Ore Bucket Rail Cars are built of the strongest welded steel design and are built with the expectation that continuous service will be required of them.

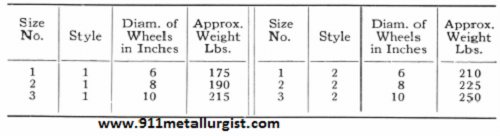

As shown in the accompanying illustrations, these cars are made in two styles, both of which are built as standard units for eighteen gauge track.

However, these ore bucket cars can be promptly manufactured to any individual specifications desired by the customer.

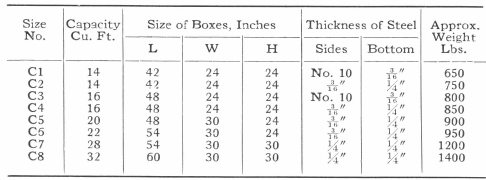

Style No. 2, which is equipped with bucket guard, is approximately 20% higher in price than Style No. 1. Specifications are given in the following table.

Car, Ore, (Rocker Dump)

Rocker Dump Ore Cars may be dumped to either side and easily returned to an upright position. A locking mechanism, located at the center of the car bottom and at the center of the frame, automatically stops the body when it attains an upright position.

The body is carried on heavy cast steel rockers and rocker stands, which are covered by a plate to prevent spilled material lodging on the rockers.

The body is made of heavy plate, properly braced and are welded, making a tight container with no doors or openings through which material can leak out onto the trackway.

Rocker Dump Ore Cars are made on order to meet operating conditions. These cars are popular in capacities ranging from 20 to 40 cu. ft. and for from 18″ to 24″ gauge mine track. Write for additional information.

Car, Ore, (Standard)

Standard Ore Car is made of the very best materials and is designed for the most severe service. Although it is regularly furnished with plain bearing wheels, roller bearings can be supplied whenever preferred. Ordinarily this car is built

for standard eighteen inch gauge track although special units can be quickly manufactured to the customer’s individual specifications wherever this is necessary.

The Standard Ore Car can be knocked down for airplane or muleback transportation to facilitate shipping to remote localities.

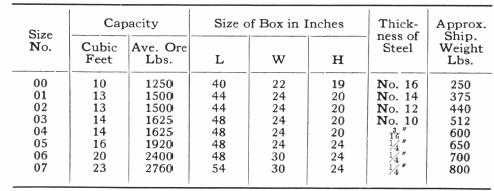

Car, Ore, (Standard Cage)

(Standard Cage) Ore Car body is of heavy plate steel and all forgings are of the best quality iron and steel. The truck frame is made of heavy channel iron with the body securely mounted. Hooks or slots are provided for securely holding the car to the

cage.

The standard gauge is 18″ but other sizes can be furnished. This car can be sectionalized for airplane or muleback transportation.

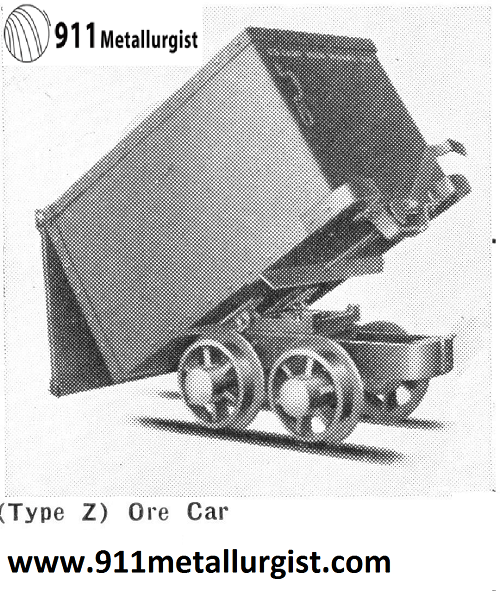

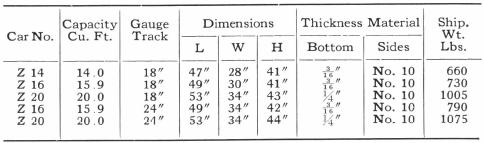

Car, Ore, (Type Z)

(Type Z) Ore Car will meet practically all conditions where cars of this style are required. The body is well braced and riveted and two angles are used to reinforce the bottom. Cars of twenty cubic foot capacity and larger are furnished with one reinforcing strap or band in the center of the body. Bumpers, used as handles when dumping, are located at the strongest part of the body. The door is well protected by a bracing strap at the bottom where the cars come together. The turntable is of cast iron with a grease lubricated machined groove, which takes most of the turning load off the king pin. The truck frame is in one

piece without riveted corners to work loose or cause trouble. Brakes may be attached to any (Type Z) Ore Car.

Mine Ore Loader

The was designed and developed by practical mining men. Their wide experience in handling ore and muck in underground mines qualified them to design a machine which did not have all the faults and disadvantages common to mechanical loaders, scrapers, and muckers, and that this was accomplished has been proved by years of operation.

This loader, due to superiority of design, is made more powerful and faster than any other loader doing similar work. It will operate in the smallest drifts and tunnels and can be shifted with ease from one mine tunnel to another. It has a digging width of approximately 6 feet.

The Mine Ore Loader is inexpensive to operate, low in air consumption, and is constructed to withstand the roughest use; having electric treated alloy steel castings throughout, anti-friction bearings, steel gears and heavy duty air motors designed especially to stand up under the severe requirements for mine and tunnel work. Ample lubrication for all moving parts has been carefully provided. The motor reduction gear cases and transmission gear case are lubricated through easily accessible plugs. All parts are thoroughly protected against possible damage.

Gasoline Locomotive

The (Gasoline) Locomotive is an economical, powerful unit for mine car haulage where tonnage handled warrants installation of means for mechanical conveyance.

The utilization of gasoline as the motive power in haulage, both in the mining and industrial fields, has effected such reductions in cost as to warrant favorable consideration of this method of handling wherever practical. Some of the advantages to be obtained from mechanical conveyance by means of gasoline powered mine locomotives are low first cost, ease of operation, readiness for immediate service, no expense when idle, and low operating costs. In most cases a considerable saving can be made using the gasoline powered mine locomotive in place of man or mule-powered haulage systems. The (Gasoline) Locomotive is built for maximum efficiency and will give long service under the most difficult operating conditions and withstand considerable rough usage.

The power plant consists of a standard automobile gasoline engine of about 60 to 85 horsepower with radiator, electric generator, self-starter, clutch, gear reduction, transmission, and reversing gear. Reversing gears and shafts run in ball bearings which are completely housed. In addition to the reversing gear provided by the standard motor, which gives only one reverse speed; another is added which reverses the entire power plant. Thus, this unit is so arranged that three speeds are available in either direction. Maximum speed is 10 miles per hour.

The (Gasoline) Locomotive frame is built up of heavy cast iron members, securely bolted together and carrying the four bearings of driver axles—mounted on roller bearings. Power is transmitted to drivers through steel sprockets and roller chain.

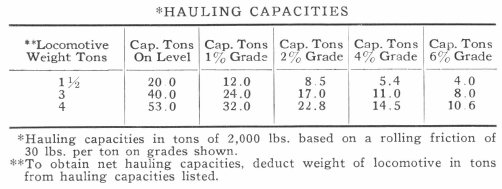

A hand brake is provided of sufficient power to hold any load which the locomotive will pull. This unit can be furnished for any reasonable track gauge and various hauling capacities may be obtained depending upon the percent grade where unit will be used.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.