Table of Contents

Grinding costs are an important item in cement manufacture, and the cost of power is one of the large items in grinding costs. Even where power is of secondary importance, cost items dependent on mill capacity are influenced by the efficiency with which the mill uses power. Tube mills typify the grinding mills most generally used in cement plants, though other types are in use. Tube mills have been widely criticized as being extremely inefficient, and this feeling regarding them has led to many attempts to design more efficient grinding equipment. Other types may be an improvement over tube mills, but the improvement has certainly not been revolutionary, at least as applied to clinker grinding. The very fact that there is doubt regarding the relative efficacy of various types of mills is an indication that an adequate basis for an analysis of performance is lacking.

The development of methods of analyzing mill performance has been hampered by the lack of a suitable method for measuring the work actually done in pulverizing. There has been no acceptable standard to which mill performance might be compared. As a consequence, it was not known whether the margin of possible improvement in pulverizing operations was large or small. Even direct comparison of different types of mills was seldom possible because most plants had only one type of mill for each type of service. Comparisons between plants were difficult because of differences in the grinding characteristics of various clinkers.

Some recent developments complete a chain of circumstances that place the cement industry in a particularly fortunate position for the study of its clinker-pulverizing operations. Modern investigators of grinding phenomena have generally agreed that the best measure of mill performance is the production of new surface. For most materials this measure of performance is largely theoretical and has a rather remote connection with the practical aims of the grinding operation. In clinker grinding, on the other hand, surface area is intimately connected with the properties conferred on the cement by grinding. Moreover, the determination of surface area is rapidly coming into routine use as a test of fineness. Thus, the test which has been difficult to make and which has only theoretical value for most materials, is easy, practical, and direct when applied to clinker grinding. Clinker is almost unique in this respect, among all materials that are subjected to grinding.

Some recent developments complete a chain of circumstances that place the cement industry in a particularly fortunate position for the study of its clinker-pulverizing operations. Modern investigators of grinding phenomena have generally agreed that the best measure of mill performance is the production of new surface. For most materials this measure of performance is largely theoretical and has a rather remote connection with the practical aims of the grinding operation. In clinker grinding, on the other hand, surface area is intimately connected with the properties conferred on the cement by grinding. Moreover, the determination of surface area is rapidly coming into routine use as a test of fineness. Thus, the test which has been difficult to make and which has only theoretical value for most materials, is easy, practical, and direct when applied to clinker grinding. Clinker is almost unique in this respect, among all materials that are subjected to grinding.

While actual mill accomplishment is now readily subjected to measurement, a complete rating of a mill demands the establishment of a standard of perfect accomplishment. The ratio of actual to perfect accomplishment is the proper basis for estimating efficiency of any process. The establishment of such a standard necessitates the development of a test of the grinding properties of a clinker which reveals the amount of energy needed to produce a certain amount of new surface. This paper describes a new grindability test, and shows how it may be applied to a study of the performance of laboratory and commercial grinding mills.

Impact Grindability Test

Many grindability tests have been proposed and used. The new test described here has some distinct advantages which warrant its presentation. The essentials of any grindability test are a means of pulverizing the sample under some sort of controlled conditions and a means of measuring the amount of pulverizing accomplished. Many grindability testers are simply batch mills in which energy is continuously applied to a sample of material. At best, such devices give only relative information, since even if the energy input is known, there is no way of knowing how much is applied to pulverizing the sample. They therefore require the use of some material as a standard of comparison. Another disadvantage of devices of this type is their general tendency to change in efficiency during a test. The extent of the change may vary from sample to sample, or even between duplicate tests on the same sample.

The experimental difficulties in the determination of the surface of fine powders have frequently led to the use of highly inaccurate methods of estimating surface from the sieve analysis. Difficult or unreliable surface-area measurements have been a serious obstacle to the development of a really satisfactory grindability test.

Some investigations by Gross and Zimmerley resulted in the development of a method which was not subject to the objections suggested above. Their apparatus was an impact crushing device, in which the impact was supplied by a freely falling weight. This device was practically frictionless and provided an accurate measure of the energy applied to the sample. The surface of the product was measured by a rate of solution method which apparently was fairly accurate and reliable— certainly much more so than calculations based on sieve analyses.

This method of surface measurement required expert manipulation and was rather slow. It is doubtful whether it could be used successfully on cement clinker. More recently, Wagner has developed a method of surface measurement that is especially adapted to cement and is rapid and reliable. The Conservation Bureau of the Portland Cement Association (unpublished reports) has conducted researches that establish the propriety of using an impact crushing method as a grindability test, and others that provide some necessary correlations of surface measurements of fine and coarse particles.

The grindability test developed by the author is a combination of the pulverizing method of Gross and Zimmerley and the surface-measurement method of Wagner. The pulverizing apparatus and method have required some modification to fit them to the specific needs of a clinker-grindability test. The test gives the grindability of the clinker directly in terms of surface produced by a unit of energy applied under conditions about as favorable as can be imagined.

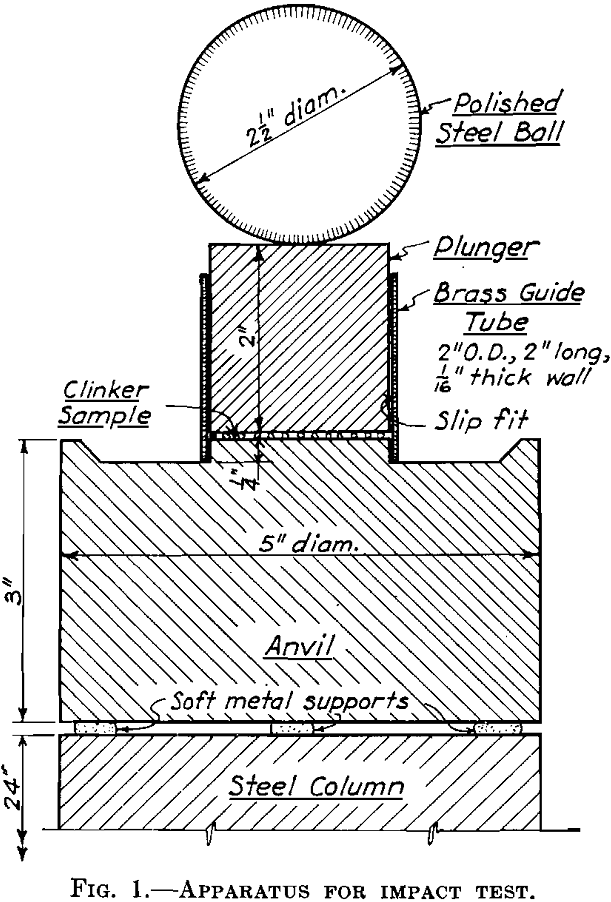

The crushing apparatus for the impact grindability test is sketched in Fig. 1. It consists of an anvil, a plunger, and a guide tube. The guide tube is a 2-in. length of 2-in. brass tubing. The anvil and plunger are hardened tool steel (Ryerson VD). The anvil is machined flat on the lower surface and to the shape shown on the upper surface. The center boss and the peripheral ring project ¼ in. above the annular depression between them. The boss is machined to a diameter that fits closely but not tightly inside the guide tube. The plunger is machined to the same diameter as the boss on the anvil, and to a length of 2 in. The entire surface of the plunger and the surface of the boss were machined smooth and polished with fine emery after hardening. The anvil is supported on a 2-ft. length of 5-in. diameter mild steel bar set upright in a concrete base. A set of three small rods of soft metal is placed between the anvil and the column. Impact is supplied to the plunger by a 2½-in. polished steel ball of the sort used in ball bearings. The ball release is an electromagnet provided with a steel ring which centers the ball at the same place for successive drops. The magnet is supported in a frame that can be set to allow the ball to drop various distances and is placed so that the ball strikes the center of the plunger when the anvil is set with its sides flush with the sides of the column.

In the test procedure that has been adopted as the standard, a 1-gram portion of 20 to 28-mesh crushed clinker is subjected to the impact delivered by a 24-in. fall of the ball. The clinker is spread uniformly over the surface of the anvil with the brass guide in position to serve as a retaining ring. This quantity of clinker makes a layer one particle thick, covering more than half the crushing surface of the anvil. The plunger is inserted in the guide and rotated slightly without pressure. The anvil is placed on the column, the ball is placed in the magnet, and released by switching off the current. The crushed material is washed into a test tube with kerosene from the turbidimeter stock. The crushing operation is repeated until four portions have been treated. Some clinkers yield too much or too little fine material from four blows for best results in the turbidimeter. If this situation arises, the duplicate test is made with three or five blows, or in rare cases with six blows. The entire accumu-

lated product is tested in a Wagner turbidimeter in the manner prescribed for tests of cement in that apparatus.

Reasonably close adherence to the prescribed routine is needed to obtain results in close agreement. The standard procedure was adopted after extensive experimentation, in which test conditions were systematically varied. The results of these studies, which are of value to the student or prospective user of the method, are briefly summarized in the following paragraphs.

Preparation of Sample.—The test is made on a sample of approximately uniform particle size, usually 20 to 28 mesh, cut from a crushed sample by rough sieving. In this condition, the sample sometimes contains enough dust, mostly finer than 10 microns, to effect a 10 per cent error in results. It is therefore washed with kerosene, rinsed with naphtha and dried by heating. Oversize and undersize material are removed by another sieving. The rotating brush used for dispersing cement in the turbidimeter test is a convenient aid in washing the sample.

Particle Size of Material Tested.—It is desirable to confine tests by this method to clinker samples of nearly uniform particle size. It is not strictly necessary that the test be made on 20 to 28-mesh clinker. Clinker is sufficiently fine grained to warrant the belief that particles of varying size are not inherently different in grindability. In developing this test considerable attention was given to a study of the effect of particle size on the resistance to grinding. So far as reliable experimental work has gone, no great difference has been found in the grindability of different sized particles.

Size of Portion Tested.—The quantity of clinker that can be crushed by a given blow is approximately proportional to the particle size of the clinker. A test on exactly the amount that can be crushed would obviate any inaccuracy due to variable resistance to crushing among the different particles, but would involve tedious experimentation on each clinker. Experiments with varying amounts of clinker show some variation in results, with increasing yields of surface as the quantity treated is increased. It appears that the use of an unduly small quantity is accompanied by increased energy losses, which are not completely measured. The use of quantities greatly in excess of the amount that can be crushed seems to cause a noticeable amount of localized breaking of edges and corners as distinguished from general shattering of the particles. With the general run of clinkers, about one gram of 20 to 28-mesh clinker can be crushed by one blow of the intensity regularly used in the test. The results are in good agreement with those obtained when the amount is selected so as to leave only a trace of uncrushed residue. A 1-gram sample is therefore used in tests of the 20 to 28-mesh fraction. For other fractions or for blows of different intensity the quantity used is varied in proportion to the particle size or the impact energy of the individual blow. Fractions finer than 35 mesh are tested in 0.5-gram portions.

Intensity of Blow.—The selection of the amount of energy to be applied at each blow is a matter of expediency. Inasmuch as the Wagner turbidimeter is used in the test, the amount of fine material in the accumulated product must be such as to give a suitable range of readings on that instrument. This amount of fine material requires the use of a certain amount of energy for its production. This energy can be applied in the form of many light blows or a few heavy ones. Since each blow, whether light or heavy, requires the same manipulation of apparatus and sample, a few heavy blows are used because of the saving of time. A limiting factor is the increase in energy losses and in the inaccuracy of measuring them as the energy of the individual blow is increased. For the apparatus described, a 24-in. drop of a 2½-in. ball is a generally satisfactory procedure for tests of fractions coarser than about 35 mesh.

General Technique of Crushing Operation.—The test is made by applying a single blow to each of several portions of dry clinker. In developing the apparatus comparative tests were run on dry clinker and clinker that had been moistened with kerosene prior to crushing. Manipulations were much easier with dry clinker and there was a tendency toward lower surface production with the moistened clinker. The application of repeated blows to a single portion would be desirable from the standpoint of lessened manipulation. This method was investigated and abandoned because of the tendency for the later blows to consolidate the product into hard flakes. As a result the surface-area measurements are less reliable, the energy losses are greater and their measurement is more difficult.

The prevention of dust losses is of considerable importance because even very small losses of fine material are enough to affect turbidimeter readings. The plunger is removed carefully to avoid a rush of air into the space vacated by the plunger. The material is moistened with kerosene and washed into a test tube, and the anvil is scrubbed with a “policeman” after each blow. The plunger and guide are washed and scrubbed after the final blow. The use of excessive quantities of kerosene is to be avoided, so that the entire product can be washed into two test tubes. If more than two tubes are filled, it may be difficult to get all of the sample into the turbidimeter tank.

Calculation of Surface.—The surface area of the material finer than 60 microns in the product is measured by the turbidimeter. The surface of the portion coarser than 60 microns may be computed from a sieve analysis. For this purpose the turbidimeter suspension is decanted through a 325-mesh sieve, and the residue is washed with naphtha, dried and sieved with No. 28, 48, 100 and 200 sieves.

Tests on a large number of clinkers indicate that no serious error is introduced if the total surface is computed by applying a constant factor to the surface indicated by the turbidimeter. The ratio of the surface of the 0 to 60-micron portion to the total new surface varied from 0.82 to 0.86 in tests on more than 20 clinkers. In the method now followed, the surface of the 0 to 60-micron portion is divided by 0.84 to get a value for total new surface. It appears probable that this simplified method introduces no greater uncertainty than exists with very careful hand-sieving and is superior to results that would be obtained with less careful sieving. Omission of the sieve test permits a substantial saving in time.

In order to calculate the surface of the 0 to 60-micron portion, the “transmittancy constant” of the clinker must be known. In tests of cements this constant is computed from the turbidimeter data and the 325-mesh fineness of the cement. The small amount of fine material in the product of the impact test makes it impossible to obtain a sufficiently accurate 325-mesh sieve determination. Where the test is being made in connection with mill tests, the constant derived on the mill product may be used for the impact test. Where no finely ground product is made, the constant can be evaluated by a turbidimeter test on the fine product obtained by dry-sieving some of the crushed clinker through a 325-mesh sieve, and resieving to insure the absence of coarse particles.

Computation of Energy Applied to Clinker.—The total energy input in the test is the product of the weight of the ball, the distance it falls, and the number of blows. If the anvil is placed directly on the column, the ball bounces on striking the plunger. This bounce represents a loss of energy that is difficult to estimate quantitatively. All or part of this loss may be recovered if the bounce is vertical and the ball returns to the plunger, but sometimes the ball bounces at an angle. The bounce is eliminated if the anvil is allowed to yield slightly at the instant of impact. This slight mobility of the anvil is provided by placing three rods of soft metal between the base and the anvil. The deformation of the rods provides a means of estimating the energy lost in movement of the anvil. This method was used by Gross and Zimmerley, but the heavier anvil in the apparatus described above necessitates the use of a different method of calibration and of softer metal than they used.

The rods used with the apparatus are prepared from 1/8-in. solder wire, cut in 0.4-in. lengths and slightly flattened to a thickness of 0.10 to 0.11 in. before use. The procedure for calibrating the rods to obtain their energy-deformation relations is as follows: Three previously flattened rods are placed below the anvil and three or more are placed on the anvil in the position normally occupied by the clinker being crushed. The rods are selected for uniform thickness, are uniformly spaced, and the anvil is placed so as to receive a well centered blow. The thickness of each rod is measured with a micrometer before the first blow and after each of several successive blows. In deriving the energy-deformation relations, it is assumed that the entire impact energy of the ball is divided between the two sets of rods. When the construction of the apparatus and the relative weights of the support column and the anvil are considered, this seems a reasonable assumption. A graphic method is the simplest means of determining the distribution of the total energy between the upper and the lower sets, since deformation is not a linear function of the energy applied. The average total deformations of the upper rods are plotted against the number of blows. The deformation of the lower set after several blows will approximate that of the upper set after the first blow, and the distribution of the energy between the two sets can be read fairly accurately from the curve. From this distribution, the energy-deformation relations of the rods are calculated. The number of rods in each set must be considered in making the calculations.

With the apparatus described, 85 per cent of the energy was absorbed by the upper set of rods in the calibration test. In a test on clinker, the distribution of energy between the clinker and the rods supporting the anvil may differ from the distribution in the calibration test. In tests of clinker, the energy equivalent of the deformation of the support rods is subtracted from the total energy to obtain the amount of energy applied to the clinker.

The conditions of test affect the magnitude of the energy correction to a considerable degree. The size of the correction increases with increasing intensity of the blow, with decreasing quantity of material and with decreasing particle size. In tests of very fine fractions with a heavy blow, the energy correction becomes large, sometimes exceeding 50 per cent. Tests of the 20 to 28-mesh fraction with blows of approximately 20, 40 and 60 kg-cm. give reasonably consistent results, though the energy corrections vary. Similar results are obtained with light-blow tests on finer fractions, but with a heavy blow even the large indicated correction appears inadequate. There may be some elastic recovery of the solder rods, which becomes noticeable only when deformation is great and rapid. The distance traveled by the plunger in absorbing the kinetic energy of the ball and transmitting it to the clinker varies with the particle size and quantity of sample. The relations between this distance and the time of impact are the probable cause of differences in the amount of the energy correction.

The elasticity of the various parts of the apparatus probably has some bearing on the reliability of the measurements and calibration. As an example, different results were obtained with two different balls of the same weight. A ball described by the manufacturer as high-carbon chrome-alloy steel was used for most of the earlier tests, and was later replaced by a polished steel ball of the type used in ball bearings. The surface production with the first ball was consistently about 12 per cent lower than that with the one used later. A simple bounce test indicated that there was a difference in the elastic properties of the two balls. It thus appears quite possible that this method of estimating energy losses is not highly accurate in an absolute sense. In a relative sense, its precision is such that the difference in net energy in duplicate tests seldom exceeds 3 per cent and averages less than 1.5 per cent.

This calibration procedure is somewhat tedious and even the measurement of the rods before and after the individual test adds appreciably to the time required for manipulation and calculation. In the course of experimentation on a number of clinkers of varying crushing properties, it was observed that the magnitude of the energy correction was practically constant for constant conditions of weight of portion, particle size of clinker, and intensity of blow. As a result of this observation the present method is to apply a fixed correction of 18 per cent. On the whole, it seems probable that an average correction represents the true situation more accurately than an individual reading.

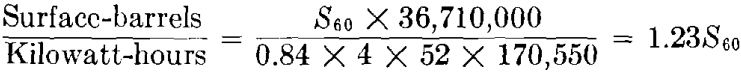

Calculation of Surface Production per Unit Energy.—The impact test gives an experimentally determined value for surface production per unit of energy input. This value can be variously expressed, but the most usable terms are those which can conveniently be applied to the analysis of mill performance. The unit of production in the cement industry is the barrel of 376 lb. The unit of specific surface is square centimeters per gram. In order to avoid unwieldy values, the surface production for mills is calculated in surface-barrels per kilowatt-hour, obtained by multiplying the increase in specific surface by the output and dividing the product by the mill power. The grindability of clinker is expressed in the same terms. In the apparatus used in these tests the total energy of the blow was 63.4 kg-cm., equivalent to 0.82 x 63.4 = 52.0 kg-cm. net energy. If the surface indicated by the turbidimeter test is designated as S60, the total surface is S60 ÷ 0.84. One kilowatt-hour is equivalent to 36,710,000 kg-cm., and one surface-barrel is equivalent to 453.6 x 376 = 170,550 sq. cm. The grindability value for a four-blow test is therefore:

Accuracy and Precision of Grindability Test.—Experimental errors in the grindability test may occur in either the crushing operation and manipulation or in the measurement of the surface. Experience indicates that duplicate tests on different days should check within 3 per cent for acceptance. The absolute accuracy of the method is dependent on the interpretation rather than on the experimental precision. The systematic errors of surface measurement cancel out if the grindability test is used for the estimation of mill efficiency. The most serious source of doubt is the method of determining the energy actually applied to the clinker. In the absence of adequate theoretical standards, the practical solution is to arrange the crushing operation so as to make highly effective use of the energy, to allow for such energy losses as can be measured, and to accept the results as a working relation between energy used and surface produced. The conditions under which the test is made have been carefully selected so as to balance favorable and unfavorable factors in such a way that the impact test represents what may reasonably be considered as perfect mill performance.

Grindability Test in Analysis of Mill Performance

In conventional mills the production of surface is less efficient than in the impact test. The basic cause of this inefficiency is doubtless the inability of the grinding surfaces to apply their energy effectively to the particles. Several factors may contribute to this ineffectiveness. The grindability test gives a basis for estimating the degree of effectiveness in the application of energy to the particles being pulverized, by providing means for computing the ideal rate of surface production for a given power input to the mill. The units used in reporting grindability are such that the ratio of the surface-barrels per kilowatt-hour produced in the mill to the grindability value for the clinker is the efficiency of the mill.

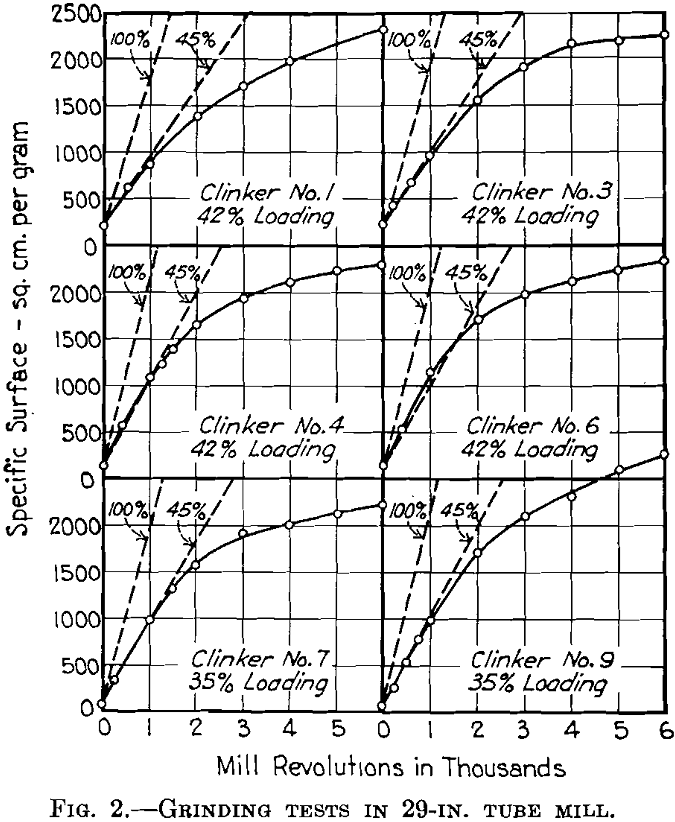

Laboratory Mill Tests.—In order to get information on the consistency between grindability values and the grinding rate in a conventional mill, it was necessary to grind several clinkers of different grindability in the same mill. The tests were made in a batch tube mill, 29 in. in diameter and 40 in. long. This mill was large enough to permit reasonably reliable measurements of the power input. The net power delivered to the mill was used in the calculations, by making suitable allowances for dead-load losses in the motor and drive. In these batch mill tests, the mill contents were sampled at frequent intervals for surface-area determinations. The results of tests on six clinkers are shown in Fig. 2. In each diagram the solid line is obtained by plotting specific surface against mill revolutions. The positions of the straight dotted lines are computed from the grindability test. The line marked 100 per cent shows the change in surface that would result if the mill were as effective as the impact apparatus in translating mechanical energy into surface production. The line marked 45 per cent shows the change in surface for mill operation 45 per cent as effective as the impact test. The 45 per cent line approximates the actual grinding rate in the earlier stages, indicating a mill efficiency in the neighborhood of 45 per cent.

The consistency with which the impact test indicates the initial tube-mill grinding rate is evidence of the value and essential reliability of the impact test. For these constant mill conditions, the degree of concordance in the instances cited is about as good as the accuracy of the turbidimeter tests and the power readings. Occasional instances have been noted of less exact concordance but there are not enough of them to cast serious doubt on the general value of the impact test. It appears that the grinding resistance of the clinker has no effect on the efficiency of the mill during the earlier stages. As the material in the mill becomes finer, mill efficiency decreases and the rate of surface production drops below the initial rate. This first decrease may be due to the reduction of maximum particle size below the limits of sizes effectively ground by the ball charge. The greater decreases in efficiency at high fineness appear to be caused by ball coating. Clinkers differ in their tendency to coat the balls. This difference may be a specific property of each clinker or may be due to unrecognized differences in test conditions.

The changing rate of surface production is attributed to changing efficiency of the mill. During the earlier stages of the tests in the tube mill, the mill efficiency remains very nearly constant for a time and is very nearly the same with different clinkers. In this part of the tube-mill test, the impact test data are consistent with the tube-mill data. In the later, less efficient stages, no such consistency exists because the reasons for decreased efficiency and the extent of the decrease are varied, and are not necessarily related to grindability.

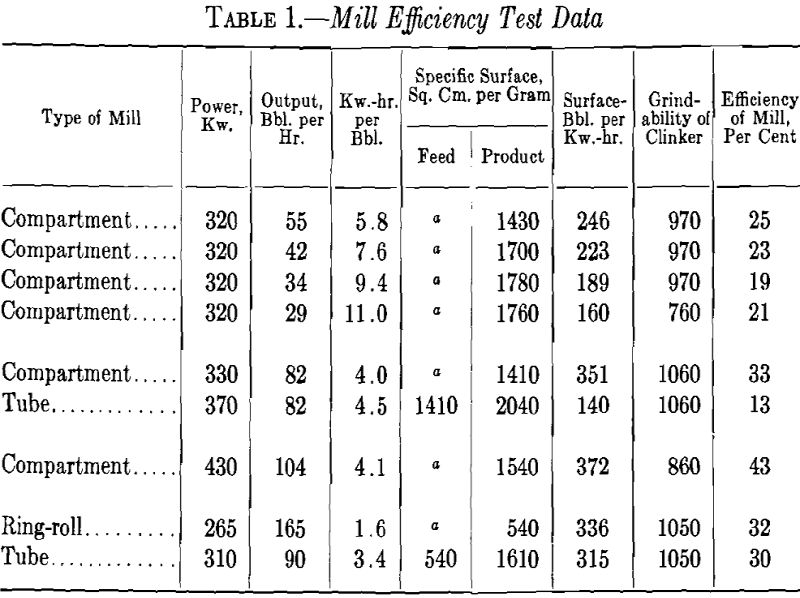

Commercial Mill Tests.—This method of analysis has been applied to several commercial mills of various types. The design of mills and the commercial requirements imposed on the product limit the test conditions to a narrower range than that covered by the batch mill tests discussed above. At outputs that yield a product coarser than about 1400 specific surface, most of the mills tested operated at an efficiency between 25 and 40 per cent. These values are much higher than have been estimated on theoretical grounds by various investigators. It may reasonably be doubted that the theoretical grounds on which these estimates of extremely low efficiency are based are applicable at all to the pulverizing operation. In view of some of the impressions of extreme inefficiency of pulverizers, the indications of these tests are rather reassuring. The reasons for the spread in efficiency among various mills are not clearly recognized. The margin between 25 and 40 per cent efficiency is a substantial one, and worth the attention of the designer and operator.

Of necessity, the power figures in the commercial mill tests were for electrical power supplied to the mill motor. Dead load losses, in the motor, the drive and the mill bearings, will account for at least 20 per cent of this total. A smaller amount is used in movement of clinker within the mill, a power use that yields little return because the impacts resulting from it are too light to shatter the particles. The major source of power loss is probably in the form of ineffective contact between the grinding surfaces and the material being pulverized.

In very fine grinding in tube mills, the balls near the discharge end become coated with reconsolidated fine material, the effectiveness of contact is decreased and mill efficiency becomes lower than in coarse grinding. Proper closed-circuit operation can overcome much or all of this difficulty. The methods of analysis used in these tests suggest a means of judging the efficacy of closed-circuit operation by comparing efficiency at high and low output rates.

Some representative test data are recorded in Table 1. The tests indicate that there is room for substantial improvement in the design and operation of clinker-grinding equipment. By setting a probable theoretical limit of performance, the grindability test is helpful in estimating the distribution of power losses and in analyzing the possibilities for improvement.

General Discussion

As a grindability test for Portland cement clinker, the impact test described in this paper has some definite advantages over other methods that have been used. These advantages lie in the combination of an improved measurement of surface production with a measurement of the energy actually applied to the clinker.

The recent development of the Wagner turbidimeter has made the measurement of surface area rapid and comparatively accurate. This instrument is probably not capable of an extremely high degree of absolute accuracy. The experimental evaluation of the constant relating light absorption to surface is subject to some error. Irregularities of particle shape and translucence of light colored or extremely minute particles introduce inaccuracies in the conventional treatment of the observed data. However, the Wagner instrument provides a measure of surface area that is, for all practical purposes, a close approach to the actual surface area. Moreover, and of particular importance, the systematic errors in surface measurement are of the same sort in both grindability test and mill tests on the same clinker. Thus, from the standpoint of surface measurement alone, greater inconsistencies would be expected among grindability tests on various clinkers than between grindability and mill tests on the same clinker.

The chief virtue of using the impact of a falling ball for the pulverizing operation is that this method permits the relation of surface production directly to energy input. A single impact is applied to each portion of clinker. This feature insures greater constancy in test conditions than is possible in other types of grindability-test devices. In consequence, the results of the impact test are a measure of the pulverizing properties of the clinker, divorced as completely as possible from questions of pulverizer efficiency. There is no theoretical proof that the impact test provides an absolutely complete utilization of energy in the form of pulverizing. However, general principles of mechanics indicate that a close approach to this ideal condition is obtained in the test, and extensive experimentation has apparently eliminated the most serious departures from this condition. The test makes no attempt to do more than measure directly the amount of surface that is produced by applying a given amount of energy. Other effects, such as the production of heat, are not measured. The test measures only the “pulverizing component” of the energy used.

In the course of the development of the impact test for clinker, some observations were made which contributed materially to a better understanding of the mechanism of the pulverizing process. While the tests were confined to clinker, the generalizations based on them probably apply to other close-grained, rigid materials. As a result of these observations, it was concluded that much of the pulverizing action that takes place in conventional mills consists of shattering the coarser particles by impact. When a particle is subjected to an impact of sufficient intensity, it shatters into many pieces, ranging in size from less than one micron up to a top size that depends on the intensity of the blow. Apparently much of the grinding action in a conventional mill is accomplished by a process of this sort. A blow too light to shatter the particle completely, or a glancing blow, may cause local shattering at the point of contact, or a chipping of corners and edges. Some action of this sort seems to take place during the entire grinding process, becoming more pronounced as the particle size is reduced. A small amount of grinding may occur by a process of attrition or abrasion in which the particles are rubbed by the grinding surface. This is similar to chipping of corners except that the product is finer. Whether reduction of particle size takes place by complete shattering, by localized shattering, or by simple breaking or chipping, the process consists of shearing the particle. For each unit of area subjected to shear, two units of area of new surface are formed. This is the basis of the generally accepted Rittinger law, that surface production is the measure of work done in pulverizing.

The grading of the product of impact is remarkably constant for varying conditions of crushing the same clinker. There are differences in the grading of the products of different clinkers, particularly in the grading below 60 microns as calculated from the turbidimeter test. The specific surface of the 0 to 60-micron part of the impact product ranges roughly from 1000 to 1500 for different clinkers, equivalent to an average particle size ranging approximately from 20 to 12 microns. The product of a conventional pulverizing operation is this impact product, augmented by the extremely fine material made by chipping of edges and localized shattering.

The impact test thus crushes the clinker by a process closely akin to that of the ordinary pulverizing mill. Much of the product of pulverizing in conventional mills is the result of successive shatterings, and all of the new surface results from shearing of the particles. The impact test, therefore, seems a proper and logical basis for establishing standards of performance of conventional pulverizers.

The impact test described here has been developed specifically for Portland cement clinker. The properties of cement are more intimately related to surface area than to sieve fineness. The surface-area basis of analyzing clinker-mill performance is therefore proper, on practical as well as theoretical grounds. Most other materials are pulverized for the primary purpose of reducing all the material to particles smaller than a certain critical or specified size, and surface area is of only secondary concern. A mill grinding such a material might be operating efficiently by the surface-production analysis, and yet be producing much of the new surface from material already fine enough, or by processes other than shattering of the oversize pieces. Judged by the purpose of the operation, this kind of grinding is inefficient. The turbidimeter could probably be adapted to other materials than clinker. If so, the impact test would facilitate the analysis of mill performance on the surface-production basis and might find some application as a means of estimating the amount of overgrinding of material below the critical size.

As applied to clinker, the impact grindability test has several useful functions. It is useful in the study of the effects of various factors of mill design and operation. It facilitates comparative tests of different mills even when operating on clinkers of diverse grinding characteristics. It gives some idea of the margin of improvement theoretically attainable. In addition to these items, helpful in the analysis of mill performance, the test is the fastest and simplest method available for studying the effect of various treatments of clinker on its grindability. The speed, simplicity and apparent reliability of the impact grindability test recommend it as a useful device for improving the definiteness and precision of mill testing.