Peripheral Discharge Ball Mills -Theory and Practice

These notes are based on observations made while on a recent trip through the West, for the purpose of studying the practical operation of the

These notes are based on observations made while on a recent trip through the West, for the purpose of studying the practical operation of the

The basic factors, principles and variables affecting froth flotation are enumerated in condensed form below: Ore. (a) Mineralogical character. (b) Fineness of grinding. (c) Method

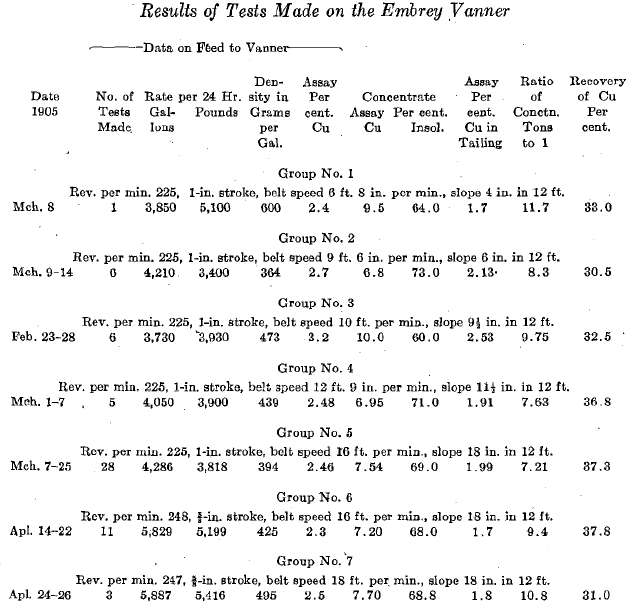

The principal object of this paper is to present data on the development of the revolving convex round table as a concentrator for the through

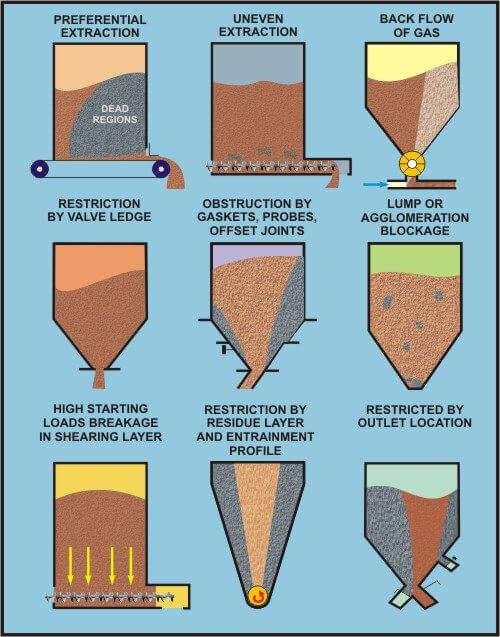

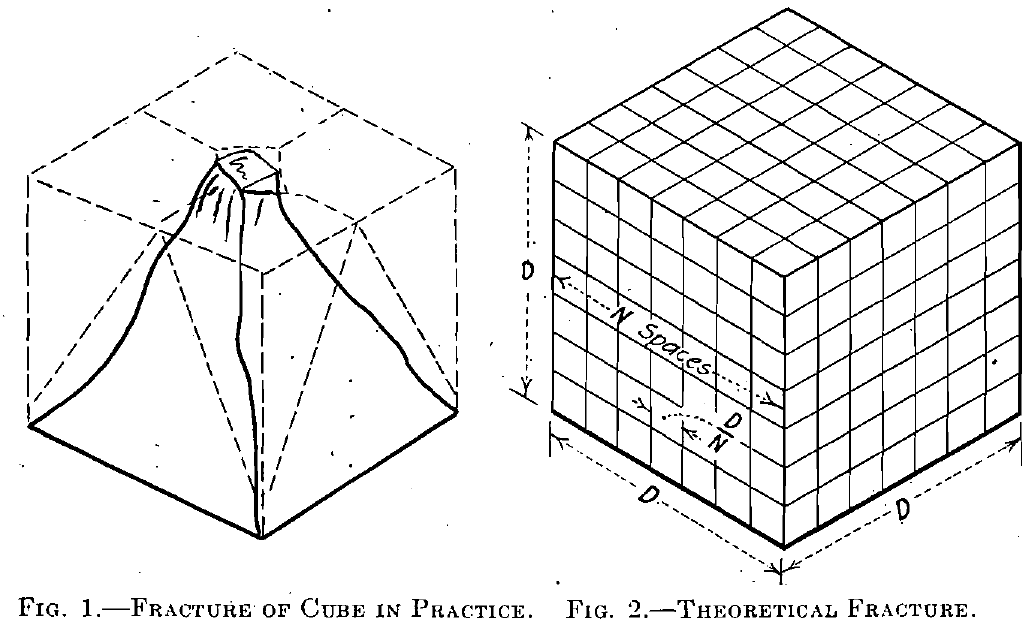

The performance of Bulk storage hoppers and silos is sensitive to the nature of their contents so consideration must first be given to the physical

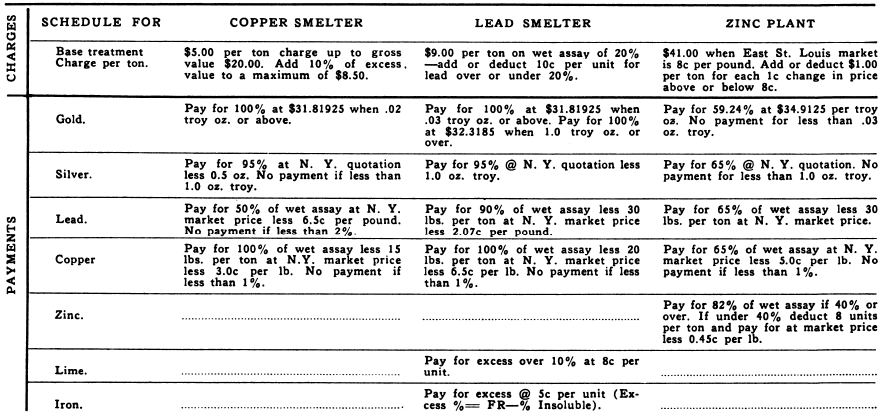

The object of this Concentrate Marketing post is to draw attention to the benefits of modern milling practice, thus enabling the miner and mill operator to

Flotation, in its latest phase, is a process of concentrating ores by frothing. When crushed ore, previously mixed with water and a relatively minute addition

Rittinger’s theory and law of the energy expended in crushing of rock is that the work of crushing is proportional to the reduction in diameter;

Agitation capacity based on 36 to 48 hours of agitation time. Thickener area based on 6 to 7 square feet per ton of

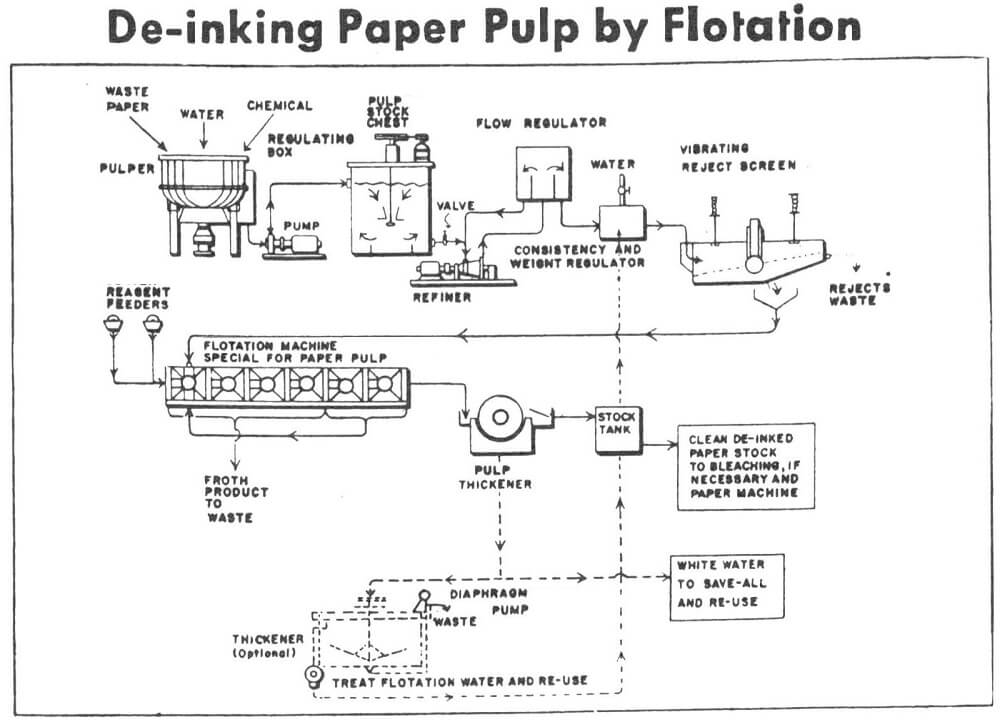

The pulping consisted of disintegration of the wastepaper structure and dispersion of the fibers. The disintegration was accomplished by conditioning 250 grams of wastepaper, under