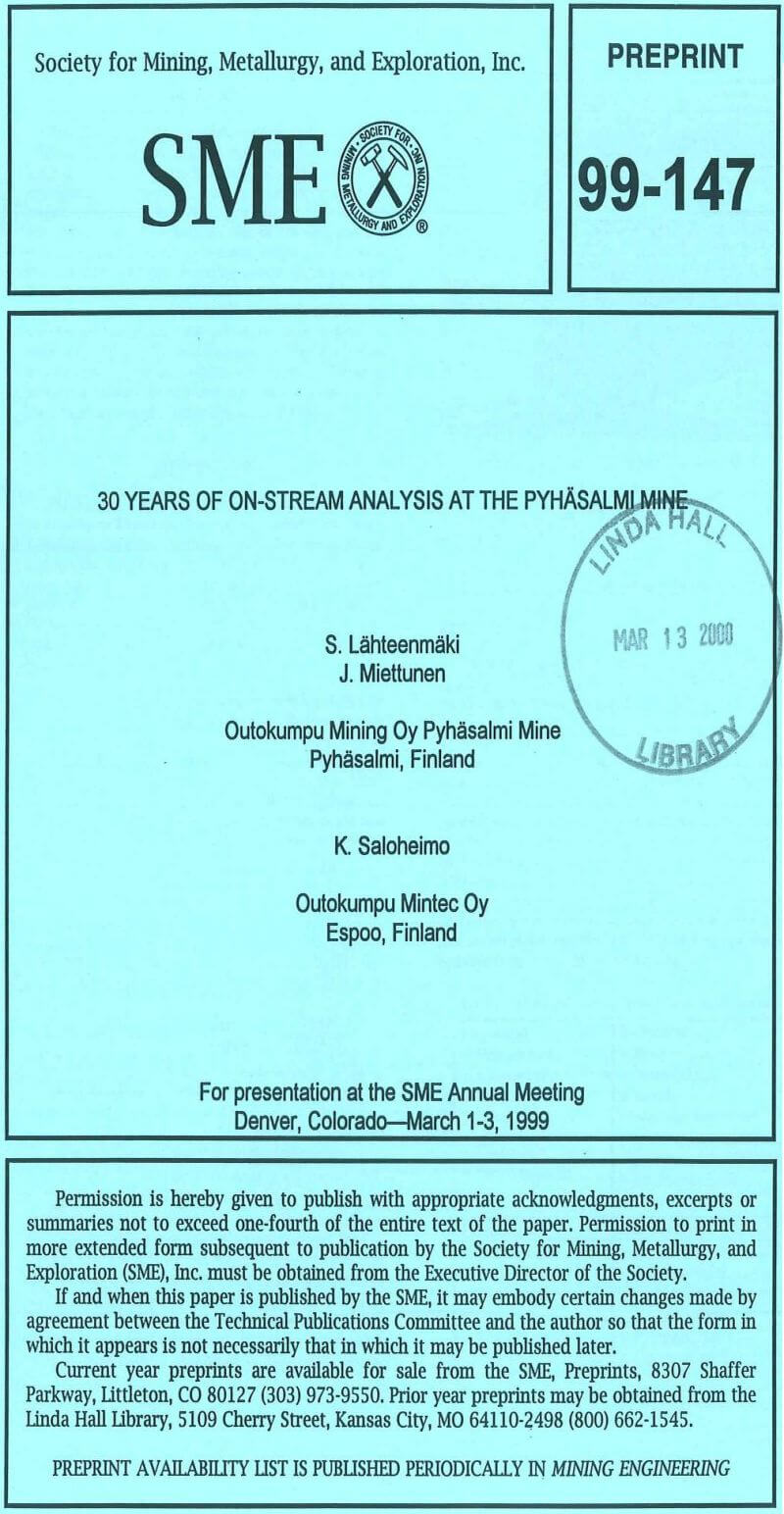

What are the benefits of having an OSA on-stream analyser? The assays are utilized for control in many ways, starting from individual control loops to overall optimization in the flotation circuits. Reagent dosages in the cleaner flotation stages are controlled by feedback from concentrate quality. For instance, the depressant in the zinc cleaner circuit is adjusted by to the sequence shown in Figure 6. If the cleaner concentrate or middling tails assays are outside set bounds, the depressant feed rate is increased/decreased in steps until the limits are reached. Within the limits, the reagent feed follows the deviation of the cleaner concentrate grade setpoint by a PI algorithm. The control sequence and its operator interface have been implemented using the Advanced Control Tools in the Proscon 2100 system.

The overall control of the flotation circuits is based on the economical quantities calculated from the feed, concentrate and tailings assays. The rougher tailings assays provide information on the balance of the rougher and scavenger circuits. They also serve as a fast measure of the overall recovery, to allow prompt reaction to disturbances. The sample lines at the cleaner flotation circuits are used for controlling the final concentrate quality and the circulating load back to scavenger flotation.

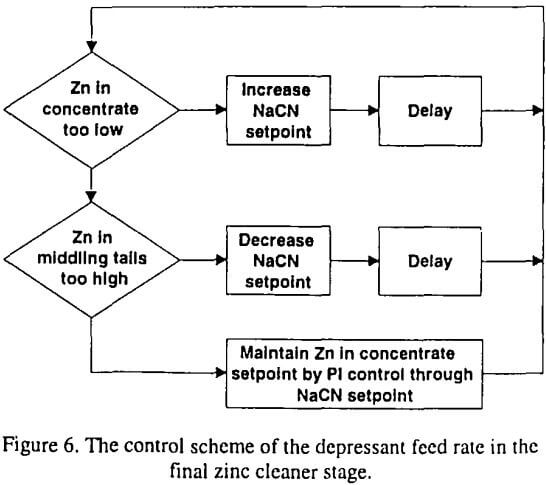

Using material balances and price formulas, the assays are converted into overall production and real time cash flow values for each flotation circuit. The cash flow is compared to a model value based on past history, and control actions are taken if the model targets are not reached. The balance between the recovery and concentrate grade is assessed by indices that are compared to the respective targets obtained from the model. The control actions have been defined to the main control variables of the circuit, including flotation cell level and air and chemical feed rates for rougher, scavenger and cleaner cells. The circuit is stabilized to normal operating bounds by several hierarchic rules that act in parallel with the optimizing rules. As an example, the

control sequence of the rougher flotation air in the copper flotation circuit is shown in Figure 7. More detailed accounts on the controls have been published elsewhere (Koivistoinen and Miettunen, 1984; Jamsa-Jounela 1995).

Benefits of on-stream analysis

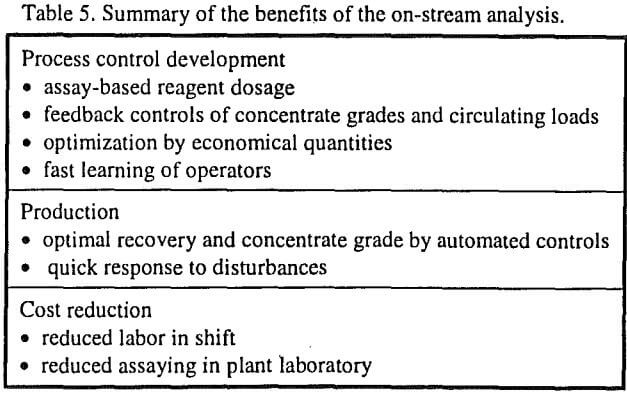

The automatic controls based on the on-line assays have stabilized the process against disturbances and ore variations. As the process has been under constant development over the years, it is difficult to calculate the benefits of the assay-based control in quantitative terms. An early investigation showed a 0.5% increase in Cu recovery (Leppala et al., 1970).

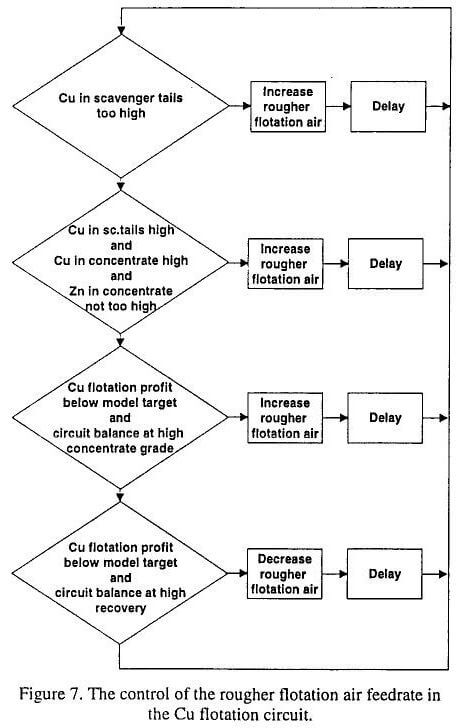

There is one recorded event in 1983 when both analyzers were down over a weekend as their computer system was upgraded. The plant was controlled by manual assays. The composite sample analyses during these three days are shown in Table 4, along with the corresponding data in the preceding three weeks. The average ore grades remained the same for the two periods. When calculated into value of production, the comparison shows that 2.3% of the value of the copper concentrate production was lost into tailings and 3.0% of the zinc concentrate production to the tailings or copper concentrate, in the absence of the on-line assays. When scaled to the yearly 850,000 tons production, these figures amounted to roughly 400,000 USD annually. The pyrite and lead flotation circuits were not running at that time.

A significant benefit of the analyzers is the reduced need for laboratory assaying. At present, the composite metallurgical samples are collected and analyzed only three times per week. The material balances are calculated on a shift basis by the average on-stream assays. If the composite sample assay shows a significant deviation from the calculated average, the balance values are corrected accordingly.

The on-stream analysis has been invaluable in developing the process control. Process experiments have been conducted with the results readily available. The understanding of the behavior of the complicated process has accumulated based on the assays. The operators have learnt their skills by the immediate feedback of their control actions, given by the assays and calculated economic quantities.

The number of people needed in the shift has been constantly decreasing with the increasing process control. Back in the late sixties the flotation required 8 people at the plant and in the laboratory whereas nowadays all four flotation circuits are handled by 2 operators and one foreman dedicated 50% for flotation. They handle the routine maintenance work of the analyzers as well.