Factors Affecting Ball Mill Grinding Efficiency

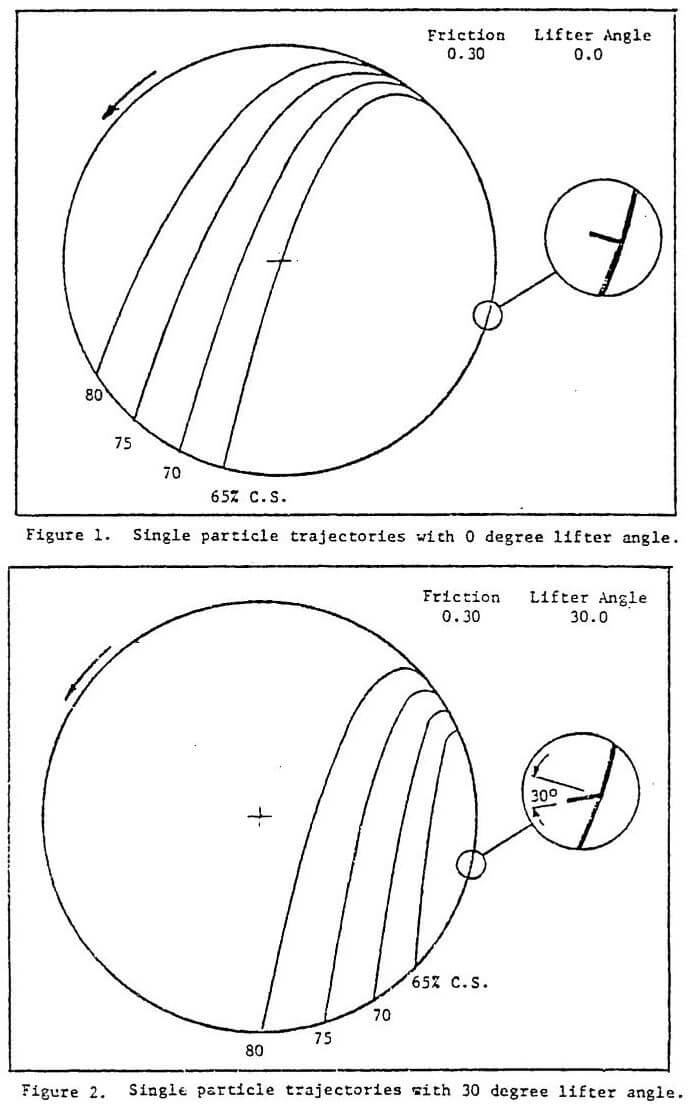

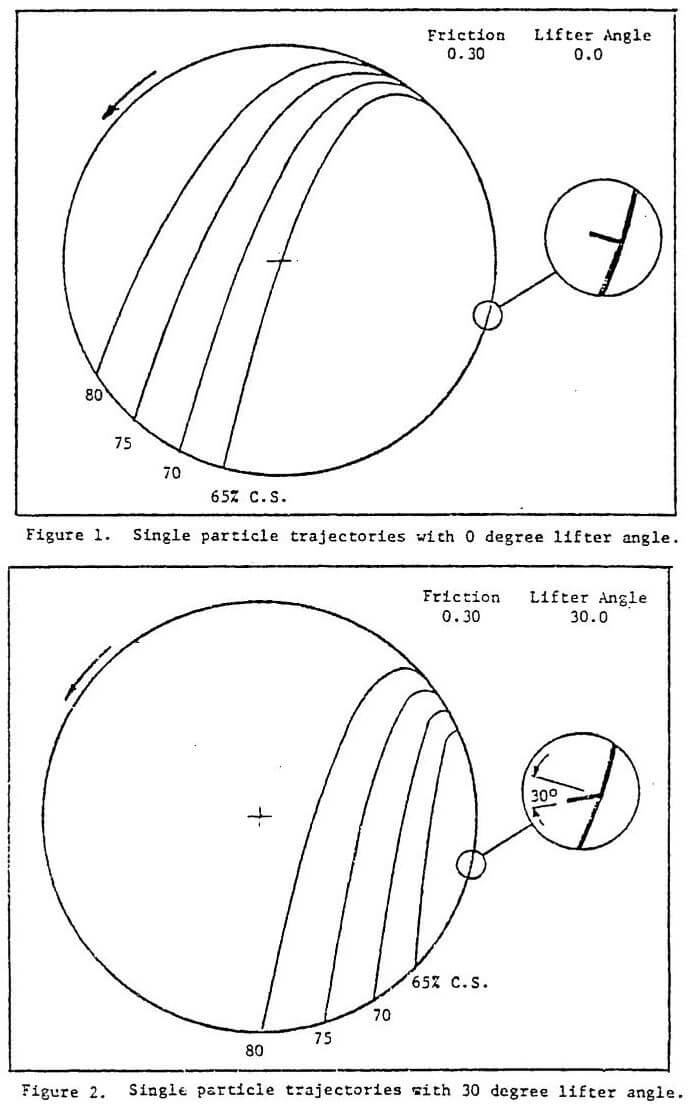

The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed

The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed

With particular reference to mill size, it is apparent that a change in diameter in a large mill is relatively far less significant than the

Precipitates mixed with diatomaceous earth from the precipitation filter unit are dried in a filter press and mixed with borax and soda ash. This mixture

Floatable and non-floatable particles follow different sequence for transport from the pulp to the froth and from the froth out of the cell. For floatable

Application of value engineering techniques to grinding process modelling led to the identification of two basic functions of the ball mill-classifier circuit. In terms of

These depressants are organic mixtures reacted with inorganic salts. They have found application for depression of oxidized pyrite, marcasite and pyrrhotite during the flotation of

The ultrasonic treatment unit consists of an inclined, flat bottomed metal trough, usually made of stainless steel or aluminum, with the ultrasonic transducer attached near

Carbon strip circuits present a particularly challenging scale inhibition problem. Many of the factors that tend to promote scaling are present in these systems. For

Environmental audits can serve many purposes. One way in which an audit may be used is to assess an operating company’s compliance with environmental laws

In open pit mine planning, the design of the most profitable ultimate pit limit is a prerequisite to developing a feasible mining sequence. Presently, the