Fisher-Monarch Melting Furnaces

(Fisher-Monarch) Melting Furnaces efficiently melt brass, bronze, copper, aluminum, gray iron, ferro-manganese, gold and silver precipitates, and can also be used for smelting and refining grindings, borings, wash metals, and various ores. No crucibles are used. These furnaces are similar in construction, having chambers split longitudinally and hinged on one side so that they may be easily opened to replace linings. Charging and pouring openings have hinged lids and vents. A low pressure burner is provided for each unit or at opposing ends on each chamber of the double chamber type. Either gas or oil burners can be supplied and fuel can be oil, natural gas, city gas, or producer gas. Air pressure and volume required will vary according to the duty of the furnace. These units are of durable construction and simple to operate. Initial installation and operating expense is comparatively low and a range of capacities are available to meet the need of practically every size plant.

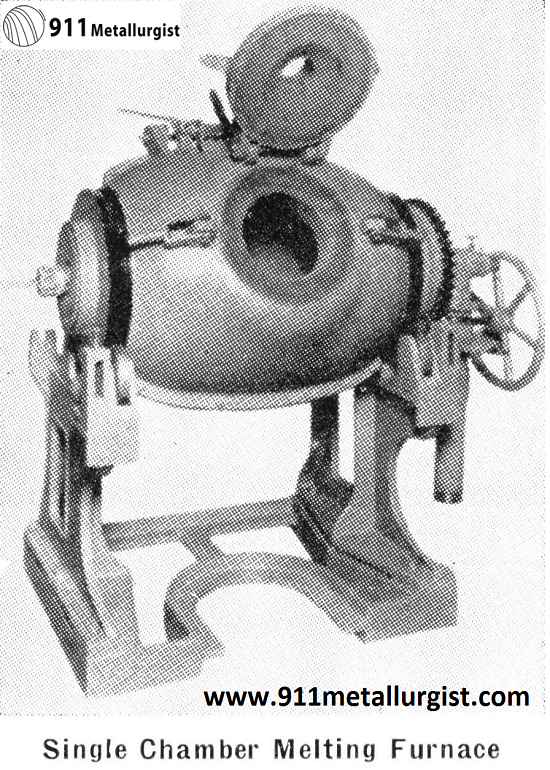

The Single Chamber Melting Furnace is so constructed that the metal is melted directly on the lining. The shape of the furnace lends itself particularly to the refining of precious metals as there are no corners in the lining in which the metal can collect. This low capacity furnace, up to 250 lbs. per heat, is ideal for small cyanide or other plants where a larger furnace is not needed.

This unit consists of an egg shaped, lined, metal shell or chamber mounted horizontally on two undercut stands which set on a cast iron base as a unit. The chamber revolves freely on rollers actuated by a worm gear and handwheel. A 5-inch thick lining of Carbofrax No. 3 (Silica) is supplied as standard. The diameter of the chamber is 17 inches and the diameter of the charging opening is 9 inches.

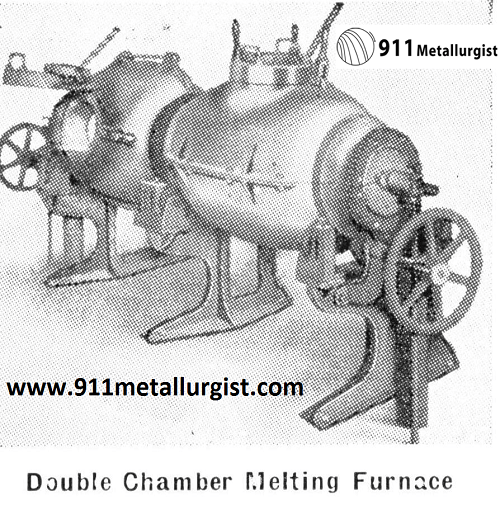

The Double Chamber Melting Furnace is really two of the Standard Single Chamber Furnaces in one. It is two chambers with each chamber consisting of an egg shaped, lined, metal shell. The chambers are mounted horizontally in line on a structural steel base as a unit. Each chamber is revolved independently by means of a worm gear and handwheel.

In operation, a chamber is preheated, charge is introduced, and the burners are then fully opened to complete the melting and refining operation. The waste heat and gases pass through the second chamber. This action preheats the second chamber and, a charge can be placed in the second chamber for melting while the refining proceeds in the first chamber. Thus, operating procedures can be alternated, providing additional use of the hot gases in pre-heating and alternate charges. The economy of this method is self-evident as melting is practically continuous. As this unit consists of two Single Chamber Furnaces incorporated into a single unit, general specifications are the same as for the Single Chamber Melting Furnace.

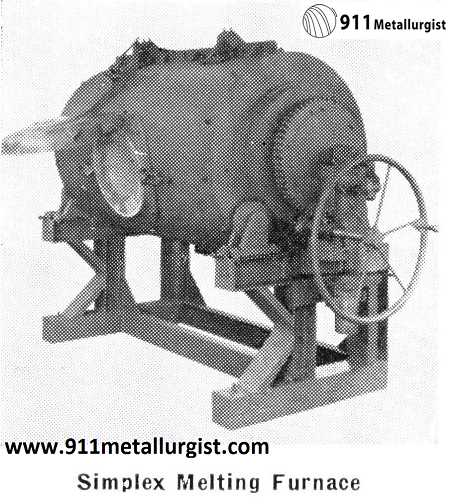

The Simplex Melting Furnace ranges in capacity from 500 lbs. to 6,000 lbs. This capacity makes it suitable for the larger cyanide or precious metal recovery plants. The melting process in this furnace is accomplished by radiated heat with no flame striking the metal directly.

The Simplex Melting Furnace is made of steel plate with cast iron heads and with a cast steel collar around the pouring opening. It is equipped with a lined cast iron door which clamps down tight on the steel collar when the furnace is in operation, and is easily manipulated by means of a lever located at the rear of the furnace. The chamber rests on undercut cast iron stands which are bolted to a heavy bed plate. The furnace revolves easily on steel rollers, actuated by means of a handwheel driven worm and gear.

A Carbofrax No. 3 (Silica) lining, varying in thickness according to the size and capacity of furnace, is furnished as standard. Other lining materials may be used, however, and lining the furnace is a very simple operation. If desired, a lining of fire clay tile can be used. Full instructions for lining are furnished with each furnace.

If manual oscillation is impractical, such as on the larger capacity furnaces, a motor driven oscillating device may be furnished. Also, furnaces are available with power drive controlled by push button or automatic controls.

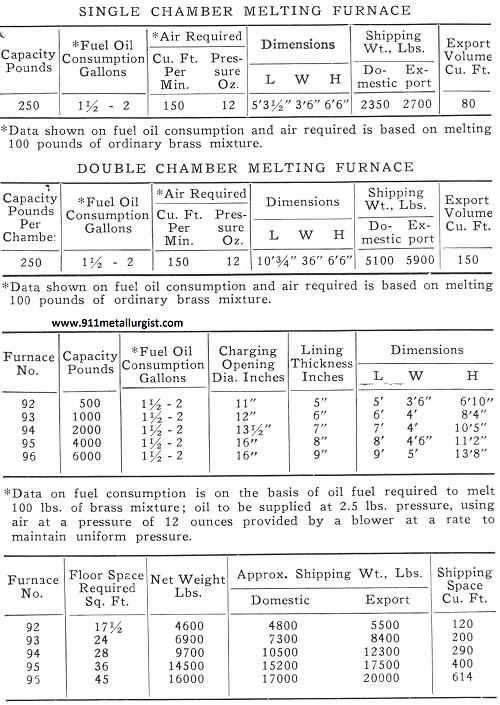

Melting Furnace Capacity

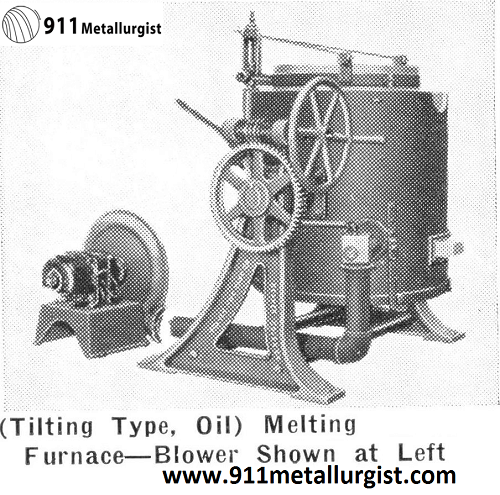

Tilting Melting Furnace

Tilting Melting Furnaces have been designed for melting gold and silver bullion, cyanide precipitates, brass, copper, and other non-ferrous metals. The patented linings are made of the most refractory fire clay, give maximum support to the crucible in all positions, and insure uniform distribution of heat. These furnaces are equipped with drop bottoms, a great convenience in cases of spillage.

The standard furnace is supplied with a low pressure oil burner and motor blower, but it can be furnished with a high pressure burner or a gas burner. If no electricity is available, a belt driven blower can be supplied. The complete furnace includes a low pressure burner, a black lead crucible, a 30 gallon oil tank, air and oil pipes, and fittings.

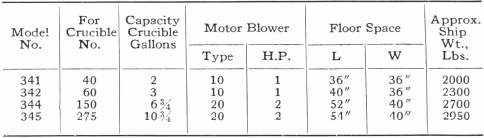

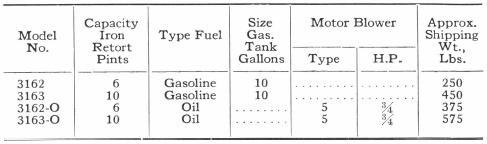

Melting Furnace Capacity

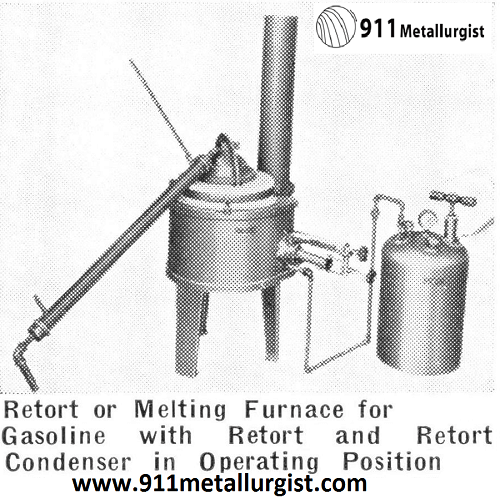

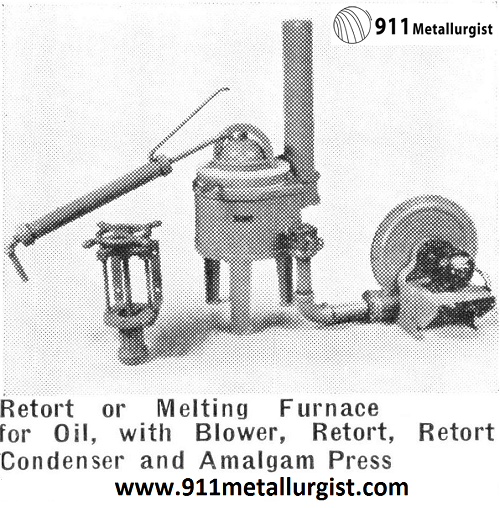

Gasoline – Oil Retort or Melting Furnace

Retort or Melting Furnace is made in two standard sizes and can be supplied for burning gasoline or fuel oil. The retort furnace includes all furnace parts shown in the illustrations except retort, condenser, and amalgam press. The oil-fired furnace includes a burner, motor blower, oil tank, pipe fittings, and one length of clay-lined stack. The gasoline furnace includes a burner, blow-pipe tank, pipe fitting, and one length of clay-lined stack. These Retort or Melting Furnaces are also furnished as either oil or gasoline fueled melting furnaces.

The Retort Condenser is made of iron with a water jacket. The inner tube is threaded to the retort outlet. This unit is very useful in mercury retorting and minimizes the danger of mercury poisoning. Tube diameters are 1¼”, 1½”, 2″, and 2½”;

weights 10 lbs., 11¼ lbs., 13 lbs., and 16 lbs. respectively. The Amalgam Press, shown in the illustration, is used for pressing excess mercury out of amalgam. Details on this accessory are given under, “Amalgam Press.”

Furnace Capacity

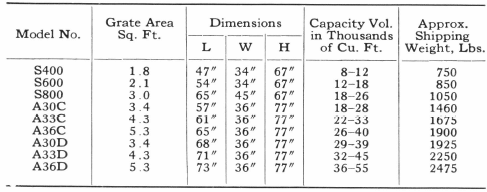

Not Melting but Heating Furnace

The Heating Furnace incorporates many developments in modern warm air heating systems. This unit is one of the heaviest steel furnaces built and is ideal in any mill, ventilating as well as circulating warm air.

The furnace is made of ½” copper – bearing steel boiler plate, solidly riveted and welded in one permanent, absolutely gas-tight unit which will render continuous and economical operation. It has an extra large and effective heating surface and a long double flue gas travel which provides extra heat at small fuel cost.

Heating Furnaces heat immediately and unlike steam or hot water heating plants are not susceptible to freezing or other similar inconveniences. They can be fueled with either wood, coal, gas or oil.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.