To determine by fire-assay the percentage of lead in:

(a) The sulphide. Galena (PbS).

(b) An oxidised ore containing Cerussite (PbCO3), Anglesite (PbSO4), etc.

(a) The sulphide, Galena

Methods employed. Regarding the methods employed authorities vary widely ; here two methods are given for sulphide ores, the Soda and Argol (or Nail) method, and the Cyanide method.

The reactions are expressed as follows—

7PbS + 8NaHCO3 = 4Pb + 3(Na2S,PbS) + Na2SO4 + 4H2O + 8CO2

Na2S,PbS + Fe = Pb + Na2S + FeS

PbS + KCN = KCNS + Pb.

First Method (Soda, Argol and Nails).

Apparatus.—The wind furnace, pulp scales, crucibles, etc.

Reagents.—Soda, carbonate of potash, argol, salt, nails or wire.

Details of Operation.—The ore (clean galena) is reduced, sampled, and an assay sample obtained which has passed through an 80 sieve.

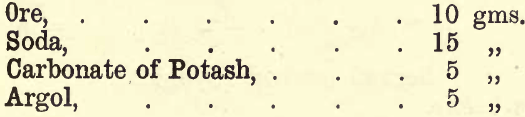

Weigh out in duplicate the following charge—

Thoroughly mix the charges on glazed paper, and transfer them to their crucibles (F). In each crucible insert two loops of fencing wire, tied together at their bends with iron wire, and of such a length that they come to about a quarter of an inch from the top of the crucible. When the loops are inserted add a cover of 5 to 10 gms. salt. Carefully bed the crucibles in a good coke fire, and build the coke well above the top edges of the crucibles. Place covers on the crucibles and a few lumps of coke on the covers.

Keep the fire between dull red and bright red (that is, a red), and never let it rise above a bright red. The time of fusion varies with the fire and ore, but at the end of ten minutes the cover may be removed and the charge inspected now and then, replacing the cover and coke after inspection. When frothing ceases, allow the charge to remain in the furnace for five minutes. Then pour into a hot, greased conical mould, after withdrawing the wire loops, any adhering prills of lead being removed by washing the wires in the slag. If the top edges of the crucible have cooled below a red heat the charge should not be poured. The button is in this case removed by breaking the crucible when cold.

Detach the slag; hammer the button into a cube and weigh it. Note the result and all details of firing, etc.

Calculation of Results.—The percentage is obtained by multiplying the weight of the button in grams by ten.

Accuracy of Results.—A difference of opinion exists as to the merits of this and of the Cyanide methods. Neither is as accurate as the gravimetric estimation. With a fairly clean Galena both methods give results with an error + or – of one unit, e.g. if the gravimetric process gives 75% of lead, these processes will give from 74% to 76%. On the whole, the evidence is slightly in favour of the Cyanide method, but before proceeding further the student must continue his practice till his results are uniform and satisfactory. Even if he has to run through thirty or more assays, the time so employed is amply repaid by the confidence gained.

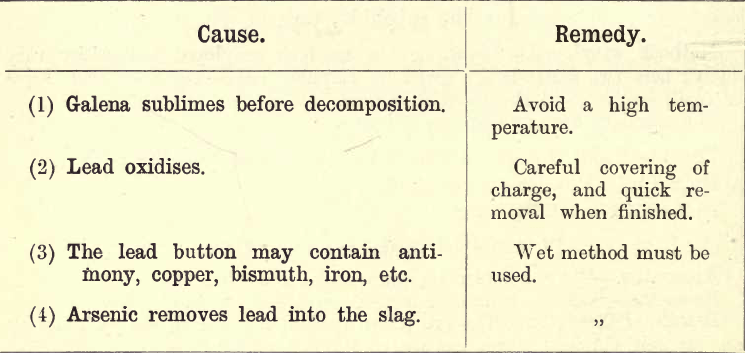

The following tabulation indicates the causes of inaccuracy:—

Briefly, the fire-assay of lead is unreliable when other reducible metals are present, and when these are absent it is accurate to about one unit on rich ores.

Second method (Cyanide).

Apparatus.—As before.

Reagents.—Potassium cyanide salt.

Details. -Weigh out in duplicate the following:—

Ore,………………………………………………….10 gms.

Cyanide,…………………………………………..30 gms.

Salt cover………………………………….about 5 gms.

Mix charge, cover and insert in the furnace as usual. Fuse for 15 minutes between a red and a bright red, firing as before. Pour and weigh the buttons.

Calculations.—As before.

Accuracy of Results.—Here again practice and care are necessary. With a clean rich galena good results are obtained, but when impurities such as copper, antimony, bismuth, etc. are present the results are worthless. To prove this statement, let the student add to one of his charges either antimony or copper, and then examine the resultant button. From this the student will gather that before assaying a strange lead ore, he must examine it qualitatively for these or similar substances. If these be present to any extent, fire methods must be replaced by wet processes.

(b) Oxidised Ores containing Carbonates and Sulphates of Lead.

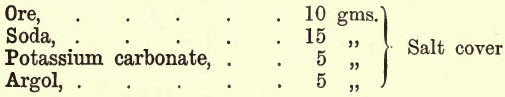

Method.—For carbonates the following charge serves:—

But where sulphates are present the Cyanide method is preferable; in fact, for both classes of ore, when fairly pure, this latter method is both simple and accurate.

Details of the operations need not be repeated. Let the student weigh out four charges,—two of the charge just given, and two of the cyanide charge as previously given. Fire carefully, and compare the results.

In conclusion, the student is reminded that practice and careful observation are necessary before success can be obtained. Where unsatisfactory results are obtained, the student should see that—(1) The ore is ground sufficiently fine; (2) That the fluxes are well mixed with the ore, intimate mixture being necessary; (3) That with every assay he note the state of the fire, the time that elapses before the charge fuses, the time of ‘frothy’ fusion, the time of tranquil fusion; (4) That he examine qualitatively the lead button and determine what foreign ingredients are present; (5) If results are low, examine the slags for lead.

By these and other tests the source of error may be located, and from the nature of the error the student will see whether his work is at fault, or, as may be, the case, that the Fire method is unsuitable to the ore in question,. It is only by taking pains that the student can arrive at any certainty as to the value of his work, and without certainty an assay is of little value. The student has not the time necessary to fully check all his operations, but wherever reasonably practicable he should make some attempt in this direction, and also should consult reference works on such points.