Maintenance and Operation of Mining Machinery

Modern high capacity underground mining machinery is a complex of mechanical, electrical and hydraulic components which have greatly increased capability over similar components of mining

Modern high capacity underground mining machinery is a complex of mechanical, electrical and hydraulic components which have greatly increased capability over similar components of mining

The stress distribution around single and multiple underground openings has been determined both from theory and from photoelastic laboratory model studies. These determinations require certain

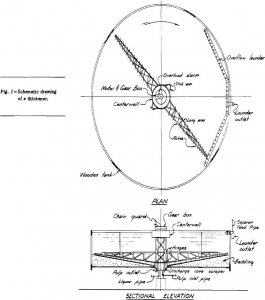

The use of a series of thickeners for washing of the slime fraction of a leached ore is not uncommon in the uranium industry; however,

Electronic Waste Recycling An Overview Like most mining ventures under taken by amateurs, processing e-waste can be a quick way to loss all your money.

The Cretaceous plant at the Hill Annex mine of the Jones & Laughlin Steel Corp. was designed with a wet autogenous mill for grinding low

Starting with rutile, containing more than 95% TiO2 and of the proper particle size, the commercial production of titanium tetrachloride via fluidized bed chlorination is

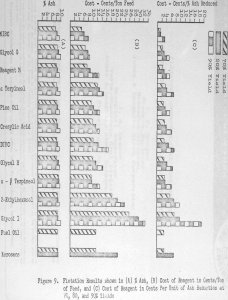

This paper presents the results of a study in which commercially available forms of various reagents were used as flotation frothers. Flotation procedures which would

The dewatering steps discussed will include gravity settling, centrifugal dewatering, vacuum filtration, and thermal drying. Of these dewatering steps particular attention will be given to

Vertical shaft furnace design and operation have their roots deep in antiquity. There is substantial evidence to indicate that iron was reduced from its oxides

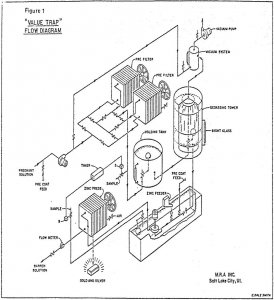

The removal of metal values from cyanide solutions, fortunately, can be done in several ways. The oldest practiced method is, cementation with zinc, or Merrill-Crowe.