fig. 23) three spirals per shaft provide additional sand-conveying capacity per revolution.

Reciprocating Rake Classifiers

The Dorr Company is the principle advocate of this machine. Single-stage Type. The Dorr classifier (Figs. 19 and 20) consists of a rectangular, inclined settling box of wood, steel, or concrete, with the upper or discharge end open, in which are placed mechanically operated rakes or scrapers which carry the quick-settling, coarse particles to the point of discharge at the open end. Each rake, of which there may be as many as six, is carried by two hangers, one at the discharge end and one near the overflow end. The rakes are raised, lowered, and moved parallel to the sloping tank bottom by a suitable head motion. A lifting device is provided for raising the rakes several inches to clear the settling solids in case of a shutdown.

The feed enters continuously, through a distributing launder near the overflow end. The more quickly settling particles fall to the bottom and are advanced up the inclined deck by the rakes and discharged. The agitation of the reciprocating rakes keeps fine particles in suspension until they overflow the weir at the lower end.

The point at which a separation can be made is determined by the rake speed, the pool area, and the overflow dilution. The greater the rake speed the greater the overflow density, and the smaller the pool area the coarser the separation.

Bowl Type. The Dorr bowl classifier (Fig. 21) is a combination of a shallow, circular bowl with a revolving raking mechanism superimposed on the lower or overflow end of a single-stage Dorr classifier. Feed enters through a loading well at the center of the bowl, and fine solids overflow across a peripheral weir. Coarse solids settle on the bowl bottom, are raked to a central opening, and gravitate through it into the reciprocating- rake compartment.

It is used where a clean rake product is desired, where a separation at a fine mesh is to be made, or where the overflow capacity must be large in comparison with raking capacity.

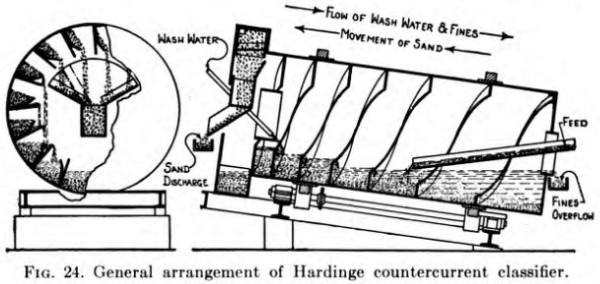

Hardinge Classifier

The Hardinge Company was responsible for introducing the spiral ribbon type of mechanical classifier as illustrated in Fig. 24. This classifier is a slowly rotating drum, on the inner surface of which is a screw flight attached to the drum, revolving with it. The material to be classified is fed in at one end above the pulp level, and as the classifier rotates, the coarse particles that settle out are moved forward by the screw flight. The fines overflow through an opening at the feed end of the classifier. The sand or oversize is dewatered and elevated by buckets to the discharge hopper.

DESLIMING

Desliming for Separate Treatment of Primary Slime

A number of mill flow sheets include the step of removing the softer fraction of the ore (clay and related material) from the harder fraction preceding or as a part of the crushing and grinding sections.

At Marlu Gold Mining Areas in West Africa (Fig. 89) the ore after passing through a jaw crusher is washed at 1½-in. size in a series of twelve 4 by 16-ft. trommel washers, the undersize being sent to bowl classifiers for desliming and the washed rock being crushed in Newhouse crushers and passed to the ball-mill circuit (which also receives the sands from the desliming classifiers).

At the Dome mines in Canada (Fig. 64) the jaw-crusher product is first washed on vibrating screens, the oversize passing to a-Symons cone crusher, while the undersize is. classified for removal of fine sand and slimes and the rake sands transferred to the mill bins.

In both of the above installations the objective is, of course, to eliminate primary slime which in the case of wet ores causes trouble in the crushers, but the combined pulp is cyanided in a single circuit.

In the case, however, of the treatment scheme devised to handle a difficult ore in the plant of the Kelowna Exploration Co. at Hedley, British Columbia (Fig. 71), the primary slime and softer fractions of the ore are treated in a separate circuit from that used to handle the harder ore constituents. This scheme has resulted in the successful treatment of an ore that otherwise failed to respond to ordinary thickening and filtering practice.

CENTRIFUGAL CLASSIFICATION

Bird Centrifuge

This machine is essentially a closed spiral classifier in which the tank is revolved at relatively high speed on a horizontal axis. The tank itself consists of a truncated conical shell, within which is a smaller concentric cone carrying a spiral ribbon (rakes) that revolves independently of the shell but in the same direction at a somewhat slower speed. Classification takes place in the annular space between the cone and the shell, the speed differential between the two elements having the effect of raking the solids settled against the shell up-slope to the small end, where they are discharged. The slime discharges through ports at the larger end. The machines are built in various sizes ranging from a raking capacity of 2 to 50 tons per hour, the latter requiring a 100-hp. drive motor.

At the Hedley Mascot mill in British Columbia, a change in the ore mined led to a serious slime problem which could not be handled in the conventional flotation and cyanide equipment installed at the mine. Following test work, a 36- by 50-in. Bird centrifuge was installed in January, 1941, to deslime the ore prior to flotation and has been in continous operation since.

According to C. W. S. Tremaine in “Applications of the Bird Centrifuge at Hedley Mascot Mill,” C.I.M. andM., Vol. 50, pp. 533-536, 1947, the centrifuge is operating on a mixture of slime from primary and secondary classifiers and concentrate taken from the scavenger flotation cells.

This mixture of slime and low-grade concentrate forms the feed to the Bird centrifuge; it amounts to about 2.5 tons per hour at 15 per cent solids, 98 per cent minus 325 mesh, and assays about 0.11 oz. per ton. The centrifuge discharges an effluent which carries 3 to 6 per cent solids and assays 0.06 oz. gold per ton. The cake is discharged at about 82 per cent solids, 92 per cent minus 325 mesh, and is sent to the cyanide plant, where it is treated in conventional manner. The centrifuge machine is driven by a 30-hp. motor and operates at 1000 r.p.m.

DSM Cyclone

The hydraulic cyclone, which was developed by the Dutch States mines in connection with their coal-cleaning processes, is the most recent classifying-thickening device to be used commercially for the separation of fine particle sizes.

The design and principle of operation of the hydrocyclone are similar to that of the familiar dry cyclone or dust collector. It is a closed vessel consisting of a conical section surmounted by a cylindrical section of equal diameter. The feed is pumped into the cylindrical section at a pressure of 5 to 50 lb. per sq. in. through a tangential opening, the fines overflowing through a central orifice on top and the coarser fraction discharging through a second orifice at the apex of the cone.

The high rotational velocities developed inside the vessel set up centrifugal forces equal to many times the force of gravity, and high rates of separation are obtained. The coarser material is thrown to the sides of the cone and forced by a pressure differential toward the discharge orifice, emerging as a thickened sludge, while the fines are displaced through the overflow opening.

The capacity of the hydrocyclone and the separations made depend upon a number of design factors, including the shape and size of the vessel, the pressures used, and the size of overflow and discharge orifices.

Though still in the experimental stage, performance data to date indicate that this device will find considerable use in the field of classification and desliming. It possesses the advantage of high capacity for size and relative simplicity of construction, which involves no moving parts. The only power required is that used for pumping the feed into the vessel.

Cyanidation and concentration of gold and silver ores