Molybdenite Roasting with Sulfuric Acid Plant VS Looping Sulfide Oxidation (LSO) with Sulfuric Acid Plant

- Engineering Design

- Construction

- Training & Start-up

- Capital Cost Studies

- Feasibility Studies

- Operations & Maintenance

- Peer Reviews

- Modernization

- Capacity Expansion

- Patents and Papers

MoS2 Roasting Experience

- Fort Madison, IO, USA

- Sierrita, AR. USA

- Langeloth, PA. USA

- Washington, PA. USA

- Winslow, NJ, USA

- Eureka, Nevada, USA

- Rotterdam, Netherlands

- Trollhaettan, Sweden

- Le Giffre, France

- Spigno Montferrato, Italy

MoS2 Roasting Experience

- Mejillones, Chile

- Chuquicamata, Chile

- Huaxian, Shaanxi, China

- Louyang, Henan, China

- Yeosu, South Korea

- Sorsk, Russia

- Chelyabinsk, Russia

- Yerevan, Armenia

- Stowmarket, UK

- Goslar, Germany

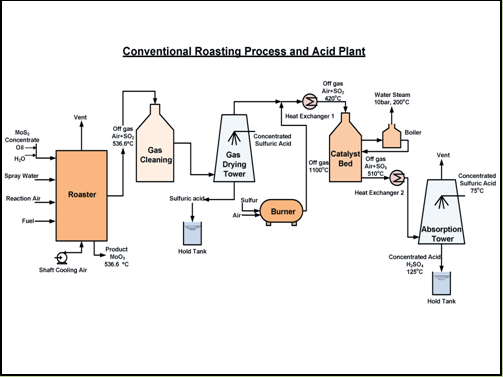

Current Multiple Hearth Roasting

Molybdenite MHR – Advantages

- Multiple Hearth Roasters are available reliable furnaces.

- Roasting reactions are slowed allowing for furnace temperature control.

- SO2 off-gas can be fed to recovery processes which also produce a salable by-product. (Sulfuric Acid)

- Existing equipment is utilized with non-exotic materials of construction.

Molybdenite MHR – Disadvantages

- Significant energy recovery is not possible.

- Reactions are slow and inefficient requiring large surface area roasting equipment size.

- Operating Labor and Operating conditions are less than ideal. (Cleaning of Arms, Teeth, Dropholes, Off-Gas Ductwork, etc.)

- Low concentration SO2 off-gas can be fed to the acid plant but generally need additional fuel or SOx for acid conversion.

- Low SO2 levels require large gas cleaning and acid plant volume capacities.

LSO Looping Sulfide Oxidation Development

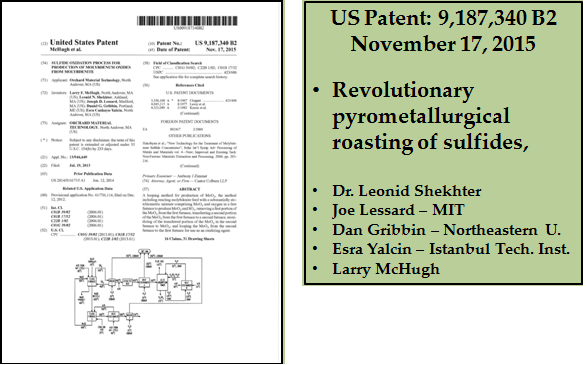

Mo Looping Sulfide Oxidation – Patent

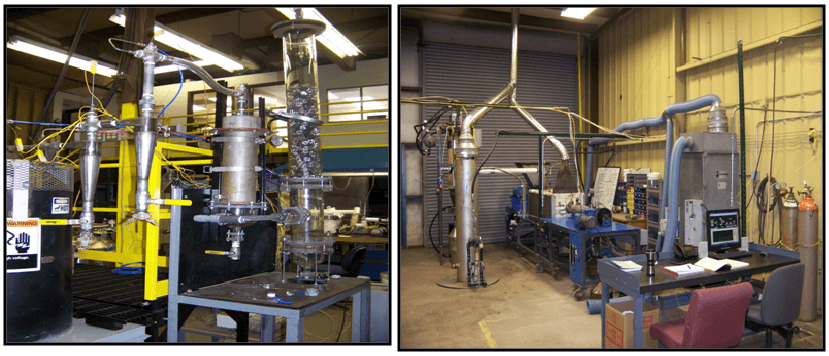

LSO Pilot Plant Tests

Molybdenite LSO Continuous Process Reactor Systems

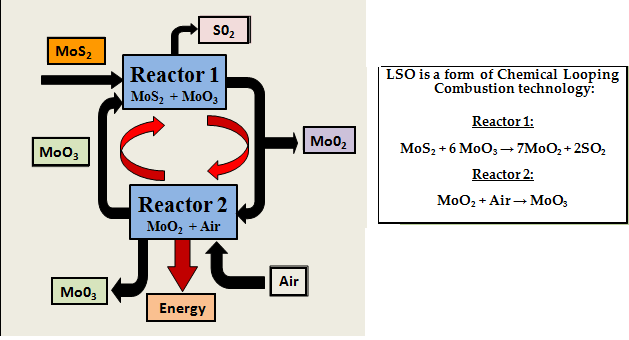

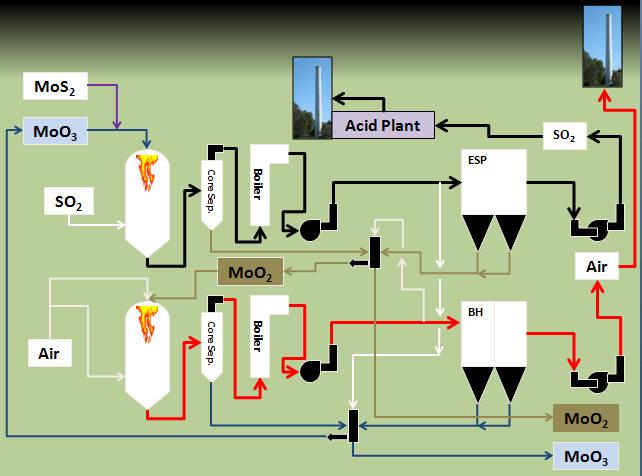

Looping Sulfide Oxidation – LSO

- The two-step “looping oxidation” process effectively removes sulfur while producing products of excellent purity in an energy generating and environmentally friendly manner.

Reactor 1: MoS2 + 6 MoO3 → 7MoO2 + 2SO2

Reactor 2: MoO2 + Air → MoO3 - OMT’s new patent greatly increases the energy generation potential of LSO.

Molybdenite LSO

Molybdenite LSO – Advantages

- Significant energy generation is economically attractive.

- Rich SO2 off-gas can be fed to efficient ancillary recovery processes which also produce energy.

- Reactions are fast and efficient allowing for reduced equipment size.

- Maintenance costs reduced and Operating Labor and Operating conditions are greatly improved.

- Commercially available equipment is utilized with non-exotic materials of construction.

- Efficient rhenium recovery is also possible.

- Both LSO reactors operate in an exothermic manner allowing for stable rapid reaction kinetics.

- SOx strength will exceed levels achievable by any other process. This will allow for smaller acid plant equipment or greatly increased efficiency of an existing acid plant.

- MoO2 can be produced which is a better product for alloy steel applications. MoO2 has a higher Mo content and is more stable in alloying practice improving recovery of Mo into the alloy steel.

- High solubility MoO3 and/or MoO2 can be produced in any desired ratio.

High Energy Looping Sulfide Oxidation

Molybdenite LSO Facility

NEXT – LSO Pyrometallurgy

- The ‘Looping Process’ can be utilized to generate energy and treat other large volume primary metals.

- To date positive results have also been demonstrated with:

- Mo, Co, Cu, Fe, CuFe – Sulfides

- Evaluations continuing with:

- Ni, Zn, Sn, Pb

- Energy generation from the Acid Plant is also large and quantified.

- SO2 condensation and recovery is also a viable SOx recovery method.