Here is described the essential features of the Merrill Crowe Process and its equipment/apparatus used for the Simultaneous Clarification, De-aeration and Precipitation of cyanide solutions. Limited space has prevented a full description of all of the details involved but we have pointed out the application of the various types of equipment and the advantages to be expected, and where practical have included the essential operating features.

The Merrill-Crowe Precipitation Process, embodying the Simultaneous steps of Pre-Coat Clarification, De-aeration and Precipitation for the recovery of gold and silver from cyanide solutions is now almost universally used throughout the world. It appears in the flow sheets of all new mills and in addition has been adopted by most of the older plants effecting substantial savings in labor and reagent cost, and resulting in more efficient precipitation and higher grade bullion. The description which follows indicates how these results are obtained with the several different types of equipment.

Enquiries and requests for quotations should specify the location of property, t he nature and tonnage of the material to be cyanided, the tonnage of solution to be precipitated daily, and whether the values to be recovered are principally gold or silver; also whether appreciable amounts of copper are likely to be present in the solution. Where available, a drawing showing the general arrangement of the mill in plan and profile will enable us to suggest the most suitable form of equipment. Charges for Process Rights and Equipment are based upon the above figures, and prices and estimates will be furnished promptly upon receipt of the necessary information.

he nature and tonnage of the material to be cyanided, the tonnage of solution to be precipitated daily, and whether the values to be recovered are principally gold or silver; also whether appreciable amounts of copper are likely to be present in the solution. Where available, a drawing showing the general arrangement of the mill in plan and profile will enable us to suggest the most suitable form of equipment. Charges for Process Rights and Equipment are based upon the above figures, and prices and estimates will be furnished promptly upon receipt of the necessary information.

In Modern Milling Processes, Cyanidation may be practiced in a variety of ways. Most frequently Encountered is the “All Slime” plant, grinding in cyanide solution followed by thickening. Continuous series agitation and continuous slime filtration, either single or double stage, depending upon ore grade. Of less frequent application is the practice of separating the more sandy portions of the ore for gravity leaching as in the older plants on the Rand, in The Mysore Field in India, and at The Homestake in South Dakota. Where the necessity for thorough air oxidation of certain constituents of the ore render this treatment particularly effective. If amenable to flotation, the ore may be ground in water and floated, with subsequent cyanidation of the concentrate only, as at McIntyre and Pamour in Ontario, and in Australia where the concentrates are roasted prior to cyaniding. However, not many gold ores will yield a satisfactory tailing by flotation alone and consequently both tailings and concentrates are separately cyanided. In all of the above flow sheets, where the ore contains appreciable amounts of free gold. Various devices are used to recover as much as possible of the metal in the grinding circuit; hence the use of blanket strakes, riffles, traps or jigs in many gold mills.

However for precipitating or recovering the metallic values from cyanide solutions, no method has yet been found to compete successfully with the Merrill-Crowe Process in which the metals are precipitated on zinc dust immediately following Simultaneous Pre-Coat Clarification and De-aeration, with substantially complete removal of suspended solids and colloidal precipitates, and of dissolved oxygen.

In Africa and India a few of the older mills still use zinc shavings for the precipitation of gold but in Africa particularly, these plants are gradually changing over to the more effective Merrill-Crowe Process.

Sodium sulphide precipitation of silver at cobalt, Ontario, and charcoal precipitation of gold at Youanmi, Australia, were both used successfully for a time but did not prove applicable elsewhere. Precipitation of silver on aluminum dust was also practice at Cobalt but while attempted at several other large plants in Mexico and South America, was discontinued owing to difficulties in filtering and melting, caused by the formation of calcium aluminate in the solutions. Electrical precipitation has been repeatedly tried but power and operating costs are prohibitive and a “barren” tail solution cannot be obtained.

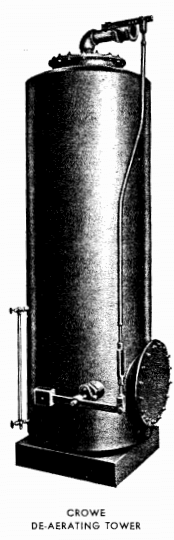

The efficient precipitation of cyanide solutions with zinc dust is dependent upon two essential preliminary or conditioning steps, namely, thorough clarification and the removal of dissolved oxygen. By thorough clarification is meant not merely removal of suspended ore slimes, such as are plainly visible to the naked eye, but also the more harmful colloidal hydrates of aluminum, iron and magnesium, which form and precipitate out in most pregnant solutions, particularly on standing for any appreciable length of time. To remove such deleterious solids the Merrill-Crowe Process uses submerged vacuum leaf filters of improved design and equipment for Pre-Coating the filter surfaces with diatomaceous silica. The outlet of the clarifying filter is connected directly to the Merrill-Crowe De-aerating tower, so that immediately after thorough clarification and partial de-aeration, the solution enters the main vacuum chamber, where the removal of oxygen is completed.

The chemical reaction involved when gold is precipitated by metallic zinc is essentially one of reduction by nascent hydrogen which is formed by the action of alkali cyanide upon the zinc. Most cyanide solutions resulting from the treatment of ores contain appreciable amounts of dissolved oxygen and if this oxygen were allowed to remain, it would immediately combine with the evolved hydrogen, increasing the consumption of zinc and cyanide with the formation of calcium zincate and other insoluble compounds of zinc and cyanide which seriously interfere with precipitation. The whole operation of precipitation and subsequent recovery of the precipitated metal is simplified and rendered more efficient by the simple expedient of mechanically removing this interfering element. In the Merrill-Crowe Process this is accomplished by passing the solution through suitable towers in which the solution is exposed in thin films to the action of a high vacuum. The decreased solubility of oxygen at low absolute pressure causes rapid evaporation of the oxygen, and cyanide solutions thus treated will usually contain no more than traces of oxygen.

Immediately following Clarification and the removal of free oxygen, the solution is contracted with finely divided metallic zinc, under conditions which preclude the reabsorption of oxygen. This results in maximum efficiency of the precipitant since no hydrogen is wastefully consumed in combining with dissolved oxygen.

The mixture of precipitated metals and zinc dust is collected on a suitable filter, so designed that a uniform layer of precipitant is deposited over the whole filter surface, whereby each particle of solution is brought into intimate and equal contact with the precipitant. The accumulated precipitate of gold and silver is periodically removed for melting and refining and the precipitated or barren solution is returned for re-use in the milling process.

As distinguished from zinc shavings precipitation, a complete recovery of the precipitated values is made at each clean-up. With gold solutions, the values returned to the boxes with the washed shavings usually approximate one-half of the gold cleaned up; with silver the absorption in the boxes is less but in neither case can it be prevented without excessive consumption of zinc and chemicals. The loss in interest on values thus continually held back is a direct charge against the old shavings process. All operators will, of course, appreciate the advantages of the complete clean-up of the Merrill-Crowe Process as a means of checking bullion production against ore and solution assays. Frequent and complete cleanups are of course particularly desirable in mills which handle custom ore. The compactness and flexibility of the plant effects a marked saving in floor space and building construction and in addition, in the colder countries such as Northern Canada, a considerable economy in heating during the winter months.

The Merrill-Crowe Precipitation Process is now almost universally used in Cyanide plants throughout the world. Whether for the treatment of silver ores in Mexico, for gold ores in the rapidly developing districts of Canada or on the Rand, the most important gold mining area of the world, the Process will be found in operation. In the latter district, the total amount of solution precipitated by the Merrill-Crowe Process, approximates 200,000 tons per day. One mill, Randfontein, accounts for 20,000 tons of this solution. In many of the older plants, zinc shaving boxes have been dismantled to be replaced with the Merrill-Crowe Process, and in designing new plants, metallurgists on the Rand, and in fact throughout the world, have, almost without exception, embodied it in their flowsheets.

Types of Equipment Used in the Merrill-Crowe Process

To users of the Merrill-Crowe Process we offer three different types of equipment the choice of which is dependent upon the size of the plant, that is, upon the nature and quantity of the metals to be precipitated, and, lastly, upon the preference of the individual operator. General arrangement of the milling plant may also be determining factor. There is some variation in first cost of the three types but all are substantially equal in operating costs and in metallurgical efficiency. Each type, the equipment used for Simultaneous Pre-Coat Clarification and De-aeration is identical as will be noted in the drawings and description which follows. It is only in the filters used for collecting the Precipitate that the three types differ. Each type takes its name from the Precipitate filter used, that is, “Filter Press Type,” “Bag Filter Type” and “Vacuum Leaf Filter Type”.

The filter press type has the most general application and with the recently developed improvements in Clarification, is preferred by most operators. Except for small plants the cost of the Press Type is not appreciably greater than the Bag Type and is considerably less than for the Vacuum Leaf Type which is used principally in large plants or under exceptional conditions where the larger filter area provided is particularly advantageous.

FILTER PRESS TYPE Merrill-Crowe System

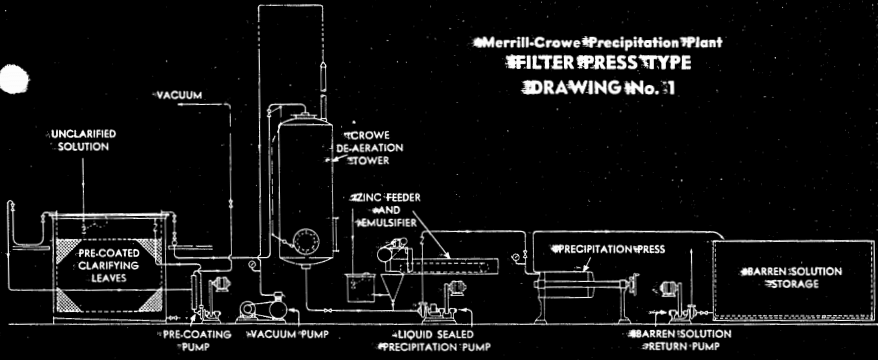

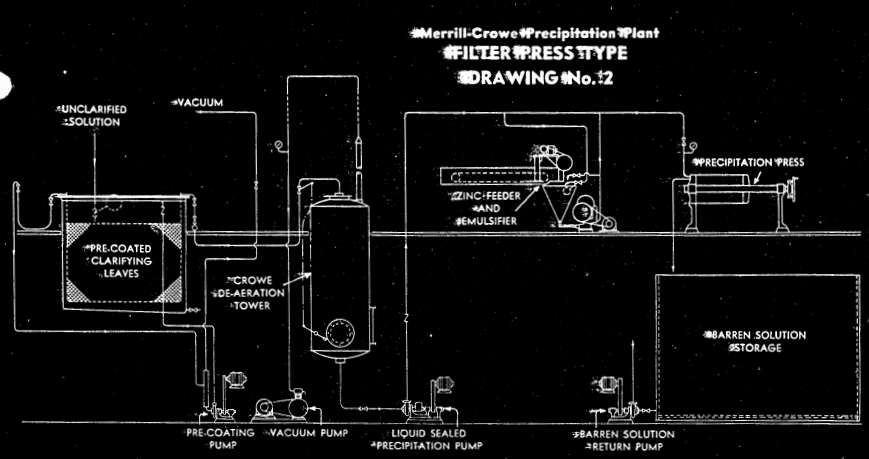

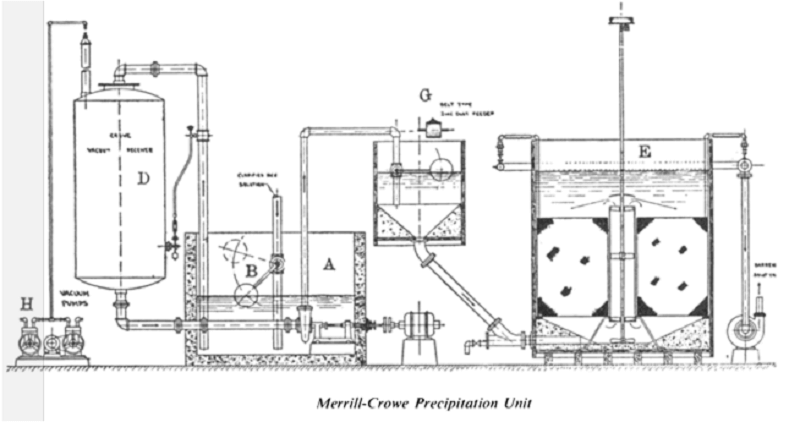

The equipment used for the simultaneous clarification, De-aeration and precipitation of cyanide solutions using Pre-coated clarifying leaves and filter presses for collecting the precipitate is shown in Drawings No. 1 and No. 2, which represent two of the arrangements most frequently used.

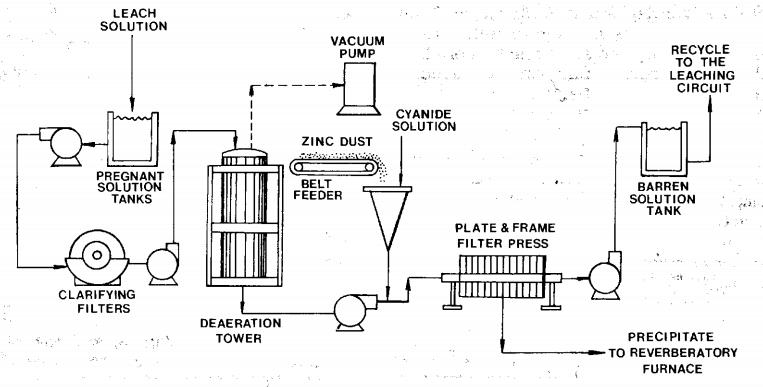

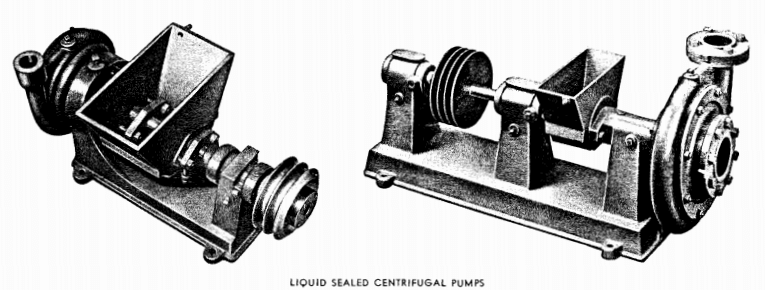

In each case a single, liquid-sealed centrifugal pump is used to effect the passage of the solution through the successive steps of clarification, de-aeration and precipitation. The clarifying tank is kept filled to a constant level with unclarified gold-bearing solutions, the inflow to the tank being controlled by an automatic float valve as in Drawing No. 1. Alternatively a shallow tank may be used with provision for constant overflow. This overflow may be surplus primary thickener overflow going to mill storage or solution from the pregnant storage tank pumped to the clarifier with surplus overflow returned to storage. Suspended in the clarifying tank are the vacuum clarifying leaves with outlets connected to a manifold which in turn is connected to the top of the vertical Crowe vacuum tower in which final de-aeration of the solution is affected.

Rectangular steel clarifying tanks have now come into quite general use and these tanks are built with a separate compartment in which the individual filter elements are pre-coated with a thin layer of diatomaceous silica as a filter aid. The filter leaf, after washing, is immersed in the pre-coating compartment to which has been added a small amount of the pre-coating material, kept in agitation with compressed air. By means of a flexible hose the leaf is attached to the suction side of a small self priming centrifugal pump, which withdraws solution through the leaf, depositing the filter aid on the filter fabric, and returning the effluent to the tank. After pre-coating the leaf is lifted, returned to its operating position in the clarifying tank and again connected to the discharge manifold. Throughout the transfer and re-immersion continuous vacuum is maintained on the leaf so that the layer of filter aid is not detached or disturbed, and after re-immersion, circulation through the leaf is continued until the effluent is perfectly clear, when the valve leading to the manifold is opened and regular operation resumed. Thus any imperfection in clarification is readily detected and solution is not passed on to the subsequent steps of de-aeration and precipitation until perfect clarity is assured.

Inflow of solution to the Crowe tower and consequently by an automatic float valve. Within the tower the solution passes down over suitable grids which break up the flow into small streams and films, thus effecting the substantially complete removal of dissolved oxygen. The top of the de-aerating tower is connected with a dry vacuum pump which maintains a high vacuum within the tower and removes the air released from the solution. Clarified deaeration solution is withdrawn from the bottom of the tower by a single stage centrifugal pump, liquid-sealed to prevent re-entry of air through the pump gland.

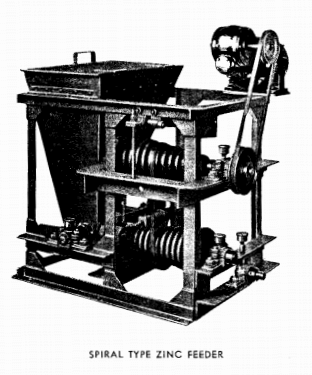

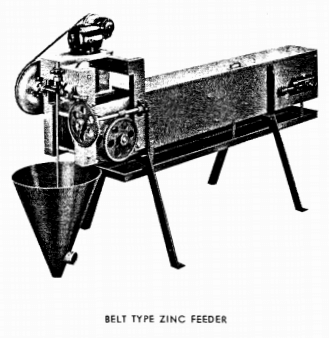

A belt type zinc feeder with integral motor drive discharges as regulated amount of zinc dust into a mixing cone supplied with a suitable solution, preferably barren solution from a small float controlled steady head tank. A liquid reagent feeder supplies a continuous and uniform feed of soluble lead salt preferably lead nitrate, for activating the zinc. This feeder may be positioned to discharge into a steady head tank or to the clarifying tank, the choice being governed by the nature of the solution to be precipitated.

Drawing No. 2 shows the activated zinc emulsion being forced into the main solution line entering the press by means of a small triplex pump. Alternatively, as in Drawing No. 1 the outlet of the emulsion cone is controlled by a mechanically operated valve by which zinc emulsion, at regular intervals, is introduced directly into the suction of the main solution pump and hence into the precipitation press.

The filter presses now used in the Merrill-Crowe Process are of conventional design with square containers and with closed discharge, which not only avoids splash and frequent discharge cook renewals but also makes it possible to elevate the barren solution several feet above the level of the press and so discharge directly into a barren solution storage tank placed on the same level.

The construction of the new Merrill Crowe Clarifying Leaf. Circular wood splines are firmly mounted in the wood header and lower perforated drainage pipe. These filters are usually operated with sheeting or light canvas cover only but an un-stitched burlap under cover is sometimes used.

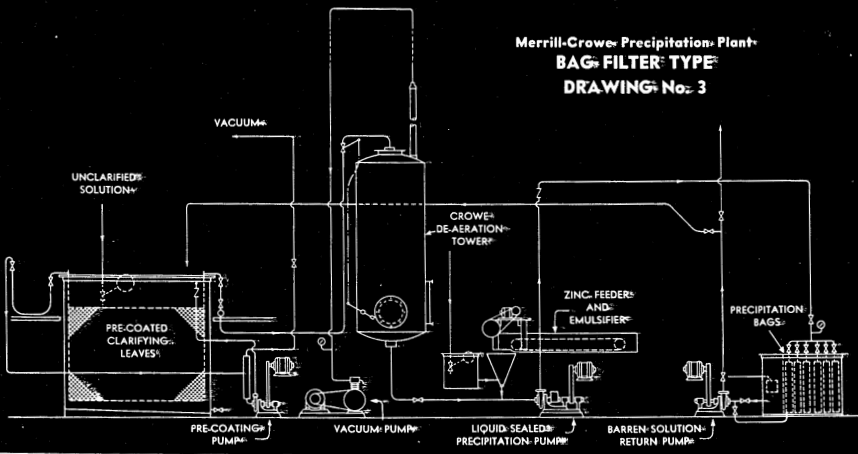

BAG FILTER TYPE Merrill-Crowe System

BAG FILTER TYPE Merrill-Crowe System

Drawing No. 3 shows the usual arrangement of equipment in a Merrill-Crowe Plant with Pre-Coat Simultaneous Clarification-Precipitation using Bag Type precipitate filters. These filters are particularly suitable where small solution tonnages are handled. With the recently developed Fitzgerald Bag Head the bag units are quickly assembled and with the duplicate set of heads provided, clean-up is effected with minimum loss of time. The bags are contained in a steel tank, provided with a locked cover to prevent tampering or theft, and a centrifugal pump with automatic float control elevates the precipitated solution to the barren solution storage. Alternatively, the barren solution may gravitate to the storage tank. Clean-ups is made by emptying the tank draining and blowing the bags with compressed air, and then disconnecting the bags and removing the inner filters containing the precipitate which is dried fluxed and melted in the usual way.

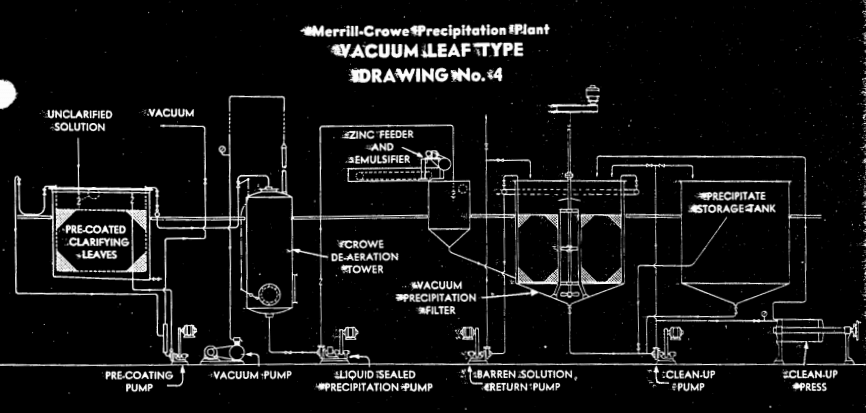

VACUUM LEAF TYPE Merrill Crowe System

General arrangement of a Vacuum Leaf Type plant is shown in Drawing No. 4. Clarified, de-aerated solution, withdrawn from the Crowe receiver by the liquid-sealed centrifugal pump, discharges into a steady head tank, to which is also added zinc from the precipitant feeder. The mixture of solution and precipitant enters the precipitation tank and is continuously circulated over the submerged vacuum filter leaves, the barren solution being withdrawn through the leaves by a centrifugal pump which in turn discharges to a suitable barren solution storage tank. Access to the precipitation tank is only required at a clean-up and, therefore, the tank is provided with a locked cover of heavy screen to prevent theft. When clean-up is made, the, precipitation tank is emptied and the precipitate washed from the leaves and transferred by pump to a settling tank. The bulk of the solution is decanted and returned to the precipitation circuit after which the settled precipitate is transferred to a small filter press for drying. Owing to the constant circulation maintained in a precipitate filter of this type, the filter surfaces are coated with a very uniform layer of precipitant which of course results in the highest possible precipitating efficiency. Without exception this is the equipment used in all of the, recently built cyanide plants on the Rand, and many similar installations have been made in other parts of the world. It is particularly suitable for large plants, especially where, as on the Rand, the gold precipitate is acid treated: also where a considerable, bulk of silver precipitate is to be handled.

|

|

|

Zinc Dust Precipitant in Merrill Crowe

With the high efficiency now developed by the Merrill-Crowe Precipitation Process, resulting in extremely small quantities of zinc used to precipitate the metals from solutions, it has become increasingly important to use a zinc dust of high metallic content and uniformity. Also the mesh of zinc dust should be as fine as practicable in order to obtain the maximum surface contact between the zinc and the solution. We know of no zinc dust that fulfills these requirements as satisfactorily as that manufactured by The Alloys Company, a subsidiary of the Merrill company. Constant research is maintained in an endeavor to supply precipitants best suited for use with the Merrill-Crowe Process.

This zinc dust was produced in San Francisco and is marketed under the trade-mark “Merrillite” Many of the principal cyanide plants of Canada, the United States, Mexico and other parts of the world use this zinc dust exclusively with entirely satisfactory results, and we have no hesitancy in giving our unqualified recommendation to this product for use with the Merrill-Crowe Process. In particular we advise its use in the initial operation of all new plants, because we know that MERRILLITE, being of well established uniformity and unquestioned high efficiency, will give dependable precipitation, thus avoiding the possibility of variations which may result from the use of other brands of zinc dust.

Above is shown the New Liquid Reagent Feeder used in the Merrill-Crowe Process for feeding lead nitrate or acetate. Also to supply a uniform strong cyanide drip when needed. Built of redwood and stainless steel with nothing to rust or wear out and supplied with or without reduction motor drive.

Below are shown two sizes of the Sealed Pumps used to withdraw de-aerated solution from the Crowe vacuum Receiver. These are supplied in several different types and in various sizes dependent upon the tonnage of solution to be handled.

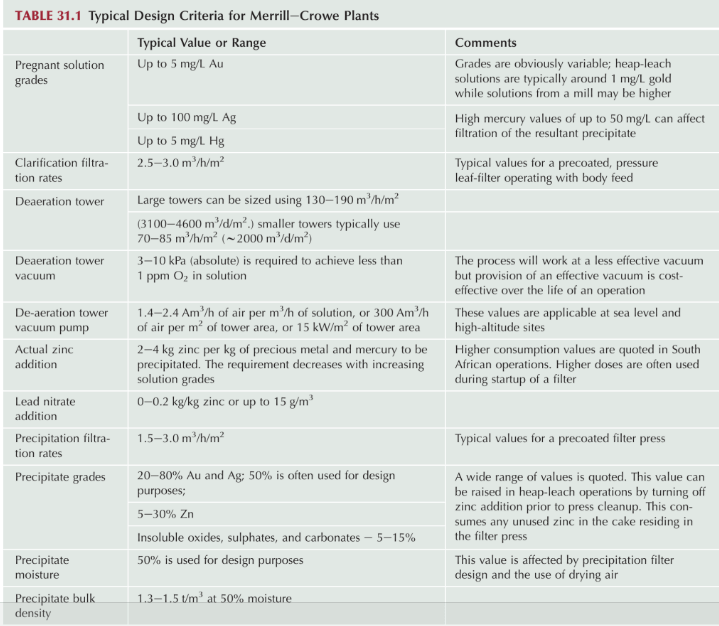

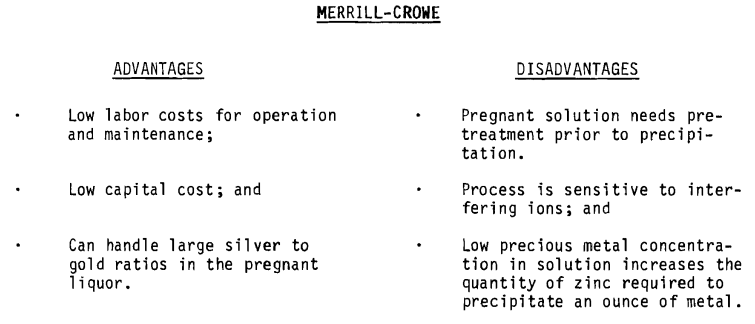

Zinc dust cementation, or Merrill Crowe precipitation is the most widely used method for gold and silver recovery. Because of its simple and efficient

Zinc dust cementation, or Merrill Crowe precipitation is the most widely used method for gold and silver recovery. Because of its simple and efficient

operation, the Merrill Crowe Process is currently used at the 10 largest gold producing mines in the free world, all of which are in South Africa. This process is attractive for use at new mines where the ore exhibits a high silver to gold ratio (ranging from 5:1 to 20:1). Ores with high silver values present significant problems to carbon adsorption circuits because the silver causes high carbon stripping requirements which may be economically prohibitive. Several of the existing operations using Merrill-Crowe precipitation actually experience higher silver recoveries than gold.

One other advantage to the zinc cementation system is that once dynamic equilibrium (steady state) is reached in the process plants, relatively few people are required for operation and maintenance (i.e., only simple valve operation and meter reading tasks are required). The process does, however, have some disadvantages. The leach liquor must be treated (i e., clarified and de-aerated) prior to precipitation. Indeed, as noted in a preceding section, inefficient pretreatment is detrimental to successful precipitation. Other disadvantages stem from the process being quite dependent on and sensitive to the pregnant liquor composition. Lower gold concentrations in the feed solution result in higher zinc consumption. This is because the zinc is mostly used to precipitate all of the other metals in solution before gold and silver are recovered. Also, interfering ions such as arsenic and antimony can be problematic, leading, in some cases, to the consideration of other recovery methods.

Zinc Precipitation in the Merrill Crowe Process

Portable Units/Shelf Units. Depending on the expected flow rate and the size of operation, Merrill-Crowe zinc precipitation units can come in a variety of’sizes. These range from 20 gallons ‘per minute (1.3 l/sec) in small self-contained units to 4,000 – 5,000 gpm (250 to 315 l/sec) throughput in custom plants. Smaller skid-mounted units are available from several suppliers. Each unit comes equipped with all the necessary pumps and piping. All the user must provide is a feed line to the unit, an effluent (barren) line out, and electrical supply. These units are very useful for ranges of flows from 50 to 250 gpm (3 to 16 l/sec). They are easily assembled or dismantled and often are mounted on trailers for easy transportation. However, beyond a certain point, it becomes apparent that the filtration supplied with these units is insufficient for optimum operation. The operator may spend more time cleaning the clarifier filters than actually treating solution. It is for this reason that operations are custom designed for handling large daily volumes of pregnant solution.

Custom Designed Merrill Crowe Process Units

Here the choice of size and volume throughput is not limited. Typically, the designs are based on an expected volume of

requirements , with a built-in over-design included. Stationary pressure filters, or the leaf-vacuum type, are incorporated as well as vacuum

deareators. Plate and frame presses are often a standard. Larger throughputs of these plants justify instrumentation such as turbidimeters or continuous flow (in-line) oxygen probe detectors to facilitate the operation and improve efficiency.

Disadvantages are inherent with the size of the plants. They are usually permanent installations and are expensive to relocate .

Merrill Crowe PART II

References: The Merrill-Crowe Process, Simulataneous: Pre-Coat Clarification, De-Aeration, Precipitation by Merco. THE MERRILL COMPANY ENGINEERS Zinc-dust cementation of silver from alkaline cyanide solutions analysis of Merrill-Crowe plant data Introduction to evaluation, design, and operation of precious metal heap leaching projects by Dirk J. A. Van Zyl, Ian P. G. Hutchison, Jean E. Kiel

Society of Mining Engineers, 1988