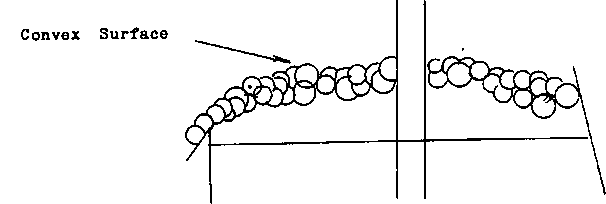

By now you are aware of the importance of the effect that the reagents have on single bubbles. Now we will begin to show you how the bubbles effect each other. In the cell the air, the reagents, the mineral and the impellor agitation all combine to create what is known as a FROTH COLUMN. The froth column is the distance between the top of the bubbles and the surface of the slurry that the mineral is floating on.

By now you are aware of the importance of the effect that the reagents have on single bubbles. Now we will begin to show you how the bubbles effect each other. In the cell the air, the reagents, the mineral and the impellor agitation all combine to create what is known as a FROTH COLUMN. The froth column is the distance between the top of the bubbles and the surface of the slurry that the mineral is floating on.

Consider stage collector addition to help control dosage.

This is a very important distance, if you took a cross section of the froth column the mineral would be distributed through it like this. At the very top of the bubbles the mineral would be of the very finest and the purest, as you descend into the froth the bubbles become smaller, the mineral particles that are on the surface of the bubbles.

This will cause the hold- that the collector has on the mineral to become less and less positive.

As new bubbles are formed they rise to the surface, the bubbles that hold very little mineralization will capture any collector molecules that has a poor surface contact with particles from the bubbles that are overloaded the particles of mineral which are held very lightly by the collector due to impurities or size will be displaced by any mineral that can make a positive attachment.

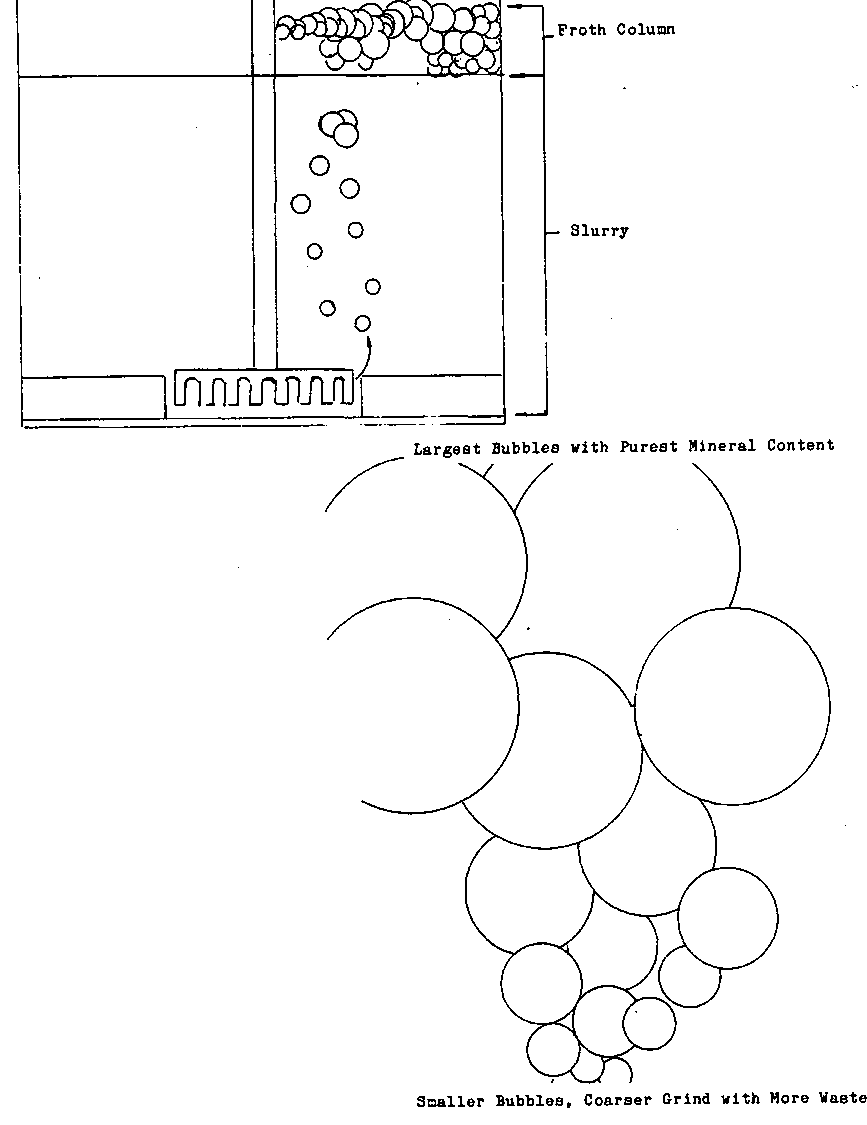

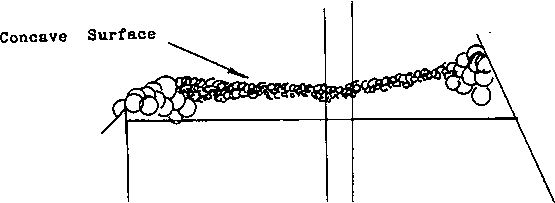

The deeper the froth column is, the cleaner the mineral will be that is on the surface. But if the froth is not removed fast enough it will become overloaded with mineral and begin to create problems for the rest of the circuit. A very good indicator that shows the load that the froth column is carrying is the size of the bubble and the shape of the surface of the column. The smaller the bubble and the flatter the surface of the froth the bigger the load is.

If the froth becomes CONCAVE instead of PLAT or CONVEX then it is over loaded and the mineral is beginning to sink instead of float.

Of course an overloaded float circuit will result from an imbalance of reagent addition as well as not moving the froth off of the cell fast enough.

Any time that you have an overloaded froth condition the OVERFLOW that is going over the side of the cell will slow down as the froth column begins to collapse under the weight of the mineral. The first corrective reaction is to raise the pulp level, slurry levels or add air to the cells to quickly increase the overflow.

Let’s start with froth bed or pulp level and air flow adjustments of your float cell as a first troubleshooting tool.