Cassiterite Flotation – Tin Oxide

Table of ContentsFlotation of Tin Ore SlimesDirect Tin Flotation The nominal size range for cassiterite flotation is between 2 and 100 microns. The top size

Table of ContentsFlotation of Tin Ore SlimesDirect Tin Flotation The nominal size range for cassiterite flotation is between 2 and 100 microns. The top size

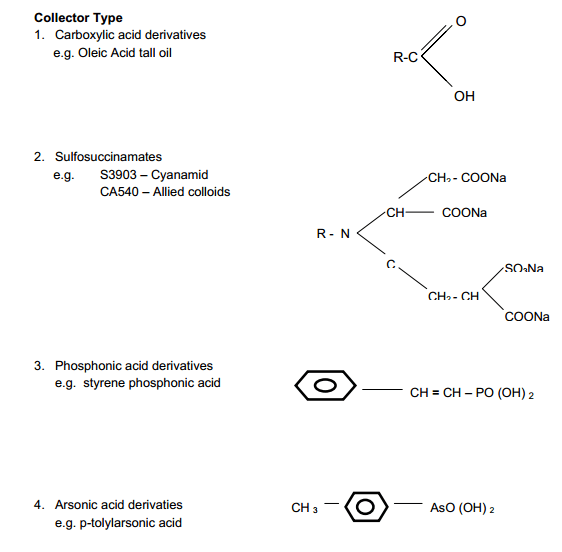

Table of ContentsFlotation with Phosphonic & Arsonic Acids CollectorsAdvanced Flotation with Ramification-Carrier Flotation ProcessCentrifugal separator – flotation – magnetic separationMagnetic Separation / FlotationShaking Table /

Table of ContentsPlanning the lab flotation test:Flotation ReagentsFlotation Equipment PreparationSample OriginBatch Laboratory Test PlantContinuous Laboratory Test Plant Batch Laboratory Flotation Testing starts from the 3

This shows an good video example of the cause of tailings dam failures.

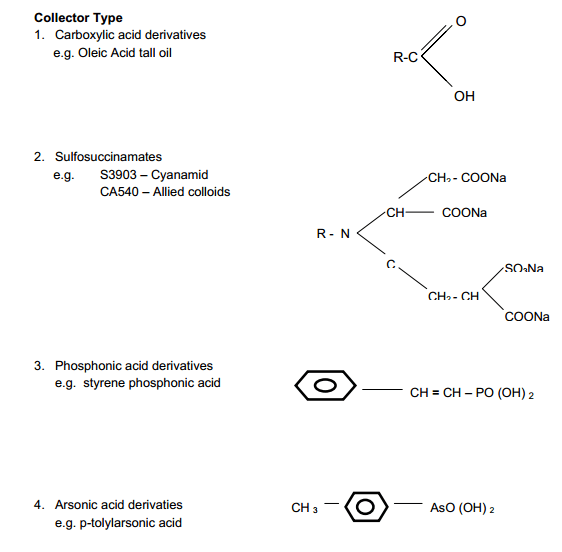

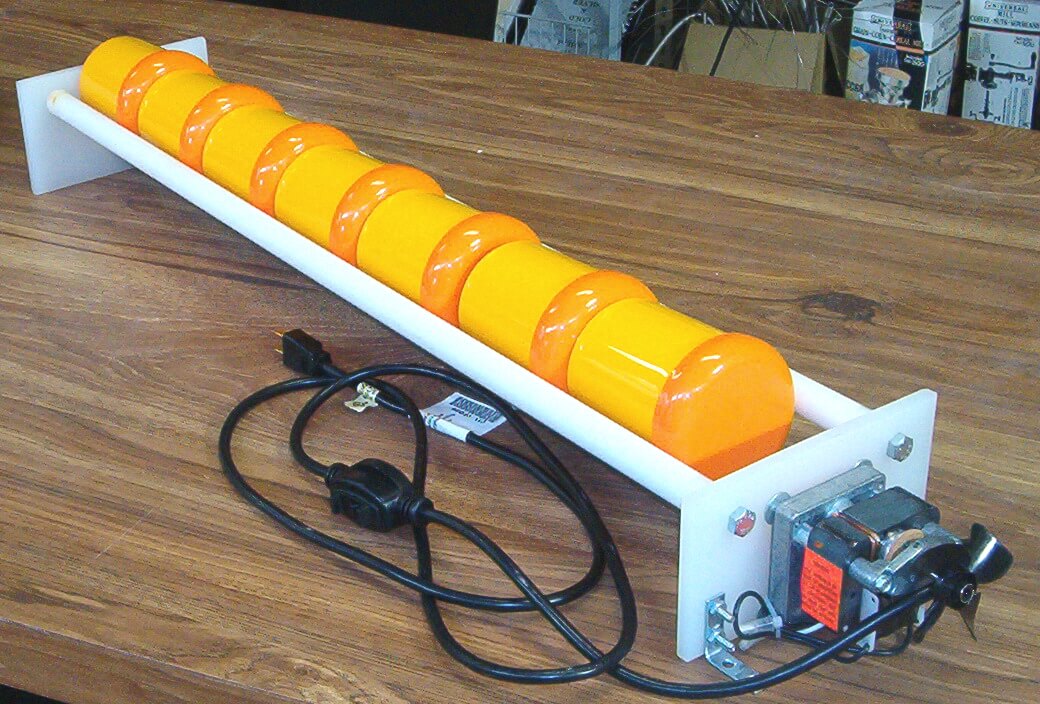

Rods are loaded or charged into a Rod Mill using a mechanised charger. The rod charger with extendable boom moves rods safely inside the trommel/trunnion before charging

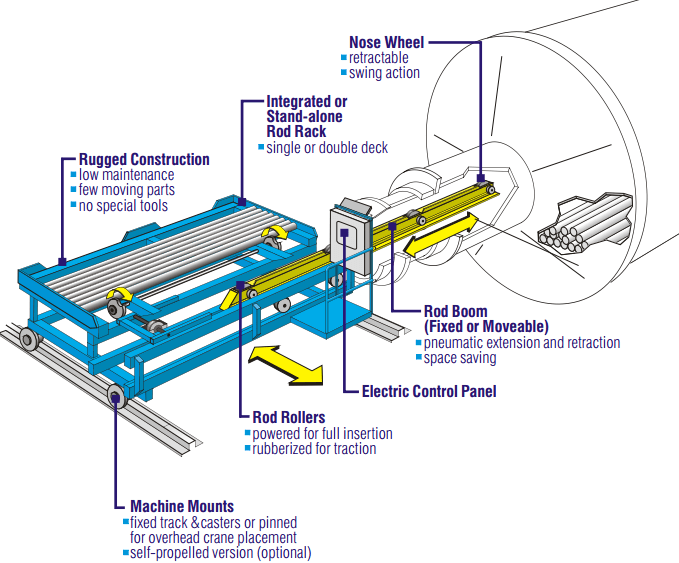

Table of ContentsTypes of Ball Mills Ball Mill GrindingExample of Plant Capacity GainsBall Mill SpecificationsCompare Type of Mill DischargeGrate Discharge Ball Mill CapacitiesGrate Discharge Ball Mill

1) For better Column Leaching, Agglomerate ore if required. The procedure is to cure for recommended time period. During this time the ore should be kept damp via

Here is a method on how to conduct a cyanidation bottle roll test AKA Cyanide Gold Extraction Process: Riffle out 400 grams of the ore. Grind

Table of ContentsLaboratory leaching procedures“Old” Gold Leaching Method List Equipment Required to Perform of a Standard Bottle Leach Test Winchester bottles, with tops Plastic tape

Methods of leaching sulphide ores can be: in absence of oxidizing agents in presence of oxidizing agents Bacterial leaching Absence of oxidizing agents Acid leaching: