Table of Contents

Cyanide Precipitation Equipment is designed to meet the demands of cyanide plants for a low cost, efficient method of precipitating gold and silver from a cyanide solution. Metallurgical results obtained with this equipment have proved highly satisfactory and usually compare favorably with results obtained with more complicated processes although the machines are simple and inexpensive.

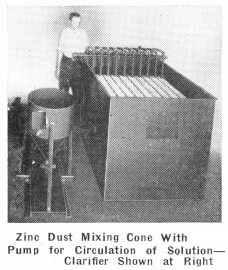

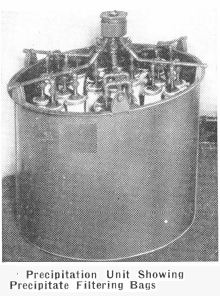

Equipment includes a pregnant solution tank, clarifier, solution pump, zinc dust feeder and mixing cone, a precipitation agitator where required, a second solution pump, precipitation unit, (including precipitate filtering bags), and a barren solution storage tank. Highest quality materials are used in the fabrication of each unit which assures continuous, trouble- free, and lowest cost operation of any size plant.

Cyanide Precipitation Equipment will provide plants to handle from 25 to 600 tons of solution per day. Complete plants for precipitating larger quantities of solution can be worked out according to the value and type of ore to be cyanided and the tonnage to be handled. Laboratory testing is the most accurate and reliable method of determining these factors before the necessary investment is made and a commercial plant installed.

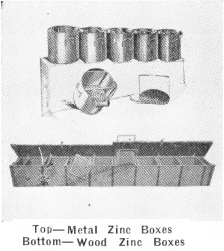

Zinc Box Precipitation Equipment

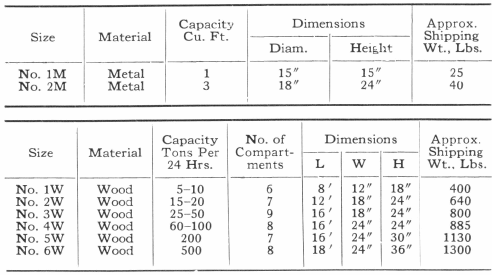

Zinc Box Precipitation Equipment includes zinc boxes of either rectangular wood, or round metal construction.

The use of the round metal box enables the user to handle each cell separately, which is an advantage when making a clean-up. It also gives an opportunity to increase capacity by adding more boxes.

Wood Zinc Boxes are constructed with deep compartments to compel the solution to pass through a deep bed of zinc shavings. Boxes are held together by iron rods which pass vertically and horizontally through the wood in such a manner that the solution cannot reach them. All compartments are furnished with improved screen shaving trays which afford maximum contact.

Zinc boxes are not recommended where the amount of precipitate is large. They can be used for low grade gold solutions to marked advantage because of their low initial cost, the accessory items necessary for their operation being very limited. For use of either wood or metal zinc boxes it is advisable to provide a zinc lathe, pump for recirculation of solution through zinc boxes, several large pregnant solution tanks, and washing tubs. A vacuum clean-up tank may be necessary for filtering precipitates from zinc boxes. Let us make recommendations for the type boxes and items of accessory equipment to best suit your needs.

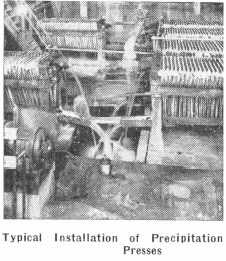

Precipitation Press

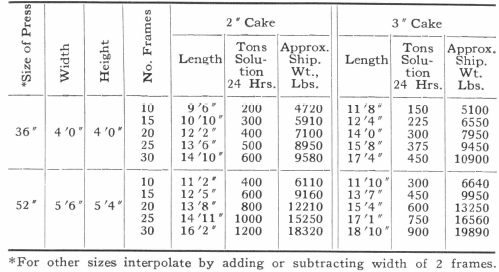

The Precipitation Press is available in various sizes; the number of plates and frames used depending upon the amount of precipitate to be filtered and the characteristics of the solution.

In the operation of this unit the pulp suspension is mixed with the precipitant and then pumped into the inlet of the filter press. The solution then flows into the triangular frames which are alternated with the plates. Plates have sides covered with a filter media and may be either recessed or flush, with either pyramid, corrugated, or other surface giving optimum drainage of barren solution and providing proper amount of support for filter media. Frames and plates are held tightly together by a heavy power screw and, with filter media between, a gasket-like joint is formed which prevents leakage. Precipitation takes place and pressure forces the solution through the filter cloth, the precipitate being left inside the frames. The barren solution emerges from the filter press through drain cocks or outlets in the plates. Periodically, plates and frames are removed from the filter press, cleaned, and precipitates refined for marketing as bullion.