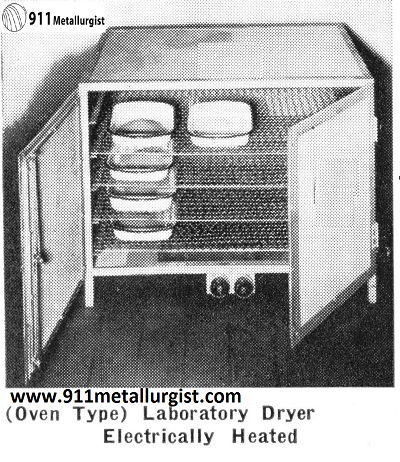

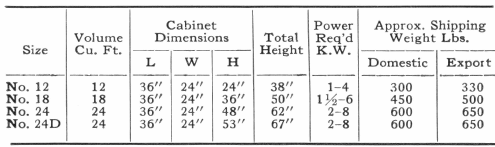

Oven Type Laboratory Dryer

For drying ores, concentrates, grains, or other pulps in the laboratory, the (Oven Type) Laboratory Dryer is a very efficient and inexpensive unit. The cabinet contains five heavy wire mesh shelves which allow the air to circulate freely. A substantial and accurately wound resistance element is located in base and shielded against spillage.

The method of insulation is unique in that the cabinet is built of heavy asbestos board. Such construction reduces the radiation of heat from the outside of the unit, and greatly increases the power efficiency of the electric element.

Distinct advantages of the (Oven Type) Laboratory Dryer include highest possible capacity for the size of the unit, and proper ventilation to allow immediate discharge of moisture-laden air.

A maximum temperature rise of approximately 350 degrees Fahrenheit from room temperature in 20 minutes is possible on high heat setting. Switches give control of low, medium, or high heats.

For applications where heat control must be maintained, a thermostat can be supplied with the unit, with variable settings that will give the temperature range desired.

(Oven Type) Laboratory Dryers are wired for single-phase, 50/60-cycles, 110 or 220-volt current. In ordering, please specify size and exact voltage required. Three-phase wiring is not advisable, but can also be furnished.

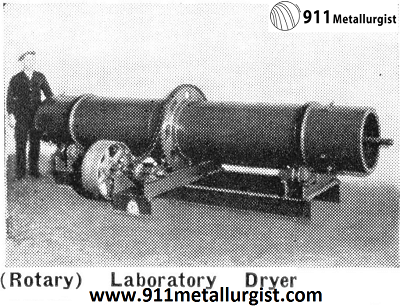

Rotary Laboratory Dryer

The (Rotary) Laboratory Dryer is a simple, inexpensive unit for use in continuous pilot test plants where it is necessary to reduce the moisture content of flotation concentrates, table concentrates or any other product of ore testing. This unit is also used to determine control factors for production purposes in continuous test plants operating on chemical or industrial products requiring drying or heating.

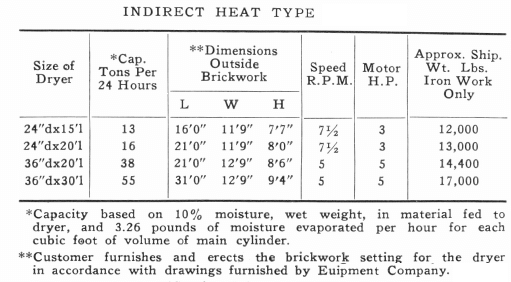

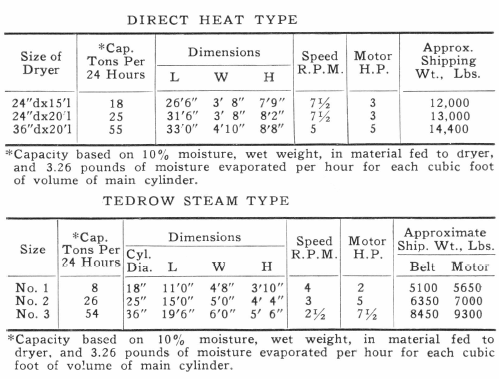

Three main types of (Rotary) Laboratory Dryers can be supplied. The direct heat unit is used when it is permissible for the drying gases to come in direct contact with the material being dried. Partition plates are provided which increase the heating surface. Drying may be by hot air or exhaust gases from other operations. If this drying gas has a deleterious effect on the product, then an indirect heat type dryer can be supplied. A further derivation is the Tedrow (Rotary) Laboratory Dryer in which steam is used as the drying medium.

Laboratory Dryer Capacity

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.