The Mineral Jig is not just another gravity Separation Process. It is a highly efficient selective pulsator and concentrating machine which has the ability to treat an unclassified feed separating solids having only a slight differential in settling rates, with only a minimum addition of water.

1000s of these Mineral Jigging machines are now in operation on a “24-hour per day” basis and they are successfully used on practically every type of ore ranging from massive sulphide to others low in mineral ratio, and some which are completely oxidized. Both metallic and non-metallic ores are being handled, with equal efficiency.

The principle behind the success of the Mineral Jig focuses around its adaptability to a wide range of problems under varying operating conditions large capacity, minimum water requirements, extreme selectivity, foolproof jigging operation.

Working Principle for Effective Jigging

The Mineral Jig operates on the basic principle of hindered settling, and in order to effect a concentration it is necessary that there be a differential in the settling rate of the solids treated. As there is an accumulated differential in settling rates in the grinding mill discharge of a conventional closed grinding circuit, this is an ideal feed for the MINERAL JIG. In addition, this is an enriched product due to the settling and trapping of the higher specific gravity mineral particles in the classifier pool, and concentrate removal from the closed circuit is imperative.

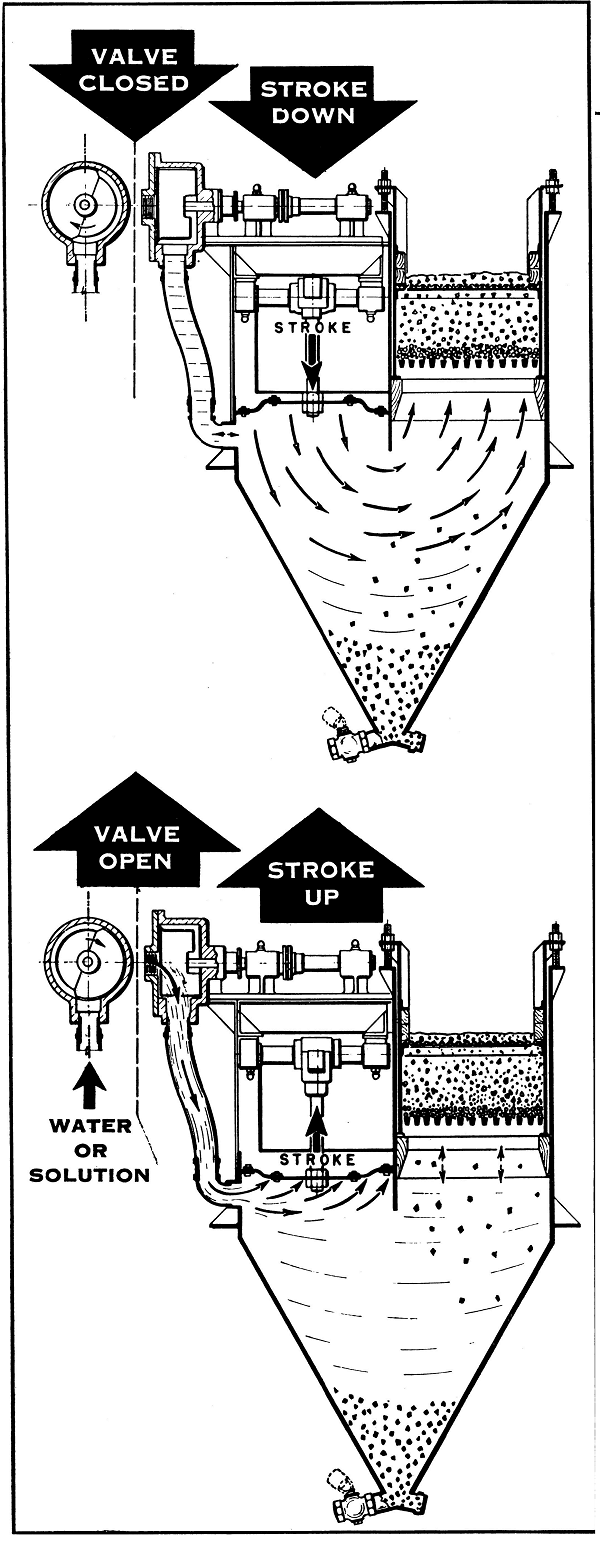

The illustration at the left clearly shows why the MINERAL JIG is distinctive and differs radically from a conventional type jig and why it has been called a pulsating selector.

In the upper sectional view the rotating water valve (synchronized with the eccentric shaft) has closed and the plunger is moving the diaphragm on its downward stroke which creates an upward pulsation to the JIG bed. During this period lighter gangue particles are carried further than the heavier mineral particles which may even settle against the upward movement in the pulp. At the completion of the upward pulsation the rotating water valve has passed through a 180° arc or half of a circle.

Types of Jigging Machines

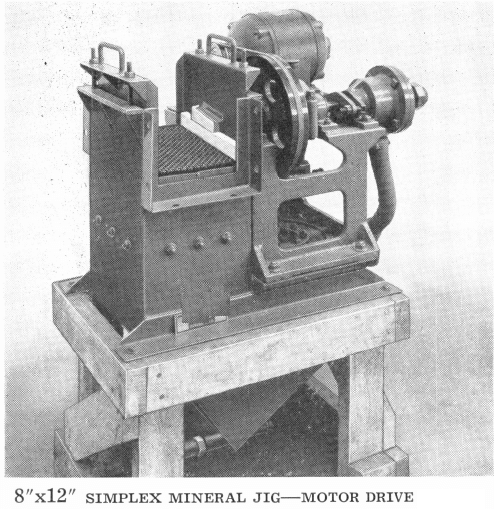

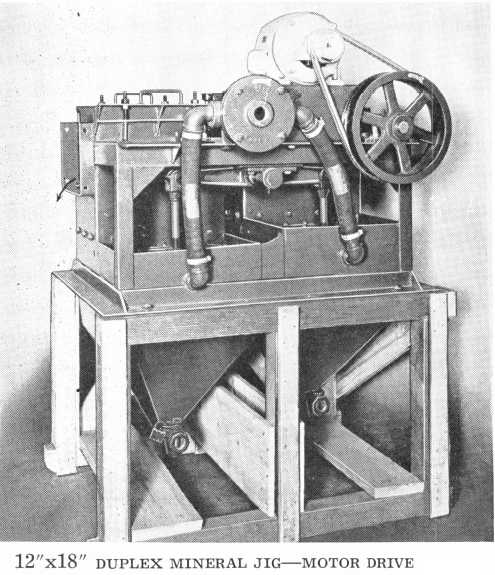

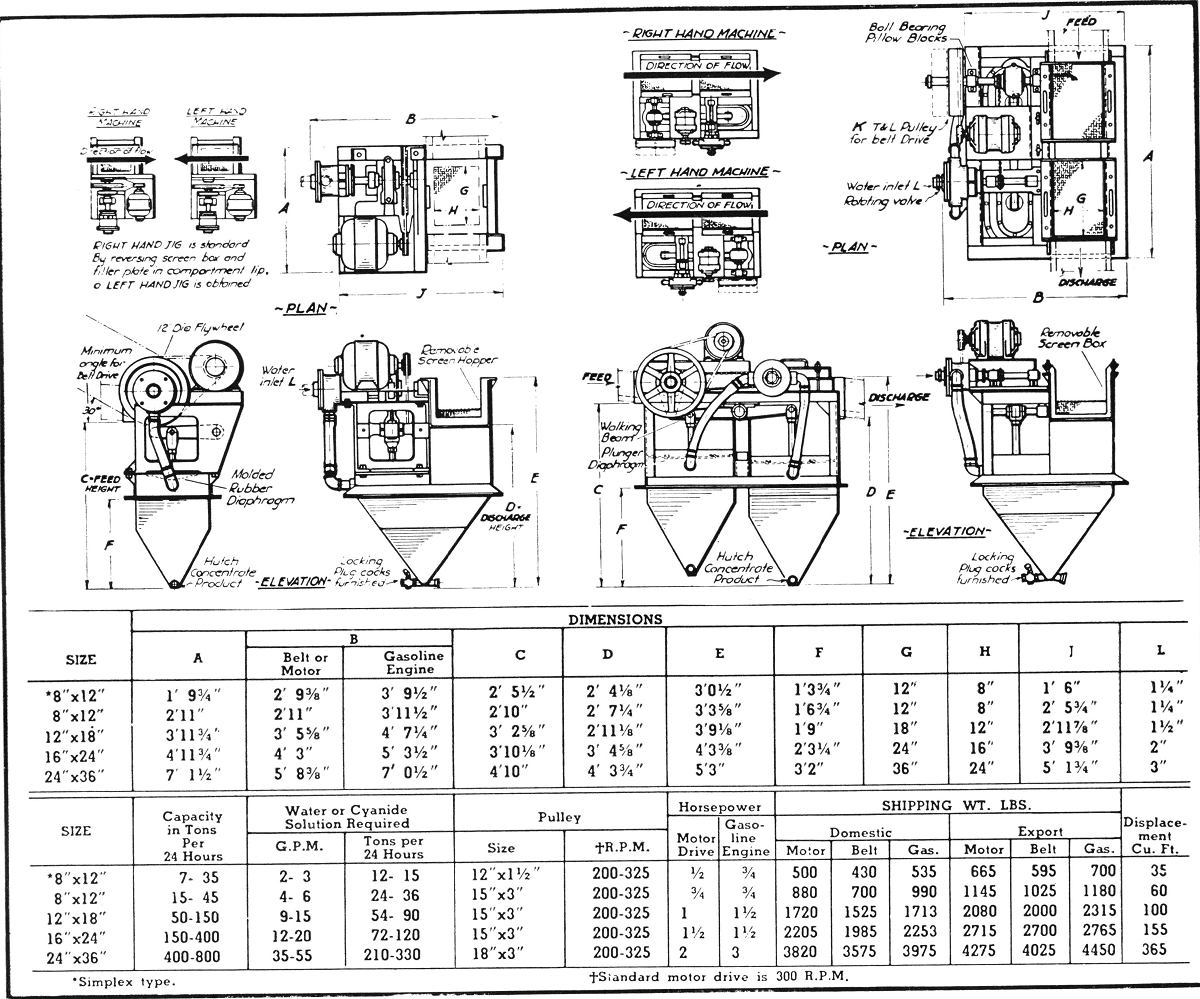

The Mineral Jig is built in two general types, simplex and duplex. The duplex type is built in all sizes while the simplex is standard in the 8″x 12″ size only.

The simplex unit consists of one screen compartment, one hutch, and one screen box, while the duplex is just double, i. e., two screen compartments, two hutches, and two screen boxes.

Each machine is furnished standard with sufficient shot for initial bedding, locking hutch cocks for each hutch, necessary screens and equipped for operation. To facilitate changing screen boxes it is recommended that a spare screen box with screens be available, although this is not necessary.

Jig Drives

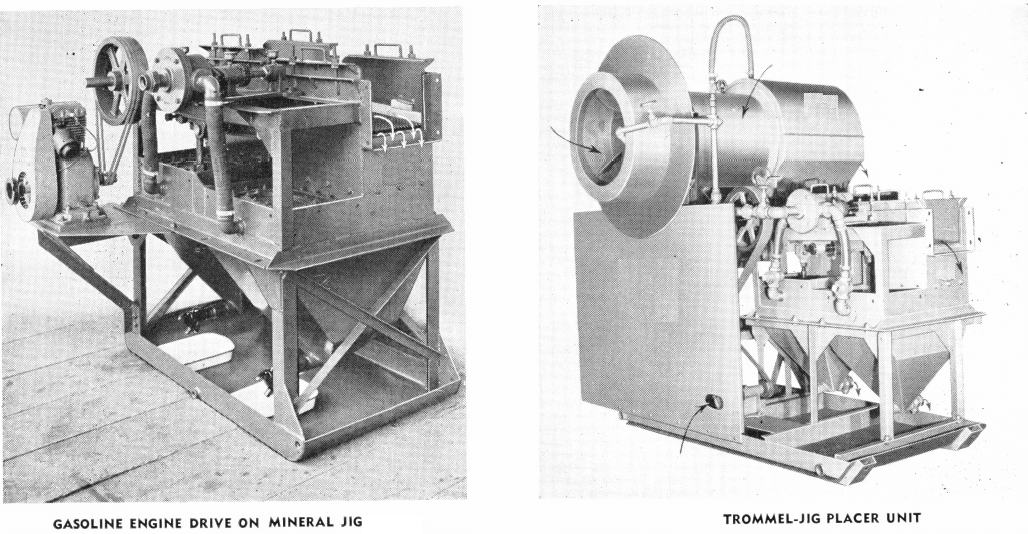

ALL JIGS are available in any of three types of drives, i. e., belt, motor and gasoline.

MOTOR DRIVE: Motor driven units may be of any standard electrical characteristics, either A.C. or D.C. Splash proof motors are recommended and furnished as standard. The drive is through V-belt to the grooved Jig flywheel. Electrical characteristics of the Jig power supply should always be given.

BELT DRIVE: All units may be belt driven from lineshaft to Jig flywheel. Except in the case of the simplex unit, a loose pulley can be furnished if desired. The Jig flywheel acts as the tight pulley.

GASOLINE DRIVE: Gasoline Engines are used to power all sizes of Jigs through V- belt to grooved flywheel. For isolated localities this makes an ideal unit. All Mineral Jigs are readily adaptable to airplane transportation due to compact nature of the various units.

Hand of the Jig

The Hand Of The Simplex Jig is interchangeable, left or right, and may be adapted to any grinding circuit.

The hand of duplex Jigs is determined by facing the rotating water valve, and with feed entering from the left and passing to the right, the Jig is right hand. A Jig is a left hand unit when facing the rotating water valve—mechanism side; the feed passes from right to left. Note the layout drawings showing the hand of Mineral Jigs. In any conventional grinding mill-classifier circuit the Mineral Jig can be installed in place of the regular launder as the flow slope over the Jig is the same as with the launder.

Jig Sizes and Jigging Capacity

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.