The gold deposits grouped together under the name of “ placers ” comprise sands, gravels, or any loosely coherent or non-coherent alluvial beds containing gold. They have accumulated owing to the action of running water, in the beds of rivers, or on the adjoining inundation plains, or on sea beaches. They fall naturally into two groups, between which no strict line of demarcation exists. These are:

- Shallow or modern gold placers, which are usually in or near existing rivers, and have not yet been covered by other deposits. In certain arctic districts, the gravel beds have been formed by the action of glaciers.

- Deep level or ancient placers, which now lie buried beneath an accumulation of debris or coherent rock, the rivers by which they were formed having often been deflected into other channels by more or less extensive changes in the physical geography of the district in which they existed. Beach deposits occur in each subdivision.

From the earliest times to the present day, the mining of shallow placer gold deposits has probably yielded more gold in the aggregate than has been derived from all other sources put together. They contain metallic gold in fragments of all sizes, ranging from the finest dust to nuggets weighing thousands of ounces. Auriferous sands are found in the beds of most rivers which flow during any part of their course through a region composed of crystalline rocks. If the rivers have rocky beds, gold may be found in the crevices, caught in natural riffles, and the whole may subsequently be covered by beds of sand.

Gold also occurs in river bars and banks, in the river “ flats,” or inundation plains, in the dry beds of streams which only flow after heavy rains (“gulch diggings”), in terrace gravels on the sides of valleys high above the present level of the water (“ bench diggings”), and on the sides and tops of hills (“hill diggings”). The last two subdivisions are evidently ancient rather than modern deposits. The gravels may contain boulders of any size, up to several feet in diameter, or may shade off into fine sand, while sandy clays, especially if on the bed-rock, are frequently very rich. In the Urals, the placer deposits often consist of heavy clays, while others are formed of waterworn fragments of auriferous quartz, talcose and chloritic schists, serpentine, greenstone. Gold occurs under very various conditions in these deposits. It may occur in the grassroots on inundation plains, or near the surface of the gravels in river beds, or dispersed through the whole thickness of a stratum. More commonly, however, the lowest part of the superficial beds, just above “bed-rock” (the country-rock of the district), is the richest. In hollows, cracks, and crevices of the bed-rock, or, if it is soft and decomposed, in the substance of the upper part of the rock itself, to the depth of 1 or 2 feet, gold occurs in the greatest quantities. In pipe-clays just above bedrock, in Victoria, it was not uncommon to find 12 ozs. of gold or more in a single tubful of ” dirt,” and similar rich bed-rock deposits occur in California. The depth at which bedrock is found varies greatly; it may crop out at the surface, or it may be buried beneath hundreds of feet of gravel, and great variations occur even in a single district. In Siberia, however, the thickness of the gravel is usually less than 3 feet thick and is rarely more than 12 feet.

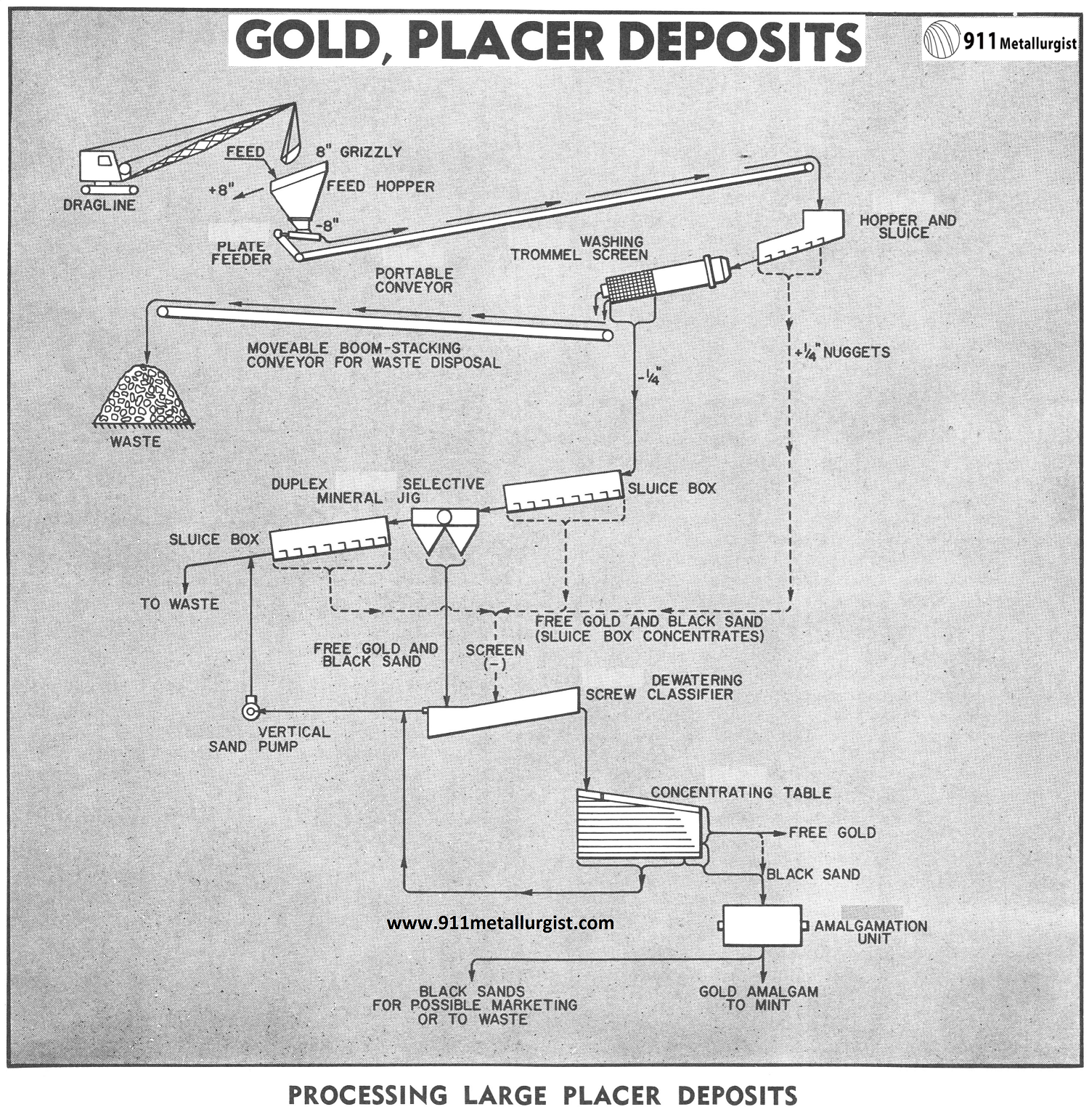

How to Recover Gold from Placers in Mining

The gravel obtained from any placer deposit is, with exceptions, ultimately all treated alike, but the mode of winning the dirt varies with the necessities of the case. On flats and bars, the surface gravel, if rich enough, is loosened with pick and shovel, and then washed. If only the part just above the bedrock will pay for treatment, it is reached by ” stripping,” or, if covered by too great a thickness of barren material, shafts are sunk, and short levels run from the bottoms of them in all directions. If the nature of the ground permits it, tunnels are run without shafts, and the rich gravel is then followed from the surface, wherever it is found. This system was much practiced in the early days in California, although now seldom to be seen in operation; it was called “coyoting,” from the coyote, which lives in holes in the ground. When water was encountered in the shaft, it was drawn out by a bucket, until it came in too fast, when the claim was abandoned. In California, in somewhat later times, efforts were made to reach the gold in the river beds, by deflecting the streams of water from their courses, and in other ways. These methods will be briefly described under the head “ River Mining.” In Siberia and in the Yukon district the gravels are perennially frozen, and are thawed with steam jets or wood fires set at the bottom of shafts and at the ends of the drifts, and are then taken out with pick and shovel.

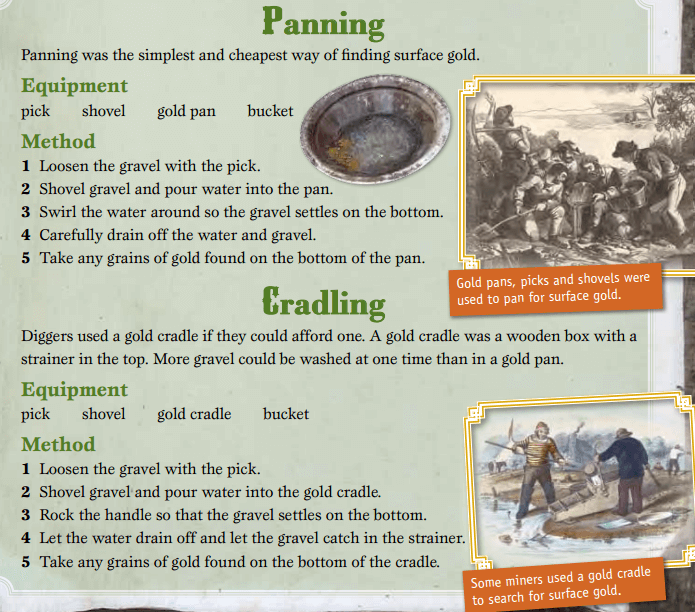

Methods of Washing the Gravel with Pan

When the existence of gold in the placers of California and Australia first became known, the diggers were not acquainted with any apparatus which was well adapted to extract the metal. The household pan was used everywhere to wash the gravel, and though, in its original form, it was a difficult implement to use efficiently, it has retained its place in both countries for prospecting and also for washing small quantities of rich material, however they may have been obtained. The pan is usually made of stiff sheet-iron, is flat-bottomed and circular, and at bottom 12 to 14 inches in diameter. The sides slope outwards at an angle of about 30° to the bottom, and are about 5 inches wide. A riffle is a useful addition, formed by the thickening or bulging inwards of the side, situated about half-way up the latter and running about half-way round the pan. The method of using this pan embraces several operations. First, it is filled to about two-thirds of its capacity with pay-dirt, of which it then contains from one-fifth to one-quarter of a cubic foot. It is then placed at the bottom of a water-hole or convenient stream, and the dirt is thoroughly broken up with both hands, care being taken not to leave any lumps of clay. As soon as the contents of the pan are reduced to the consistency of soft mud, the pan is grasped with both hands a little behind its greater diameter, inclined away from the operator, raised until the dirt is only just covered with water, and shaken from side to side, while a slight oscillatory circular motion is also imparted to it. The mud and fine sand are soon obtained in suspension in the water, and gradually pass over the far edge, which is lowered more and more, until little but the stones, coarse particles of sand, black sand, and gold is left. The larger stones lie on the top and are removed by hand. The final stage consists in lifting the pan with a little water in it, and by a movement of the wrist, something like that used in vanning, causing the material to be spread out by the water in a comet shape, in the angle of the pan. The “colours”—i.e., yellow specks of gold—are seen at the extreme head of the comet, and also occur in the succeeding inch or two, mixed with the black sand, while the quartz-sand forms the remainder of the tail and is scraped or washed off. The gold is separated from the black sand by (a) amalgamation with mercury, or (b) drying and blowing away the black sand, a wasteful process. Liquid amalgam is readily separated from sand, and the mercury is then driven off by heat.

Batea Pan

The Batea differs from the miner’s pan in not having a flat bottom. It is of wood turned in a lathe, about 20 inches in diameter, conical, or more rarely basin-shaped, and about 3 inches deep in the centre, so that the angle at the apex is about 160°. The gold collects at the lowest point and clings to the wooden surface under conditions when it would slide over iron.

The batea consequently is more rapid and effective in obtaining a “ prospect ” than the pan, especially when the gold is fine, but is less frequently used in the United States and Australia. The best material for the batea is mahogany cut with the direction of the grain vertical to the surface of the implement. It had its origin in South America and is especially favored by the negro race.

Prospecting Through

This instrument is used in the far east, especially by the Chinese, Malays, Annamites, &c. It is made of wood and is shaped in the form of a very flat reversed rooftop, the angle between the long sides being about 150°. In place of a circular movement of the water an alternating rocking motion is used, the water flowing up and down. The instrument is easily handled but is very slow.

Horn Spoons cut out of black ox-horns have been used by prospectors, especially to finish the work begun by the pan. The surface holds the gold well and shows “color” very readily.

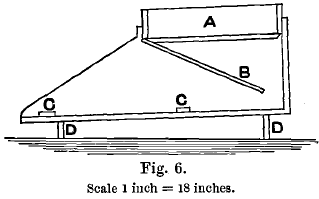

Gold Cradle or Rocker Box

The Cradle or Rocker was introduced in California soon after the first rush to the diggings took place in 1849.

It consists of a rectangular wooden box, about 3 feet long and 18 inches wide, resting on two rockers (D, Fig. 6) similar to those used for infants’ cradles. The shape of the walls is shown in Fig. 6, which is a section of the apparatus. The method of using it is as follows:

The gravel is shovelled into the riddle-box, A, the bottom of which consists of ½-inch mesh screen ; the workman sits by the side of the machine and rocks it with one hand, while he pours on water by means of a dipper filled from a water-hole with the other. The dirt is disintegrated and carried through the riddle, and falls on the apron, B, which consists of blanketing, canvas or wood. Here some fine gold is caught, and the dirt then passes out from back to front over the bottom, which is slightly inclined towards the front, and the coarse gold, black sand, &c., is caught in two or three riffles, C, consisting of transverse strips of wood each of about 1 inch in height, to which mercury is sometimes added to assist in retaining the gold. The rocking motion not only assists in the disintegration of the dirt, which is affected by the water, aided by the stones, but also prevents the sand from packing behind the riffles; in the event of this happening gold would pass over the surface of the sand and be lost. Consequently the rocking should be quite continuous, since, after every pause, the sand in the riffles must be stirred up before recommencing. It is, therefore, desirable for two men to work together at the cradle, one to carry the gravel and charge it into the hopper, and to remove the large stones from the latter by hand, while the other man rocks the cradle and pours on water. It requires three or four parts of water to wash one part of gravel, and it is, therefore, better to carry the ore to water than to carry water to the ore. When a cleanup of the cradle is desirable, the riddle is removed, the apron is taken out and washed in a bucket, and the accumulations behind the riffles are scraped out and panned. Most of the fine gold in the dirt is lost by the cradle, and two men working together can only wash from 3 to 5 cubic yards per day, according to the nature of the dirt.

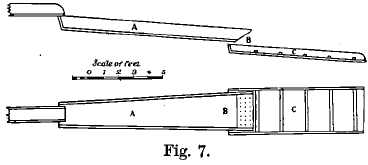

Long Tom Gold Sluice

The Long Tom, said to have been an importation from Georgia, was first used in Nevada County, California, in the latter part of 1849. It consists of a sluice-box or trough (A, Fig. 7) about 12 feet long, 20 inches wide at the upper end, and 30 inches at the lower end, and 9 inches deep, with an inclination of about 1 inch to the foot.  The lower end of the trough is cut off at an angle of about 45° and closed by a screen of sheet-iron, B, in which a number of half-inch holes are punched so that the fine dirt is allowed to pass through while the stones are retained. Below the screen is the upper end of the riffle-box, C, which is usually about 9 feet long, 3 feet wide, and at about the same inclination as the upper trough. It is fitted with several riffles, which are sometimes supplied with mercury. In working, a stream of water enters at the upper end of the sluice-box, into which gravel is continually shoveled, while a man breaks up the lumps with a fork, removes the large stones, and puddles the lumps of clay. Two to four men can work at one tom, and wash about five times as much in a day as can be done by one or two men with the cradle. Only the coarse gold is caught, and the machine is only suitable for washing small quantities of rich dirt where there is a plentiful supply of water. The material caught by the riffles is scraped out occasionally and panned, but the riffle-box is too short for the close saving of the gold.

The lower end of the trough is cut off at an angle of about 45° and closed by a screen of sheet-iron, B, in which a number of half-inch holes are punched so that the fine dirt is allowed to pass through while the stones are retained. Below the screen is the upper end of the riffle-box, C, which is usually about 9 feet long, 3 feet wide, and at about the same inclination as the upper trough. It is fitted with several riffles, which are sometimes supplied with mercury. In working, a stream of water enters at the upper end of the sluice-box, into which gravel is continually shoveled, while a man breaks up the lumps with a fork, removes the large stones, and puddles the lumps of clay. Two to four men can work at one tom, and wash about five times as much in a day as can be done by one or two men with the cradle. Only the coarse gold is caught, and the machine is only suitable for washing small quantities of rich dirt where there is a plentiful supply of water. The material caught by the riffles is scraped out occasionally and panned, but the riffle-box is too short for the close saving of the gold.

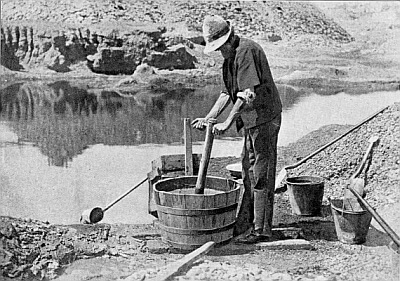

The Puddling-tub

The Puddling-tub, when water is scarce, as was the case in many places in Australia where rich gravels were found, the long-tom is inadmissible, and the puddling-tub is resorted to. This is particularly well adapted for washing clays and is still used to disintegrate lumps of clay encountered in sluicing operations. It consists of one half of a barrel which has been sawn in two; into this, the dirt is dumped and stirred up with water by means of a rake, until all the clay is held in suspension in the water, when a plug a few inches from the bottom is removed, and the slime run off. The operation is repeated until the tub is filled with gravel and sand to the level of the plug-hole and this residue is then shovelled out and washed by the pan, the cradle, or by sluicing. Large boxes were used in Australia in this way in the early days, the rakes being worked by horse or steam-power; in 1860 no less than 3,858 boxes, worked by horses, were in use in Victoria alone.

Gold Cradle

The cradle, long-tom, and puddling-tub are now little used in districts where work has been carried on for a long time except by the Chinese, who gain a precarious livelihood with their help by washing over the heaps of tailings accumulated from sluicing or hydraulic mining operations in Australia and California.

In new districts, however, for a short time after shallow deposits have been discovered, they are still extensively used. On the Klondike and at Cape Home, for example, thousands of diggers used them, latter-day improvements on the old cradle being especially numerous.

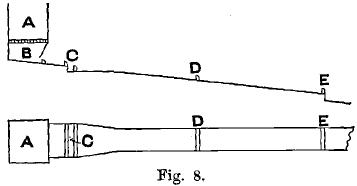

Siberian Trough

In Siberia, in the Urals, and in the valleys of the Obi, the Yenisei, and the Lena, individual workers still exclusively use a trough, which differs from the long-tom mainly in requiring more constant attention on the part of the operator, and which resembles the old German buddle. The trough consists of a rectangular box open above and at one end.

When sandy gravels are being treated, the bottom of the disintegration box (A, Fig. 8), which is about 40 inches square, is made of a perforated screen of wood or sheet-iron, having holes of from ½ inch to 1 inch in diameter. The dirt is shoveled into this box, and, contrary to cradle-practice, if the gold is present in fine flakes, mercury is added here also, the amount depending on the richness of the auriferous material as determined by assay, the proportion used, however, being never more than 10 of mercury to 1 of gold. Water is directed upon the charge in the box, either by pipes from a reservoir or more often by pumping, and the fine material is carried through the screen and falls onto the table, B, while the pebbles are collected by hand and thrown away. If the clay is being treated, no screen is used; the lumps are puddled in the box, and the mud carried over by an overflow of water. The table is slightly inclined, about 20 feet long, and, for the greater part of its length, is about 20 inches wide. It is furnished with five riffles, of which two (C) near the top are about 2 inches high, while the others (D, E) are of less height. The disintegration of the sand is completed on the table with the aid of a small rake continually used by the workman. When disintegration is complete, the stream of water is diminished in amount, and the workman continues to rabble the sands which have accumulated above the riffles, pushing the contents of the lower riffles up the table again, until the water runs clear, and little except pyrites is left behind the riffles where the so-called “ grey concentrates ” accumulate. These are either concentrated further on the same table or removed and worked on a smaller table. In either case, the stream of water is still further reduced, being graduated so as to carry away the last particles of quartz, together with all materials of moderate weight, such as garnets, rutile, tourmaline, and even all the fine pyrites. If mercury has not been added previously, it is sprinkled on before this last operation, unless the gold is very coarse, when no mercury is added at any stage of the proceedings.

The “black concentrates,” thus obtained, consist entirely of amalgam, magnetite, and large grains of pyrites. The final operation, by which the amalgam is separated, is the most difficult and requires the greatest amount of skill on the part of the operator. The material is worked on the same table with very little water, with the aid of a small rake, or more often with the hand of the workman, who kneels down by the trough for the purpose. Finally, all the pyrites having been washed away, the magnetite is removed with a magnet, and the amalgam collected. The tailings from the black concentrates are treated over again, together with the grey concentrates.

The apparatus just described treats about 500 lbs. of sand at one time and can be worked by one man, but usually gives employment to four people (frequently three of those are women), who can treat about 5 tons of sand per day. The degree of success attained depends largely on the skill of the workman; in Siberia and Russia the art is handed down from father to son, certain families devoting their whole lives to the work during many generations. These workmen attain such a degree of dexterity in the use of the trough, that practically the whole of the valuable contents of the gravels treated is extracted by them, but the work is only suited to those who are content with small earnings.

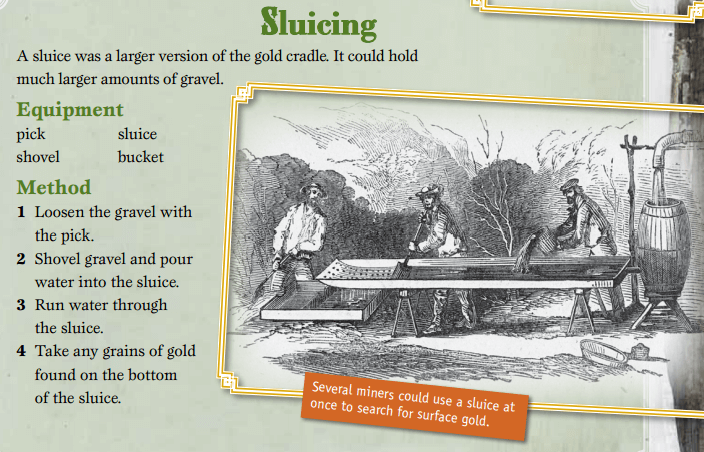

Gold Sluice

The sluice has replaced all these implements for washing the gravel from shallow placers, where water is abundant. Sluices are constructed of “boxes,” each of which resembles the upper part of the long-tom. The bottom of each box is made of rough boards, about 12 feet long, cut 4 inches wider at one end than at the other; the total width is usually from 16 to 18 inches, while the sides are 8 or 10 inches high. It has often been pointed out that sluice boxes are usually made too narrow so that the current is too deep, and fine gold is lost, while the flow is unduly checked by the sides, thus creating undesirable eddies. The box is held together with nails, and no attempt is made to render it water-tight, as the swelling, caused by the absorption of water, and the filling up of chinks with sand and clay soon stops all leakages. The narrow end of the box fits into the wide end of that next below it, and so a sluice, made up of hundreds of boxes, can be readily put up or taken down and moved to another locality.

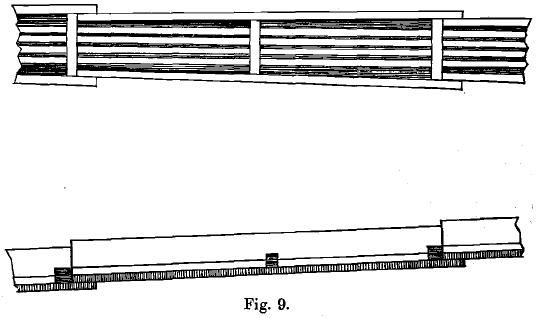

In all but the smallest and cheapest sluice boxes, extra strips of wood are affixed to the sides so as to protect them from the wear caused by the attrition of the stones and gravel carried through by the current. When worn thin, these strips are replaced. The bottom is similarly protected by riffle bars, whose main function is to catch the gold. Many different kinds of riffle bars are used. The simplest are strips of cut wood or fir poles 3 inches in diameter and about 6 feet long. They are usually placed longitudinally and are wedged in the boxes at a distance of 1 or 2 inches apart by means of transverse bars so that two sets of riffles are placed in each box in the manner shown in Fig. 9, which represents the whole of one box and parts of two others. The depressions or riffles proper thus formed between the bars are well adapted to intercept all heavy particles that pass down the sluice, such as gold, mercury, amalgam, pyrites, &c., which gravitate to the bottom of the stream. Sometimes the riffles are placed transversely, and sometimes for a short distance in a zig-zag fashion. This arrangement does not retain anything but affords a better chance of amalgamating the gold, which, together with the mercury (in this case fed in constantly), slides down the inclined riffles from side to side of the sluice, having sunk to the bottom by virtue of its high specific gravity.

When all is ready, a stream of water is turned into the head of the sluice, where the dirt is shoveled in also. The amount of dirt shoveled in per man depends on the height of the lift and the nature of the soil, as well as on the laborer. It varies from 3 to 7 cubic yards per diem and should average 5 or 6. The first gravel sluiced fills up most of the riffle depressions, leaving enough inequalities of the surface, however, to intercept and retain the mercury.

The length of the sluice varies with the consistency of the gravel, the fineness of the gold, the capital available, and the fall of the ground. It must be sufficient to complete the disintegration and then to catch the gold. The length may be adjusted by experiment; if, in the clean-up, the lowest boxes yield much amalgam, an addition to the length is necessary, while if they yield none, the sluice may be shortened by the removal of one or more boxes. Even in the latter case, however, the tailings would almost certainly contain some fine gold. The grade of the sluice is measured by inches per box so that a grade of “12 inches” means one of 12 inches in 12 feet. The usual grade is about 6 inches per box, but it varies from 2 inches to 20 inches per box, depending:

The length of the sluice varies with the consistency of the gravel, the fineness of the gold, the capital available, and the fall of the ground. It must be sufficient to complete the disintegration and then to catch the gold. The length may be adjusted by experiment; if, in the clean-up, the lowest boxes yield much amalgam, an addition to the length is necessary, while if they yield none, the sluice may be shortened by the removal of one or more boxes. Even in the latter case, however, the tailings would almost certainly contain some fine gold. The grade of the sluice is measured by inches per box so that a grade of “12 inches” means one of 12 inches in 12 feet. The usual grade is about 6 inches per box, but it varies from 2 inches to 20 inches per box, depending:

- On the fall of the ground, since the sluice cannot be raised far above it, nor sunk deep into it, owing to the increased expense thereby occasioned.

- On the nature of the dirt to be washed.—Tough, tenacious, clayey, or cemented gravels require higher grades to effect their disintegration than loose material. Instead of being disintegrated, clay sometimes becomes aggregated into balls, which roll down the sluices, picking up particles of gold previously caught in the riffles, and these lumps of clay must be removed by hand and puddled. There must be sufficient grade to enable the water to carry away all but the largest stones, so as to avoid unnecessary hand-picking, but on the other hand, while coarse gold is readily caught, fine particles are lost if the current is too rapid.

- On the quantity of water available.—The reduction of the grade lessens the duty of the water, so that if the supply of the latter is short or costly, the grade is made as steep as possible, consistent with saving a fair proportion of the gold. A steep grade reduces the necessary length of the sluice, as disintegration takes place sooner. Since a steep grade, a rapid flow, and deep currents are best suited to effect speedy and thorough disintegration of the gravel, while a low grade and slow and shallow currents are best adapted for saving the gold, the upper part of a sluice, for a sufficient distance to effect the complete disintegration of the gravel, is sometimes made of higher grades, or with narrower boxes than the lower part, which is occupied solely in catching the gold. When this is done additional supplies of water should be introduced at the point where the change is made, otherwise, the duty of the water is reduced, the sand packs in the angle where the grade is altered, and constant attention is required to prevent the stream from overflowing.

Sluice Mudbox & Grizzly

The requirements of disintegration and gold-saving are more often supplied by “drops,” “mud-boxes,” and “undercurrents.” A vertical fall of the pulp constitutes a drop, which is arranged as follows:

The sluice terminates in a “grizzly,” or inclined grating made of parallel iron bars placed longitudinally to the stream, and from 1 to 6 inches or more apart, according to the exigencies of the case. All the water and fine stuff pass through the grizzly and fall a distance of from 1 to 10 feet into a sluice below. The larger stones or boulders roll down the inclined bars and are shot over a precipice (if possible) or on to a steep slope outside the sluice, as, unless some arrangement for removing these rocks is made, they will accumulate until they can no longer roll off the grizzly. The higher the fall, the more effectively it acts in causing disintegration. Sometimes, near the head of a sluice, the grizzly is omitted from a fall, and the boulders are retained to help in breaking up the gravel. The chief disadvantage in permitting them to remain with the rest of the gravel lies in the fact that they wear out the sluice, and that much water is required to wash them down.

A mud-box is merely a wide part of the sluice, 2½ or 3 feet wide, and 12 or more feet long, at which a man is stationed to break up and puddle the lumps. A better, but more expensive, the appliance is a trommel or a pan with a mechanical stirrer.

The undercurrent is often used in conjunction with a drop. A grizzly with bars placed close together allows most of the water and fine material to pass through, while the coarse stuff is carried over and falls into the main sluice below. The fine material is carried off by a short sluice placed at right angles to the general direction of the main sluice and is discharged into the upper end of a large broad box from three to ten times as wide as the sluice, and with its long diameter parallel to the main sluice. A number of check-boards help to distribute the stream evenly over the whole width of the box. This box, to which the name undercurrent is often given, although it properly belongs to the whole arrangement, is usually of a higher grade than the sluice, having a fall of 10 or 15 inches per box, so that a broad shallow stream flows over its surface. It is plentifully supplied with riffles and mercury and is intended to catch fine gold and amalgam. The tailings from the undercurrent are discharged into the main sluice below the drop.

Both grizzlies and undercurrents are used more frequently in hydraulic mining than in shallow placer sluicing, in which the large stones are usually removed by a man with a blunt pronged fork, who also either breaks up the lumps of clay or removes them and puddles them in tubs.

Using Mercury in Sluicing

Mercury is added at the head of the sluice after washing has been in progress for a sufficiently long time for all leakages to have been stopped, and for the lowest depressions to have been filled in with sand. The mercury is sometimes sprinkled into the sluice and sometimes poured into the riffles. The amount added varies with the richness of the dirt and the magnitude of the operations, enough being added to dissolve the amalgam formed. It is carried down the sluice and lodges in the riffles, the greater part being retained in the first few boxes. Fresh supplies are introduced every few hours at the head of the sluice, and sometimes at various points lower down the sluice also; in particular, mercury is added to the undercurrents, as it is especially valuable in catching the finer particles of gold which would otherwise be lost, whilst coarse gold can in great part be saved without mercury. Sometimes the latter is forced into the substance of the wooden riffles by driving an iron gas pipe into the wood and filling it up with mercury, which is forced by the pressure of the column through the pores of the wood. The amalgam then forms on the surface and in the interstices of the blocks, and in cleaning-up, this is scraped off. A better plan is to use amalgamated copper plates, which is now often done. These resemble the plates used in stamp batteries, described in Chapter vi.

Cleaning a Sluice Box from its Gold

The length of each “ run,” at the end of which the boxes are cleaned up, varies, according to the richness of the gravel, from a day to a whole season, and is usually a week.

The upper part of the sluice, which retains most of the gold, is usually cleaned up more frequently than the remainder. A clean-up is begun by discontinuing the supply of gravel and letting the water continue to flow until it passes through the sluice quite clear. The first six or eight sets of riffle bars are then taken up, and the sand, mercury, and amalgam washed down, all the latter being caught by the first riffle left in. It is scooped out thence by a wooden ladle or iron spoon into a bucket, and the rich sand is collected and panned. The next few riffle bars are now taken up, and so on, or alternatively, the work may be begun on several sections at the same time. Lastly, the whole sluice is carefully searched over, and particles of amalgam or mercury picked out of every crevice where they have lodged by spoons, penknives, &c.

The amalgam thus collected is stirred with fresh quicksilver in “amalgam kettles” or buckets, and the black sand and other foreign matter skimmed off. It is then strained through chamois leather or drilling, liquid mercury passing through and pasty amalgam being retained by the skin. The amalgam is well squeezed and then retorted. The retorts used in well-conducted enterprises are similar to those in use in stamp mills, described in Chapter vii. Amalgam obtained as the result of operations on a small scale, however, is often merely heated on a shovel over an ordinary fire, the mercury being driven off and lost.

Tail Race

The tailings from sluicing operations on low ground which has not much fall are removed through a covered – in the wooden sluice, or, better still, through a large iron pipe. The work proceeds in the upstream direction, and the worthless material stripped from above the pay-gravel is thrown on the top of the tail race, which thus passes through a mound of earth and discharges into the open-air lower down the valley. As the digging and sluicing progress upstream, the tail race is lengthened and the sluice boxes proper are conveyed further up the valley so as always to be near the auriferous material last uncovered. This method originated with the Chinese.

Tail Sluices are sometimes erected to intercept the tailings from one or several sluices with the object of collecting a further percentage of gold from the waste material. These tail sluices are made of much greater size than those described above, and in some cases pay for construction. The Kumara sludge channel, erected by the New Zealand Government to carry the tailings from the sluicing works of the district into the river, caught 957 ozs. of gold in the four years ending in 1891. This sluice is 3 feet 6 inches wide, and has a grade of 1 in 28, while the boxes which discharge into it are only 18 inches to 22 inches wide. Usually, in good work, the sluices are long enough to make the tailings too poor to be worked over again at a profit, except by the Chinese, until after they have been enriched by natural concentration in the rivers.

Ground Sluice

In some cases boarded sluice boxes are not used, but a stream of water is conducted to a little trench cut in the pay dirt, which is soon enlarged by the action of the water, while the banks are at the same time shoveled or prised by the pick or crowbar into the sluice. The gold is caught in the natural riffles afforded by the uneven wearing of the bed, or rocks may be added to arrest the gold, no mercury being used. Ground sluicing is only adopted where the supply water is precarious, or the season very short, so that violent rains cause floods that would sweep away sluice boxes, and then are succeeded by dry intervals during which the boxes would warp and crack. Only the coarse gold is saved, while the duty of the water is usually much less than in wooden sluices. After a time, usually, when the water gives out, the auriferous material is collected from the sluice and washed in a long-tom or cradle.

Booming

This method of sluicing is described by Pliny in his account of gold-washing in Spain in the first century. It is adopted when the water supply is insufficient for continuous operations. A dam with a light gate, capable of being easily lifted, is built just above the part of the valley where the auriferous gravel is situated. The water trickling down the valley accumulates behind the dam, and finally overflows at one point into a small rectangular box fastened to the end of a long lever. When full of water this box depresses its end of the lever and raises the dam-gate so that all the accumulated water rushes out at once and scours the valley bottom. As the box falls it empties itself of water, and the dam-gate returns to its original position by its own weight. This device is usually employed in connection with ground-sluicing, but a line of sluice-boxes might be used through which the sudden flood could carry gravel piled just above the head of the series.

Dry-Blowing

If no water can be obtained, it is sometimes profitable to concentrate pay-dirt by winnowing, tossing it in a pan until the lighter particles have been blown away, and finishing with mouth-blowing. It is of course a wasteful method of concentration. In West Australia the conditions are favorable to dry-blowing, winds being strong and constant and the air hot and dry. The method used there is to slowly empty a pan full of dirt into an empty pan placed on the ground. This operation is repeated again and again and is followed by tossing in a pan, by “ panning ” as though water were being used, and finally by mouth-blowing. The larger pieces of barren material are removed by hand at intervals.

Among machines used for the purpose, the simplest consist of flat screens supported on a frame and shaken by hand, the material falling through being winnowed by the wind. In other contrivances, a bellows is added worked by the same hand-mechanism by which the screens are shaken.

In some of the machines, the blast of air is used to keep the sand partly in suspension, while it is moved by gravity down an inclined table which is furnished with riffles. The auriferous material must be quite dry or perfect disintegration cannot be accomplished. In a typical dry washer, the gravel is first made to pass through shaking screens, the mesh of which is adapted to the character of the material. The object of the screen is to eliminate the larger fragments, which are usually barren. The shaking screen delivers the material onto an inclined table formed of a wire-screen, covered with light canvas or some similar material through which are forced pulsating blasts of air. These sudden puffs throw up the sand and let it settle again alternately, and as a result, the light material works down the table, while the gold is retained by the riffles, being too heavy to be tossed over them by the air.

In Edison’s dry washer, the auriferous sand falls vertically and is acted on by a horizontal current of air supplied by a fan, care being taken to avoid puffs and to keep the current constant. The air passes through a screen to eliminate eddies. The lighter material is deflected from its course more than the gold. As the gold is of different shapes and sizes, the gravel is carefully sized by screening. At a mill near Santa Fe, in New Mexico, where the gravel contained from 3 c. to 35 c. in gold per cubic yard, about 95 percent, of the gold was saved. The iron was removed by a magnetic separator.

Gold Flycatchers

Flycatchers were invented in Australia for the purpose of catching the fine particles of gold, which, successfully evading the riffles of all sluices, float down on the surface of the rivers. These devices consist of weirs constructed on piles driven into the river bed, and stretching across from bank to bank of the river. Boards covered with blanketing or coarse gunny-sacking are attached to the weirs and collect all particles floating on the surface of the water. At intervals, the blankets are taken up and washed in a tank. These flycatchers soon pay for their cost of construction on many rivers but are liable to be damaged by floods, and by being used as bridges by men and animals.