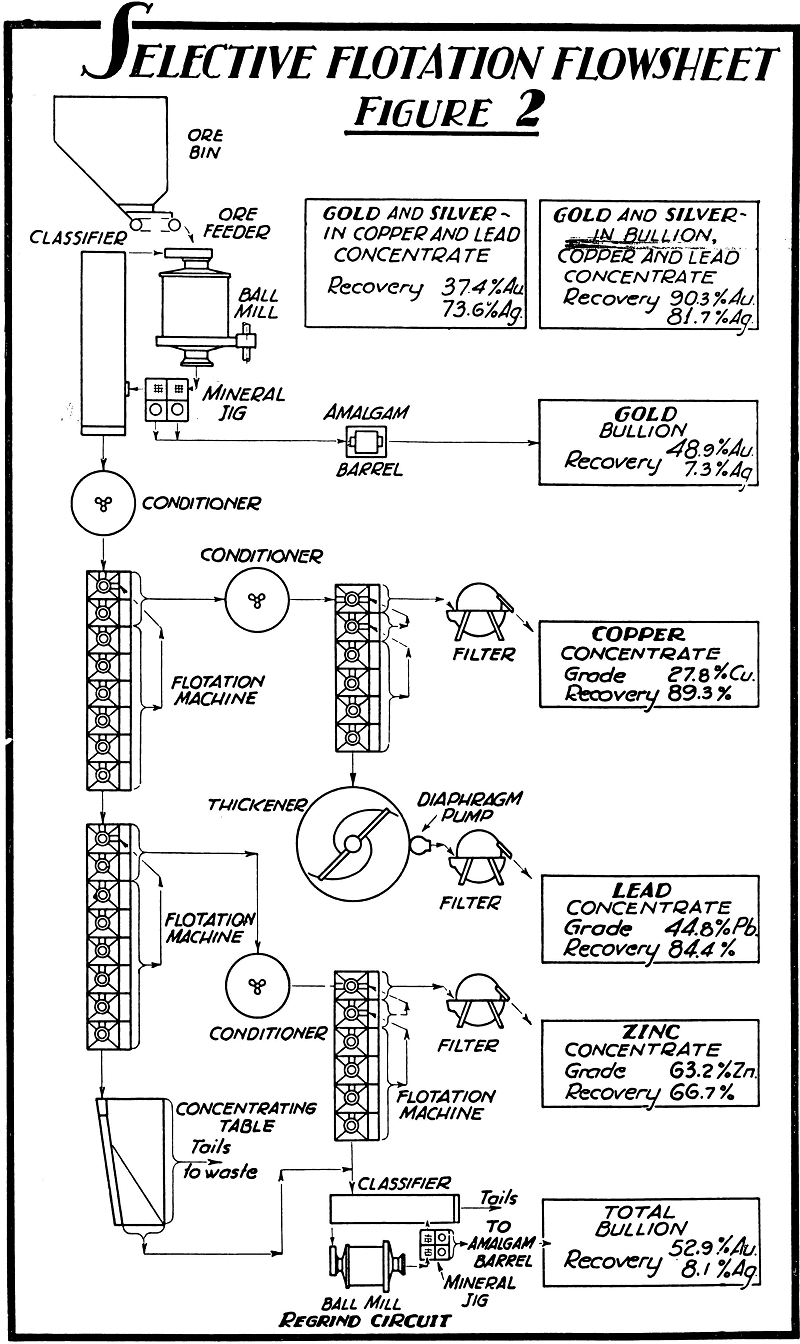

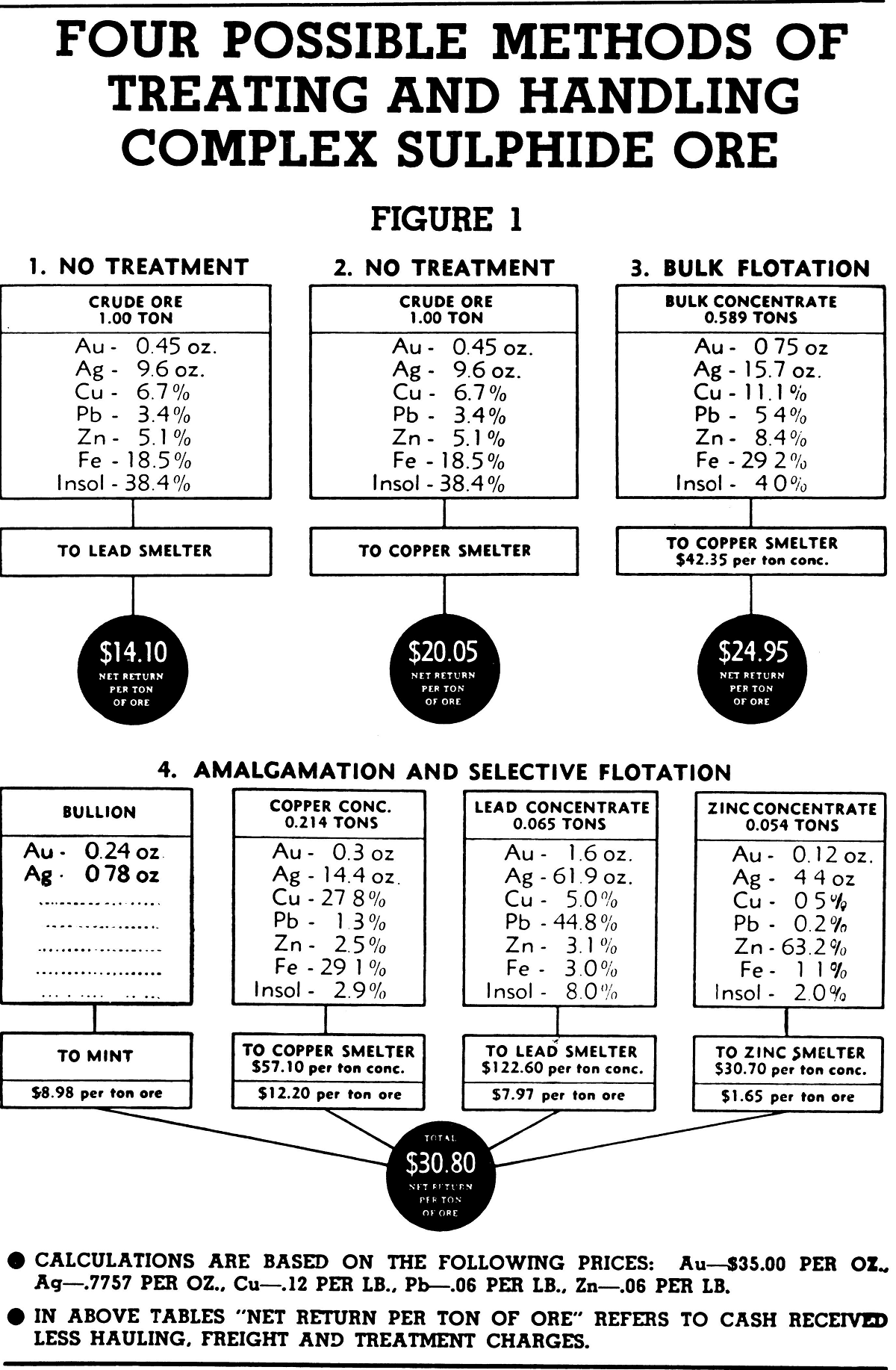

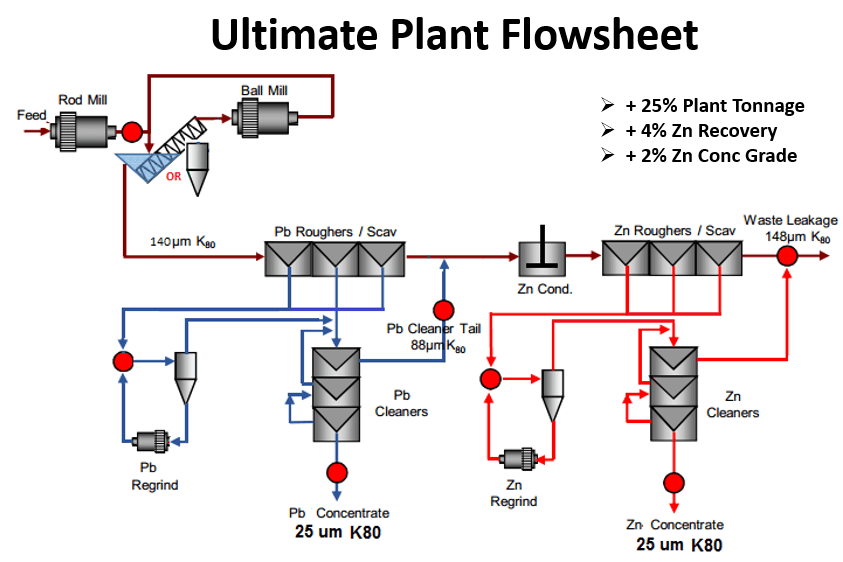

A successful search for and development of a new mineral deposit rests not only in its discovery but also in economical processing of the ore. Via the Science of its engineering, Mineral Processing and Extractive Metallurgy allows the evaluation of metal recovery Methods laid-out or expressed as a process flowsheet.

The challenge of discovery and development, the processing and profit from mineral resources have resulted in many different process flowsheets. There has been a constant advance in mineral technology for hundreds of years. The process flow we consider highly successful today may be replaced tomorrow by new developments, improvements in equipment or changes in the ore being treated. In the progress of mineral processing “There is no substitute for experience”.

Basic to every flow-diagram is the understanding, the thinking and analysis that must be made of the problem. An idea borrowed here, an improvement added there and the determination to “find the better way” will strengthen profits and advance the industry.

For years Mining Equipment Companies have contributed to the progress of the mineral processing industry. Extensive research in Ore Testing and Process Development as well as intimate understanding of treatment methods used by successful plants all over the world, has provided a background of most valuable experience. Not to share this experience with others would be inconsistent with our policy of distributing technical information of value to Engineers. For, as a service organization, we are dedicated to the improvement and advancement of the mineral processing industry.

This website and its flowsheets includes selected items on the treatment of a wide range of minerals. It is a worthwhile reference volume for all who are interested in mineral processing. The flowsheets are all practical and represent the best practice in modern metallurgy and milling.

Batch Testing

This section is equipped to handle any type of batch test. The results, in many instances, provide all the necessary information upon which to base recommendations for a commercial plant. Another important function of batch testing is to determine the advisability of carrying out a full scale pilot plant test.

The data supplied by the testing in this section includes:

- Grindability of ores to determine point of mineral liberation and sizes of grinding mills.

- Agitation time and pulp densities to determine sizes of agitators and conditioners.

- Flotation data including general amenability to flotation treatment, concentrate grades, recovery, optimum flotation time, and densities for determining capacities and reagent combinations.

- Settling rates of pulps to determine sizes of thickeners.

- Filtering rates to determine filter sizes and types most advisable.

- Special amenability tests to determine the grade of concentrates and the recoveries by either the Denver Mineral Jig, the Denver Unit Cell, or both, in the ball-mill classifier circuit.

- Hydrometallurgical tests.

Continuous Testing

The pilot concentration plant is completely equipped with gravity and flotation units sufficient to provide for practically any flowsheet employing these methods of concentration. All equipment is set for continuous operation. Movable launders, pumps and flow pipes, permit extreme flexibility.

The conduct of ore tests in the batch laboratory and large-scale tests in the pilot plant conform as nearly as possible to the conditions which will exist in the proposed milling operation. Consideration is, of course, given to any factors beyond the control of the operators of the commercial milling plant, such as climatic conditions, elevation, etc. Water supply, as it is available to the commercial plant is duplicated as closely as possible.

This continuous, or pilot plant testing provides an intermediate step to further insure successful commercial milling.

Flowsheet Design

At the completion of the tests, a detailed report and recommendation are submitted, and mill flowsheets are recommended based on laboratory test results. These reports, analyzed and prepared by experienced metallurgists, are practical, complete and easy to understand. Even those who are unfamiliar with technical terms can clearly understand that the results of the tests, accurate test report and recommendations help long-range planning.

- Designing a Conveyor System

- Crushing & Screening Plant Design

- Crushing and Grinding Wet & Sticky Ore

- Two Stage Grinding Circuit

- Rod Mill and Ball Mill

- Flotation Machine

- Flotation Cell Impeller Types

- Agitators

- Fine VS Coarse Particle Flotation

- Flash Flotation

- Leaching Plant Design

- Electrolytic Refining

- Aluminium

- Barite

- Beryllium

- Calcite

- Chromite

- Coal

- Copper

- Copper-Pyrite

- Copper-Zinc

- Copper Leaching

- Diamond

- Feldspar

- Fluorspar

- Gold and Silver Leaching

- Sulphide Gold Ore Treatment

- Small Gold Processing Plant

- Gold Mining and Milling as a Business

- Small Scale Gold Mining Business Plan

- Gold Leaching

- Lead-Barite-Fluorspar

- Lead Carbonate (Cerussite) Ore Beneficiation Process

- Hematite Flotation

- Graphite Beneficiation Process

- Gold Placer Deposits

- Batch Cyanidation of Flotation Concentrate

- Silver Lead Zinc

- Galena-Sphalerite

- Manganese Ore Processing

- Oxide Lead Ore

- Lead – Zinc Sulfide

- Oxidized Lead-Zinc Ore

- Mercury

- Leaching Mercury Sulfide

- Lead Zinc Copper

- Scrap Metal Recycling Process and Equipment

- Mica Recovery from Scrap

- Portable Mineral Processing Plant

- Small Gold Leaching Circuit Design

- Tin Beneficiation Process

- Design Flotation Plant

- Molybdenum Ore Processing by Flotation

- Tungsten

- Titanium

- Sulphur Recovery Process

- Spodumene & Lithium

- Silica Sand

- Recycling Sand

- Pyrite Tailings

- Potash

- Phosphate

- Phosphate Flotation

- Perlite

- Pegmatite Minerals

- Non-Metallic Minerals

- Tungsten from Scheelite

- Tungsten-Gold from Wolframite

- Tungsten Metallurgy

- Uranium Processing

- Uranium Metallurgy

- Beneficiation of Iron Ore

- Heavy Media Separation Process

- Different Types of Flotation Cells

- Segregation Process of Mixed Sulphide Copper Ore

- LPF

- Copper LPF Leach Precipitation and Flotation Process

- Copper Flotation

- Antimony Processing by Flotation

- Electromagnetic Separation

- Uranium Ore Processing Methods

- Vanadium Extraction Process

- Tungsten Metallurgy

- Extracting Tungsten from Wolframite Gold Ore

- Extraction of Tungsten from Scheelite Ore

- Beneficiation Process of Kaolinite Clay

- Explain the Extraction of Tin Ore

- Talc Beneficiation Process

- Cement Rock Beneficiation Process

Selecting Equipment Sizes

In addition to the flowsheet and reports, equipment sizes required for your specified tonnage operation are submitted. These recommendations are followed by a detailed cost estimate of equipment required.

Mill Design

Experienced engineers can plan your mill layout to assure maximum operating efficiency and convenience. Or, they will gladly cooperate with your own staff or with your consulting engineers. Our responsibility begins even before we receive your order. We want your mill to be a success, so our field engineers and metallurgists will do everything possible to keep your mill operating most efficiently and will pass on to you new developments to improve your metallurgy.