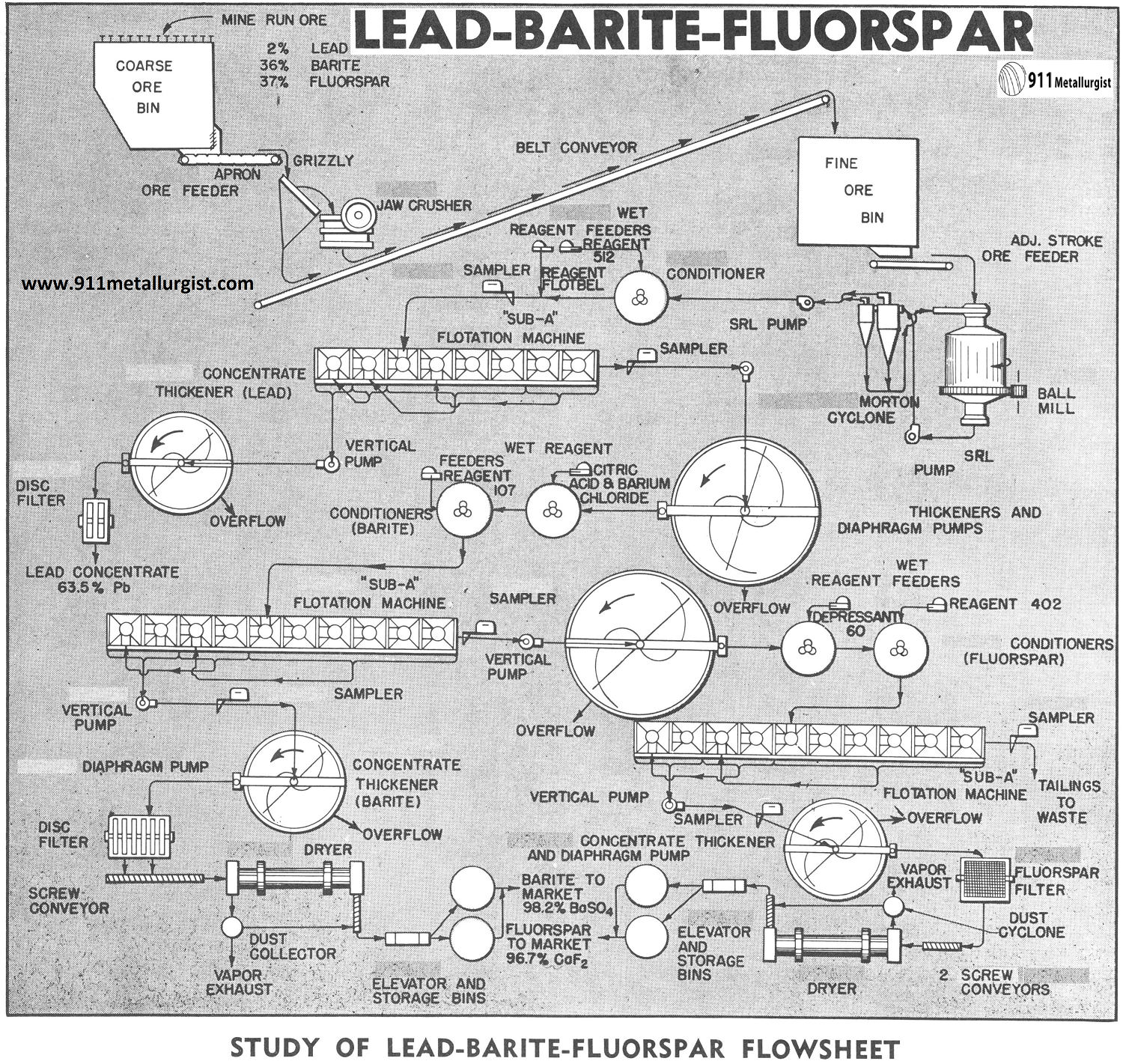

The concentration of fluorspar ores by flotation is well established but the treatment of lead-barite-fluorspar ores has long been recognized as a difficult process generally resulting in unacceptable concentrates with relatively poor recoveries. Intensive research on this problem is continually being conducted to develop favorable reagent combinations and conditions suitable for treating such ores. The problem discussed in this flowsheet study is based on successful laboratory tests for the treatment of a lead-barite fluorspar ore by flotation procedures to yield marketable concentrates. The ore to be treated contained approximately 2.0% Pb as carbonates, 36% barite and 37% fluorspar in a siliceous gangue with a small amount of calcium carbonate. Subsequent to the tests a concentrator was constructed and only minor modifications in the flowsheet were required.

Process Flowsheet and Treatment

CRUSHING

For the average small mills up to 100 tons per day, primary crushing is usually sufficient. Larger tonnages will require primary and secondary crushing for maximum efficiency in size reduction and subsequent grinding operations. The above flowsheet study is based on the treatment of 100 tons per day.

Grinding

The lead-barite-fluorspar ore requires grinding to 100 mesh for economic liberation of the minerals. Grinding is conducted in a Steel Head Ball Mill operating in closed circuit with a Morton cyclone classifier. The overflow, minus 100 mesh, passes to the lead flotation section. The high density underflow from the cyclone is returned to the ball mill for regrinding.

Flotation of Lead

The cyclone overflow passes to a conditioner with reagent 512 added to the conditioner to activate and collect the lead minerals. The conditioned pulp is subjected to rougher flotation with a small amount of Flotbel frother. The rougher concentrate is cleaned twice. The flotation tailing passes to a thickener to densify the pulp and remove excess reagents prior to the barite section.

Flotation of Barite

The thickened pulp from the lead flotation section is subjected to two-stage conditioning for the depression of the fluorspar and gangue constituents in the first conditioner using citric acid and barium chloride. The activation of the barite in the second conditioner is obtained by the use of reagent 107. The conditioned pulp is subjected to rougher flotation with two-stage cleaning of the rougher concentrate using a small amount of citric acid in the cleaner circuit.

The flotation tailing is then pumped to a thickener for reagent removal and pulp densification prior to fluorspar conditioning and flotation.

Flotation of Fluorspar

The thickened tailing from the barite section is subjected to two-stage conditioning in order to effect depression of the gangue in the first conditioner using depressant 60. The second stage of conditioning is for the activation of the fluorspar with oleic acid emulsified with reagent 402. The conditioned pulp is floated to produce a rougher concentrate which is then cleaned twice.

In some instances it is necessary to heat the pulp in the fluorspar section for more effective separation.

Thickening and Filtering

The thickening of the flotation concentrates offers no special problem. The thickeners are of sufficient capacity to adequately handle the tonnage and provide ample storage capacity during any interruption of the filtering and drying sections. Fluorspar and barite concentrates have a tendency of building up on the thickener surface, but this can be taken care of by retaining rings near the overflow lip, so that only clear water overflows from the thickener. Sprays are helpful in breaking the froth on the thickeners. The thickened concentrates at 50-60 percent solids are removed by Adjustable Stroke Diaphragm Pumps and fed by gravity to the filters. The lead and barite concentrates are dewatered by disc filters and the fluorspar by a drum type fluorspar filter.

Concentrate Handling

The filtered lead concentrate drops into bins. The barite and fluorspar pass to rotary dryers provided with dust collecting systems.

The dried products go to air tight surge bins for bagging or storage bins for loading into hopper cars.

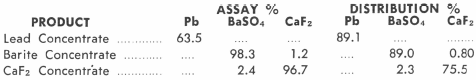

Metallurgical Results

The assays and recoveries obtained in the testwork are:

The approximate quantities of reagents and selection of reagents can be determined by batch testing but actual plant operation is needed to determine the actual reagent consumption and cost. The reagents used in the treatment of this ore were developed by Float-Ore Ltd., England.

Large Tonnage Mills

Flotation Machine Capacity—Generally a No. 21 (38×38) “Sub-A” for fluorspar is adequate for 200 to 300 TPD, new feed at 25 to 30% solids. On the basis of 300 tons per day at 25% solids and 3.0 specific gravity ore this figures out to 167 GPM of pulp. Generally on the No. 21 machine of the cell-to-cell type with 5″ feed pipes it is best to restrict the volume to 200 GPM or less. Actually a much higher volume can be handled, but then the efficiency of the cell drops off as the impeller becomes flooded. In some cleaning circuits the CaF2 is extremely fast floating, but in order to do proper cleaning it is best to restrict the flow in order to get the proper cleaning action. If the entire mass of solids is allowed to pop right to the surface, very little or no cleaning is obtained. So, the operator should not be misled into thinking he can get a tremendous capacity through a cleaner cell. When handling rougher froths and recleaner froths sometimes it has been necessary to increase the speed slightly in order to get more pumping action from the impeller. In some cases the cells with the return feed pipes have been speeded up as much as 10%.

At one mill treating approximately 200 tons of fluorspar ore per day, an 8-cell No. 21 rougher is used but they are adding another 2-cell No. 21 on the end as scavengers. They use a 10-cell No. 21 for cleaning 3 times (4-3-3 combination). They produce 100-120 tons per day of acid CaF2. Flotation feed into the roughers is approximately 35% solids. They are getting about the maximum production which can be expected out of a No. 21 circuit as their ore is fairly high grade. Recirculation of middlings is a big factor in any of these systems and must be taken into account.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.