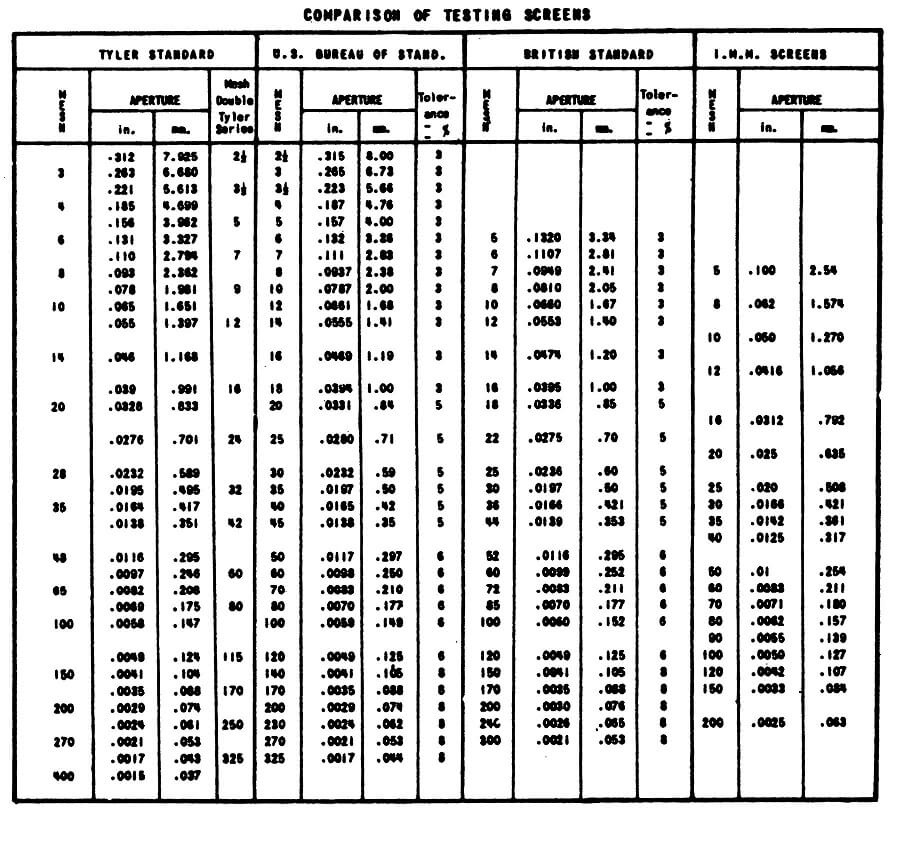

A Mesh to Micron Conversion Table can be made using this screen scale as its base with an opening of 0.0029 in. which is the opening in 200 mesh 0.0021 in. wire, the standard sieve as adopted by the Bureau of Standards of the U. S. Govt., the openings increasing in the ratio of the sq. root of 2 or 1.414 except in the sizes Nos. 65 to 200 which increase in the ratio of the 4th root of 2 or 1.189.

- The base of the Tyler series is the 200 mesh screen with aperture equal to .0029 inches or .074 mm. The ratio between apertures of consecutive screens is the square root of 2. For closer sizing a series of intermediate screens are available, the ratio between apertures of consecutive screens in the Double Tyler series being the fourth root of 2. Owing to manufacturing difficulties, no Tyler screens finer than 400 mesh are available. Tyler screens coarser than 2.5 mesh are available but are not numbered.

- The base of the U.S. Bureau of Standards series is the 10-mesh screen with 1.00 mm. aperture. The ratio between apertures of consecutive screens is the fourth root of 2.

- The ratio between apertures of consecutive British Standard screens is only approximately equal to the fourth root of two because wire diameters are limited to those occurring in the S.W.G. series.

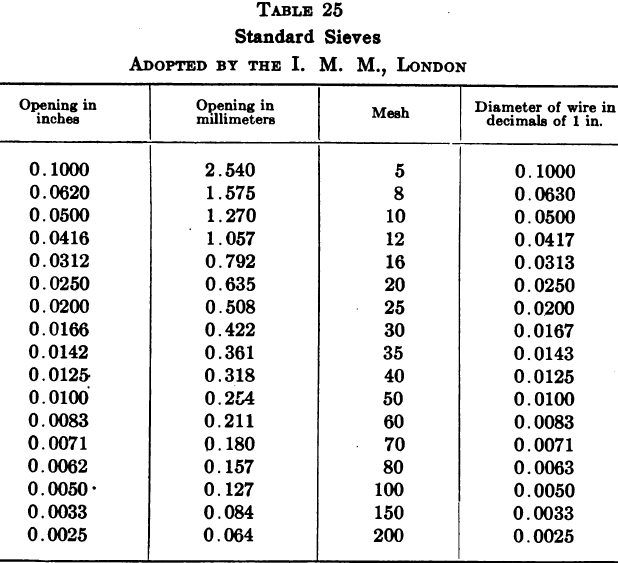

- In I.M.M. screens, wire diameter equals aperture and aperture in inches equals one divided by twice the mesh number.

- Adapted by D,C.G. from presentation in Chem. Eng. and Mining Review, June 10, 1940. Original source: Ore Dressing Laboratory of university of Melbourne.

Size and Mesh

The size of a piece of ore or of any of its products is usually defined by the length of the side of a square hole through which it will pass. Thus, if a lump of ore is stated to be of “ 2½-inch size ”, it means that it will just pass through an opening 2½ inches square.

The size of this 2½-inch lump could also be described as being of “ 3½-inch ring ”, meaning that it will just pass through a circular hole 3½ inches in diameter. Table 1 gives the corresponding square and ring sizes. In this volume the square size is used unless it is specifically stated that the reference is to ring size.

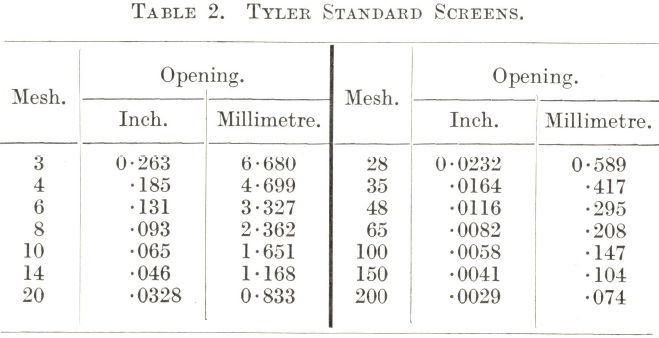

Below 3/8 in. it is usual to define the size of a particle by its “ mesh ” size, meaning that it will just pass through an aperture in a screen of that mesh. The Tyler Standard Screen Scale is generally adopted for the purpose and any reference to mesh in this book refers to it exclusively. Table 2 gives the sizes of the apertures of Tyler screens of various meshes. The use of the standard scale of the Institution of Mining and Metallurgy

London is being discontinued and the scale of the British Engineering Standards Association substituted, the latter being in close agreement with the Tyler standard screen apertures.

The method of describing the size of the ore, or of its products, as a whole at any stage of its treatment by means of a screen analysis is too well known to need explanation ; it should be understood that this is the only accurate way of stating the degree of comminution. A statement to the effect that the ore has been crushed to a certain size or mesh is apt to be misleading, since it cannot be taken for granted that it means that the whole of the material has been reduced to that size ; thus, to say that an ore has been crushed to 100 mesh nearly always implies that the product of the operation contains up to 10% of oversize on 100 mesh. Since no standard convention exists, a reasonably explicit statement of the size is advisable if accuracy is required, as, for instance, that a product contains 5% of plus 100 mesh and 80% of minus 200 mesh material.

In the operation of dry crushing, the fine portion of any product is referred to as FINES. In the wet grinding and subsequent sections, that part of the ore which is so fine that it remains in suspension in the water is termed SLIME, the remainder being classed under the general heading of SAND.