Molybdenum Ore Processing by Flotation

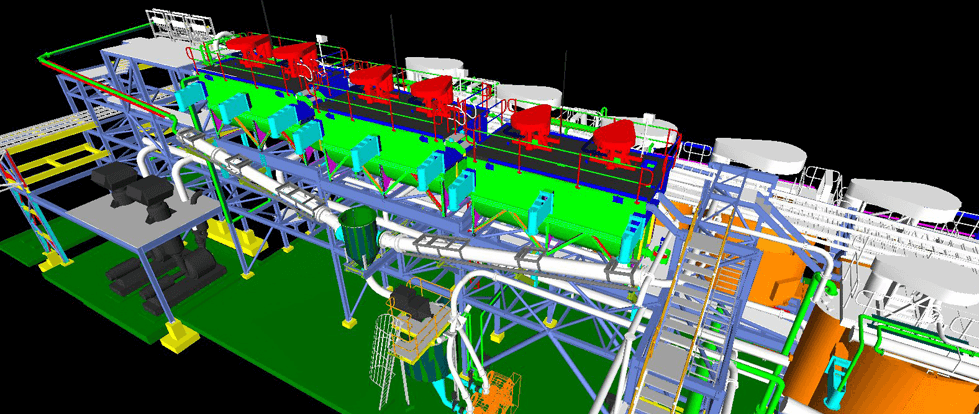

This molybdenum flotation circuit, based on 250-500 tons per 24 hours is designed for low-grade molybdenum ore having high-grade streaks and with pyrite-quartz gangue. It is

This molybdenum flotation circuit, based on 250-500 tons per 24 hours is designed for low-grade molybdenum ore having high-grade streaks and with pyrite-quartz gangue. It is

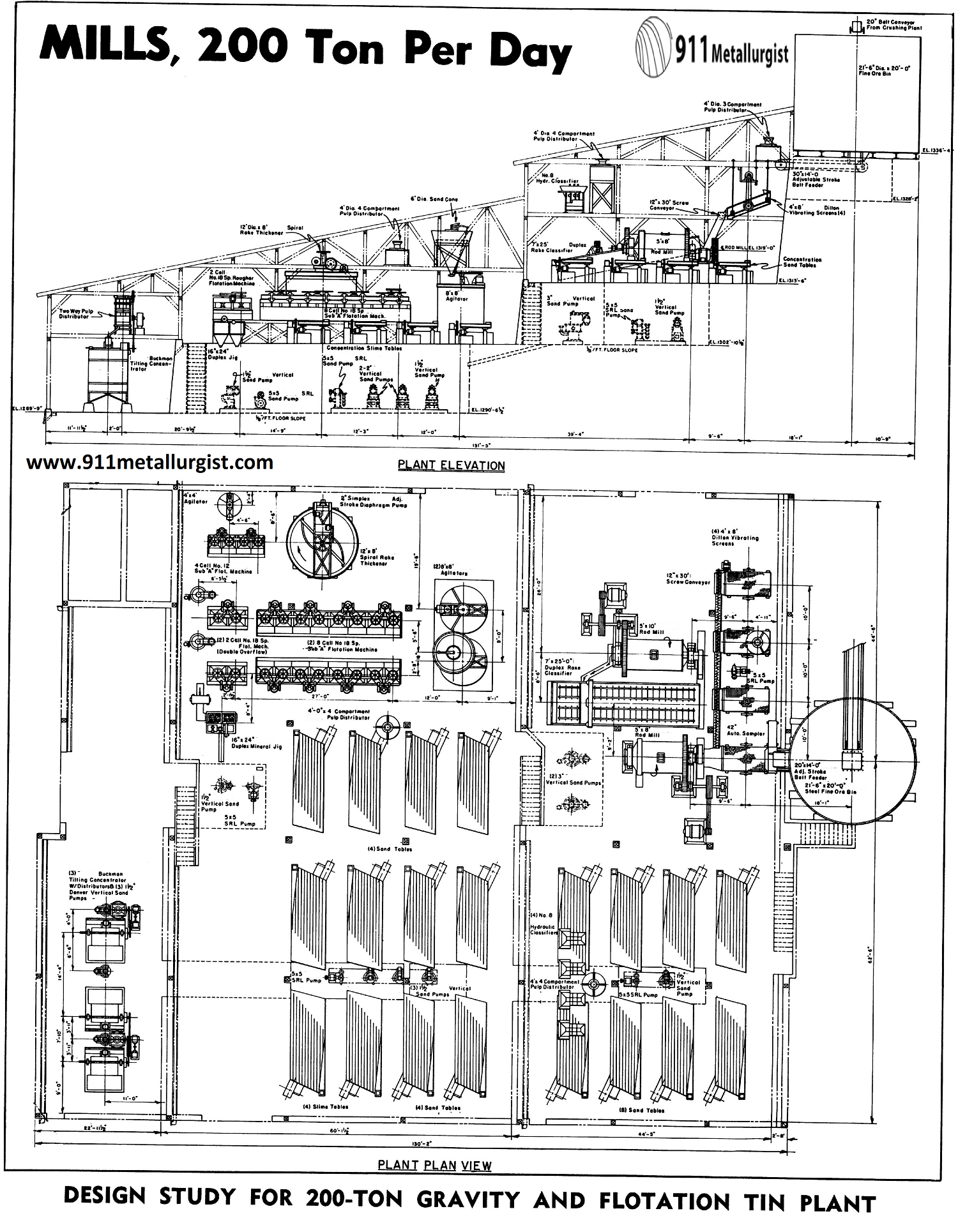

Design Study for 400-Ton per Day Flotation Plant The sulphur mill was designed for best adaptation to the mill site available. The design provided for simplicity of

The scarcity of both skilled construction and operating labor in the region, caused the customer to under-score the terms “fool-proof” and “simplicity” in the instructions

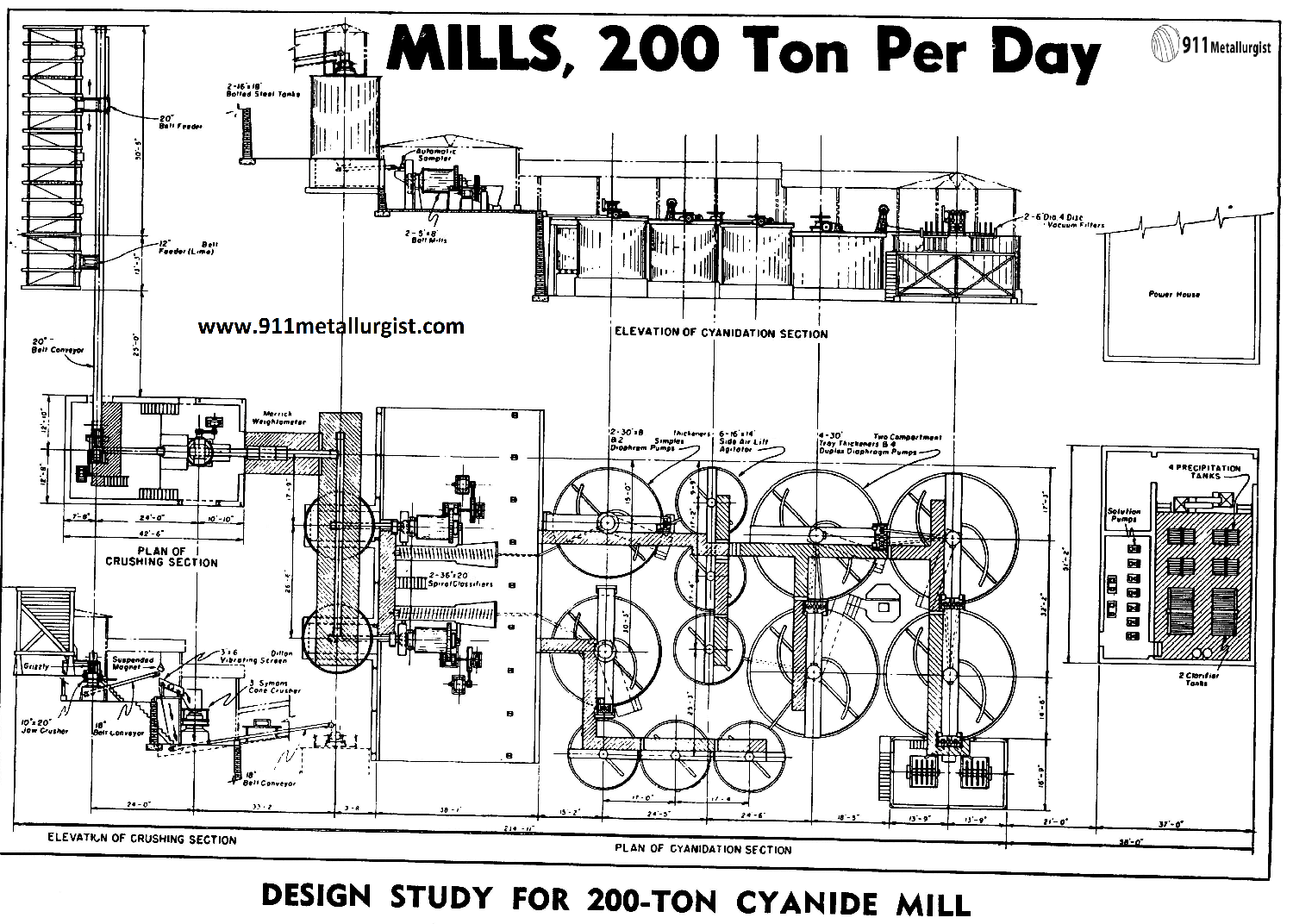

The gold cyanide leaching mill site is centrally located with respect to the mine, water supply and improved highway. This selection reduced both the length

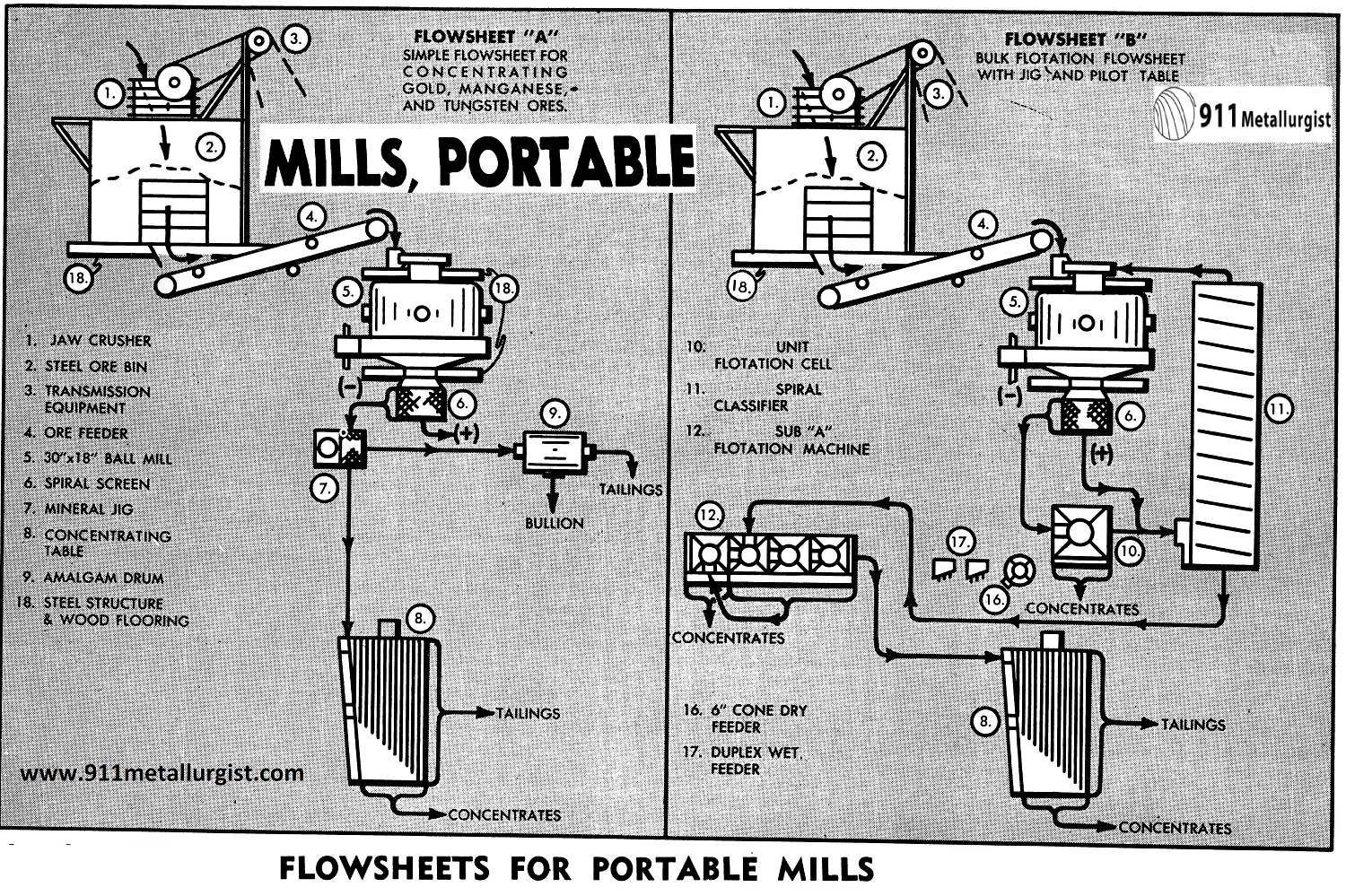

Much interest is being shown by both small operators and big mining companies in small portable and semi-portable milling plants. The small operator, perhaps lacking an

The concentration of mica is an unusual problem due to sheet-like, flaky structure of the minerals. Premium grades of mica demand a sufficiently high price

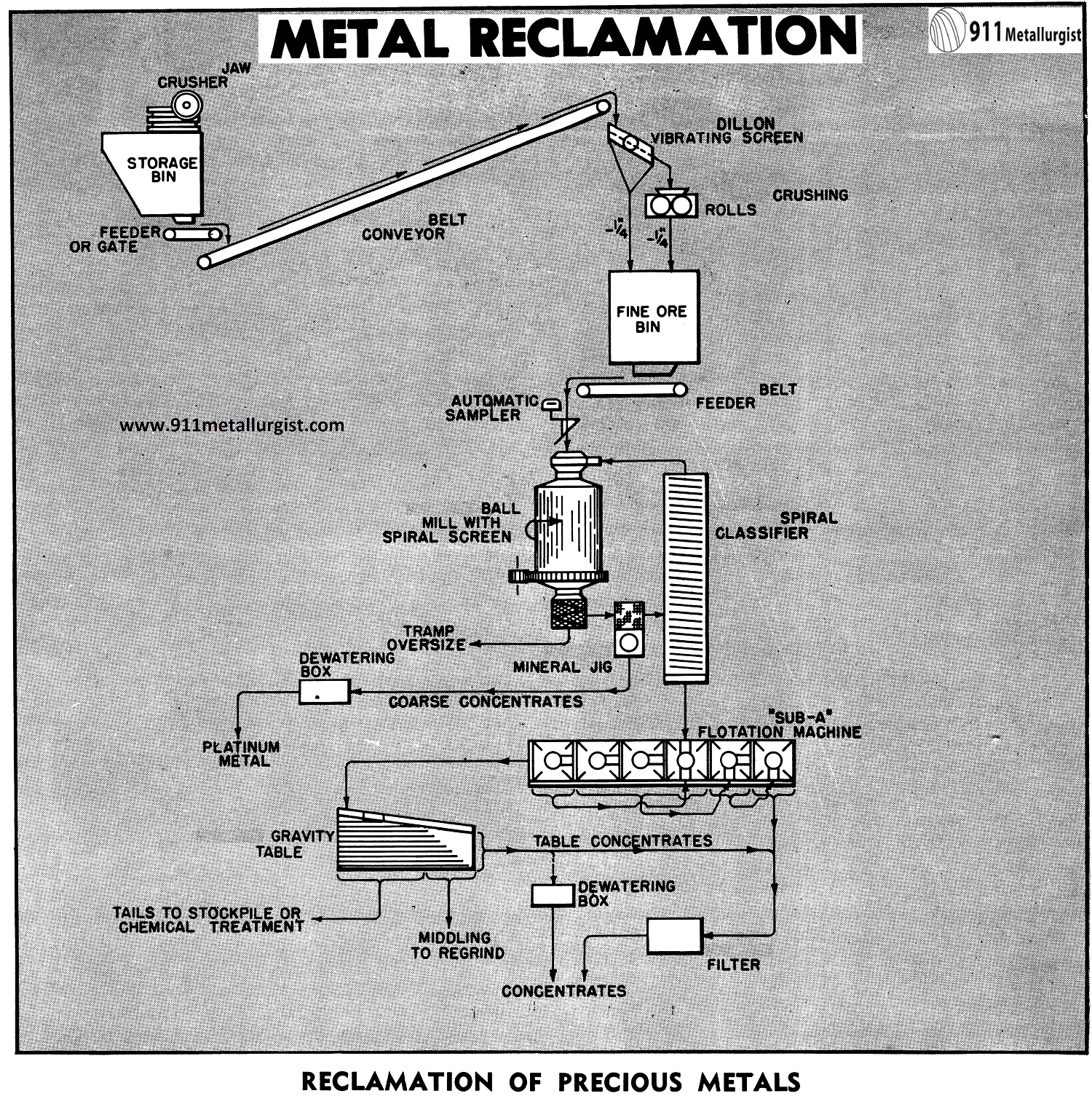

During the manufacture of fiberglass the platinum-rhodium bushings used for the extrusion of the fiberglass tend to vaporize at high temperatures and the metal is

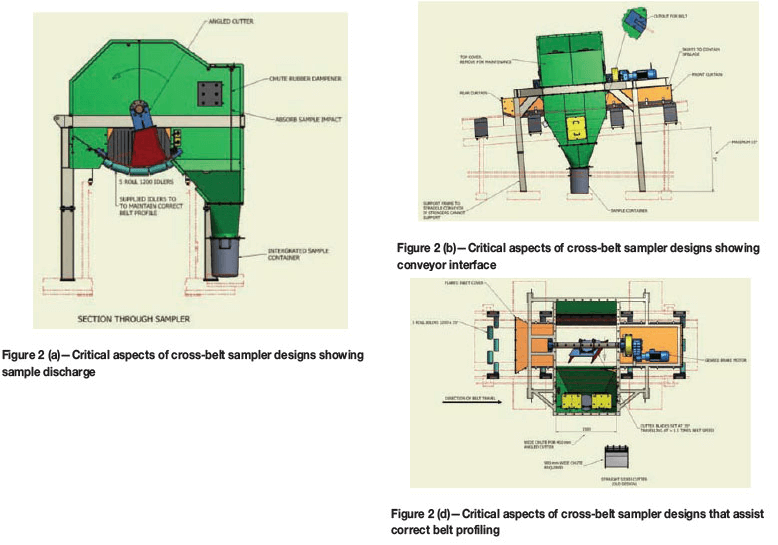

Example Cross Belt Samplers Supplier CROSS-BELT SAMPLER FOR MATERIALS CONVEYED ON A BELT CONVEYOR

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.

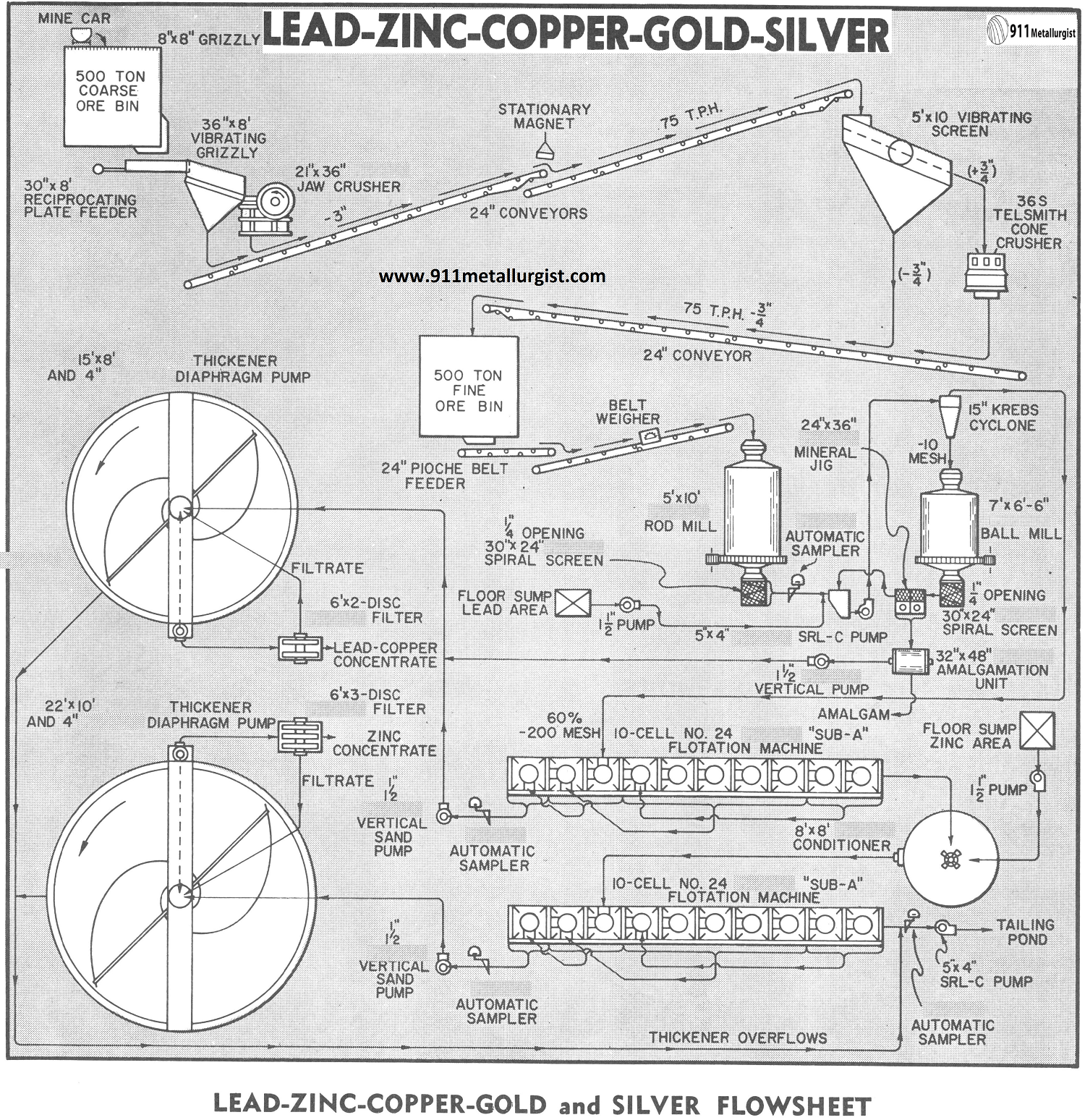

The flowsheet in this study was designed to treat 500 tons per day of a complex base metal ore containing gold and silver values. The