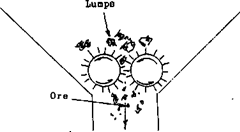

In cold climates, winter is an enemy of all three kinds, this is due to the ore freezing and becoming a solid mass of LUMPS. When this happens simply getting the ore out of the bin may become the hardest part of the operators day. These lumps will not go through the feeders. PRY BARS, AIR LANCES sometimes even EXPLOSIVES will be used to try and make them small enough to fit through. If they can be made small enough to reach the feeders, some mines have MECHANICAL LUMP BREAKERS installed in the area directly above the feeders. These are simply metal fingers or rollers that are revolved catching and breaking the frozen mass.

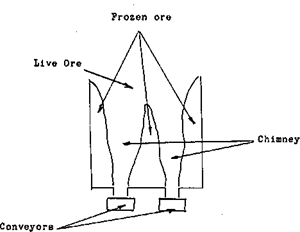

When the ore freezes in this manner there is another condition that the operator must be aware of.

As the ore freezes it, of course, quits moving. The area that is still being pulled to the feeders is referred to as LIVE ORE, the frozen portion as DEAD ORE. The live ore will be in the shape of CHIMNEYS that may run all the way to the top of the bin. The extent that the bin is frozen will determine the amount of live ore that is available for processing. To prevent unnecessary down time due to a lack of available ore the operators must continually monitor the condition of the bins to determine how much RUNNING- TIME is available.

This group of feeders do not have any constantly moving parts and their surface area that which is exposed to the abrasion of the ore flow is very minimal. This makes wear a minor problem. A much larger problem and one that is very costly to the operation is foreign material in the ore. Metal plates and bars from the crusher plant that has been sharpened by the ore passing over them will break off and end up in the fine ore bin. Sometimes a piece of steel will accidently get kicked or dropped into the bin, these objects will be fed into the feeder until they are lodged against the rubber surface of the conveyor belt. One revolution of the belt and it can be ripped in half-length ways. If this happens the belt must be replaced. It cannot be repaired. The operators checking the equipment often and thoroughly will go a long ways towards preventing this from happening.