Optimum Mill Liner Spacing | Design Effectiveness SAG

The images (chart) below is industry standard when it comes to the relationship between a mill liner’s lifter bar height and the lifter to lifter

The images (chart) below is industry standard when it comes to the relationship between a mill liner’s lifter bar height and the lifter to lifter

Here is cone crusher arranged with a Level Sensor interlocked with the feed conveyor. It keeps the crusher feed cavity full for best choke feeding.

King Gee, a reputable clothing company, has released the revolutionary new G2 Compression Workwear. Ideal for miners, it “targets key muscles to reduce soreness and improves

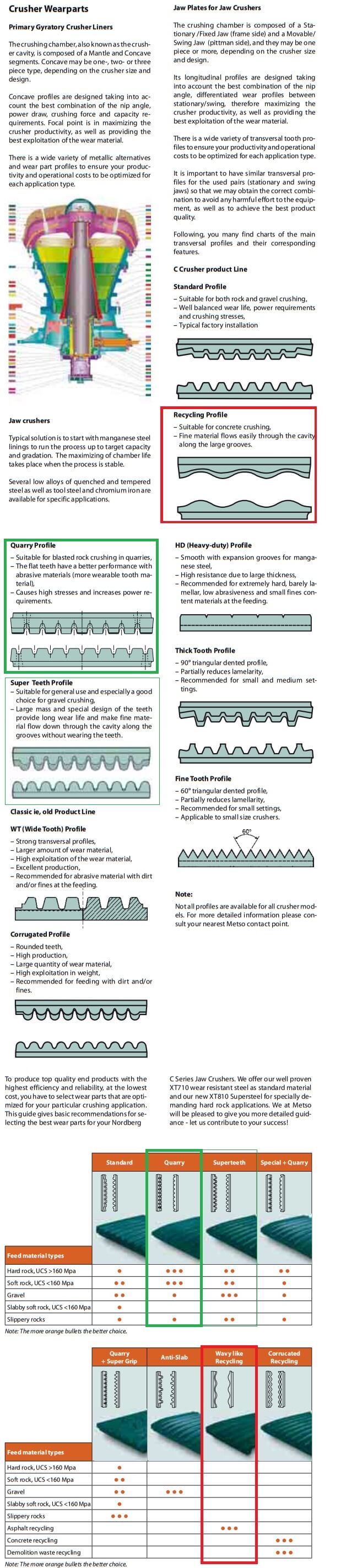

A client needed finer crush out of his Jaw Crushers. I proposed this literature from Metso.com to help him select a jaw liner set. Designing

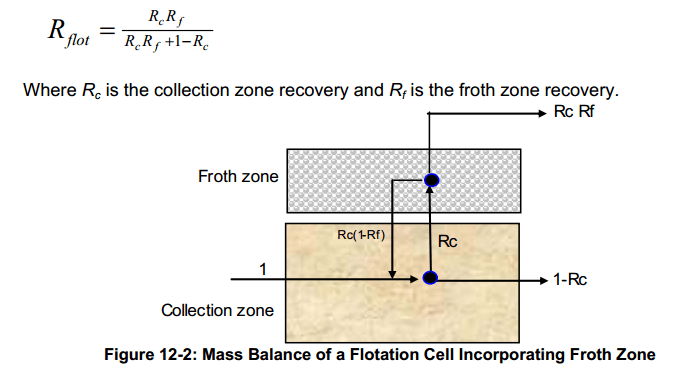

Although the model has been tested against only a limited amount of data the results shown in Figure 6 suggest that the model can be

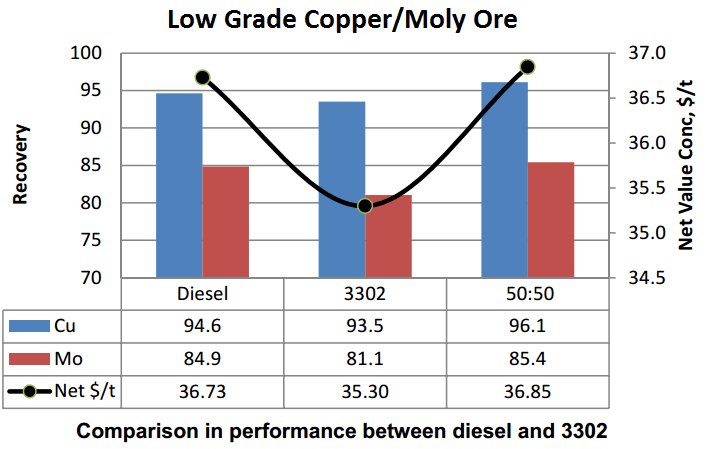

Are design or custom blends better than standard and cheaper fuel oil? Because of the high cost of the ‘designer or custom blend’ reagents, a

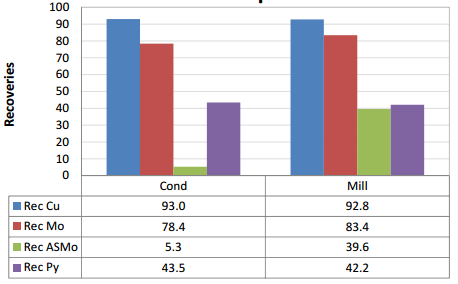

Where is Molybdenum best collected by its collector, Grinding or Conditioning? The protocols of the testwork were done such that a comparison could be made between adding the

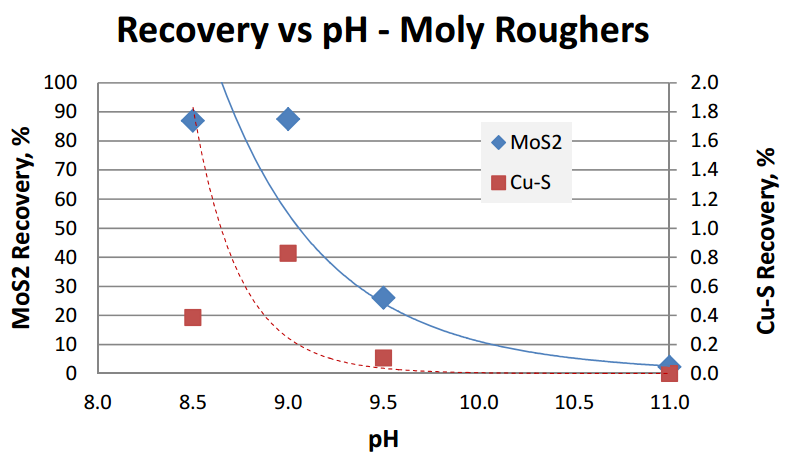

pH was varied in the moly flotation in roughers while attempting to maintain a eH in the low -500 mV. The results of the test,

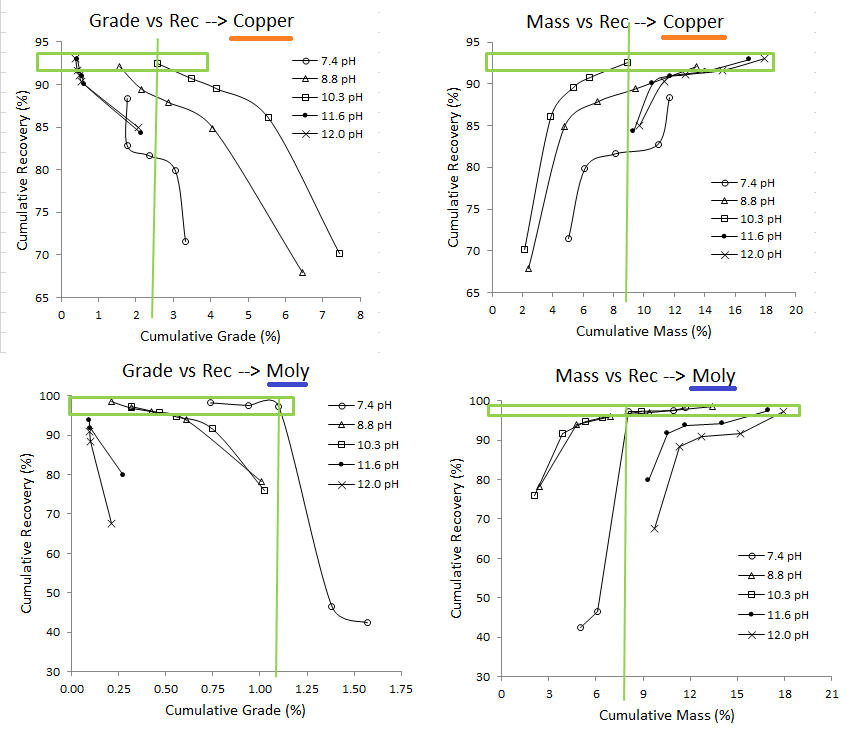

Graphic Conclusions of this particular set of flotation tests: Copper – Irrelevant of pH, with enough float time and reagents, you usually reach a terminal

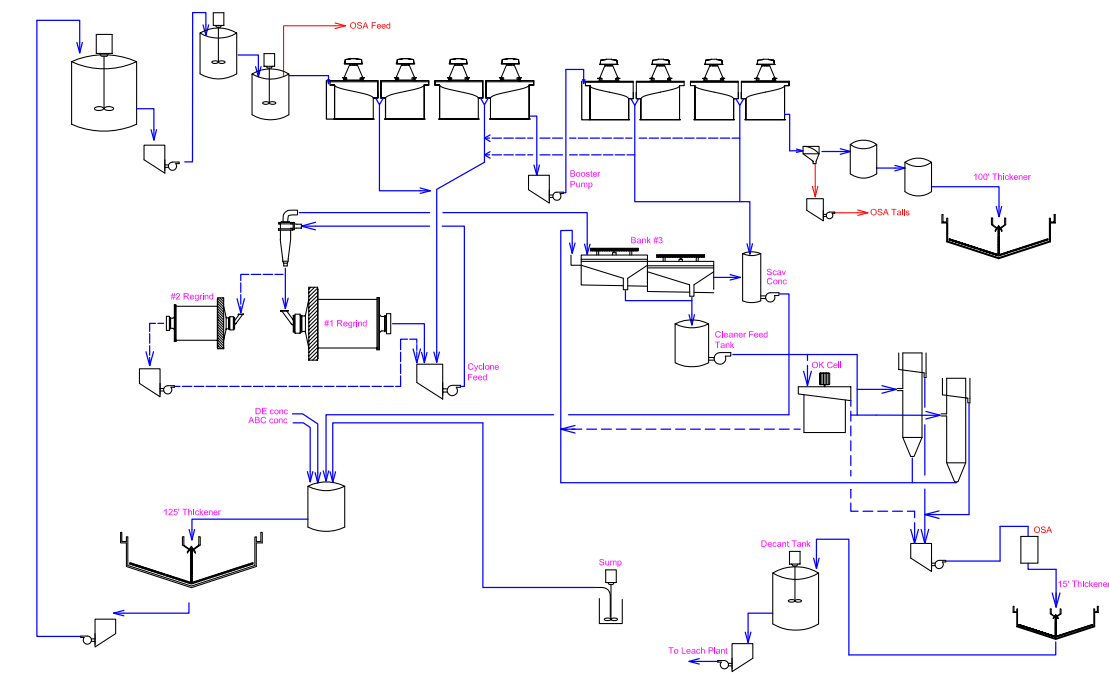

Here is a Proven Cu Mo Separation Circuit Flowsheet (by flotation) many will model after. It is used a Canada’s largest copper-molybdenum mine. It uses